Hood gad distributing board

A gas distribution plate and gas distribution technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of large air cap bubbles, defects in design methods, and abrasion of the side wall area of the fluidized bed of the gas distribution plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

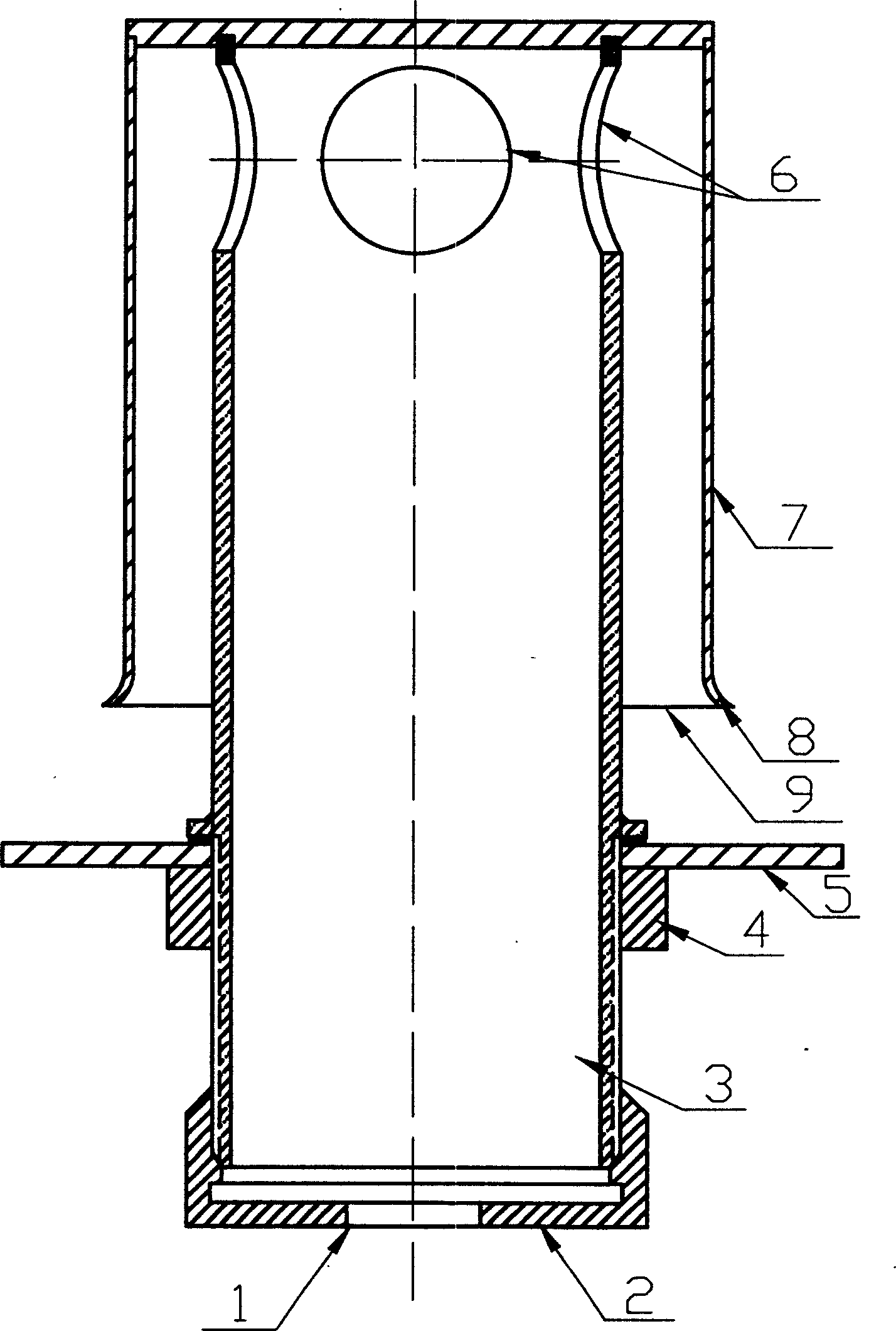

[0009] The specific structure and best implementation mode of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0010] As shown in the figure, the present invention mainly includes gas inlet 1, variable resistance opening nut 2, hood air intake inner tube 3, hood fixing nut 4, multiple gas jet holes 6, hood gas discharge outer tube 7, and gas outlet smooth transition Section 8 and so on constitute. The air intake inner tube 3 of the hood is fixed on the gas distribution motherboard 5 through the fixing nut 4, and the variable resistance opening nut 2 is a variable inner diameter nut, which is installed at the inlet end of the air intake inner tube 3 of the hood. The outlet end of the air intake inner tube 3 of the hood is installed with the outer tube 7 of the hood, and the outlet 8 of the outer tube is designed as a smooth transitional outlet, which not only reduces the momentum loss of the outlet gas, but also makes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com