Rib shaping mould

A technology of forming die and wire hook, applied in the field of machinery, can solve the problems of low production efficiency, high processing cost, many production equipment, etc., and achieve the effect of fast production speed, high work efficiency, and automatic production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

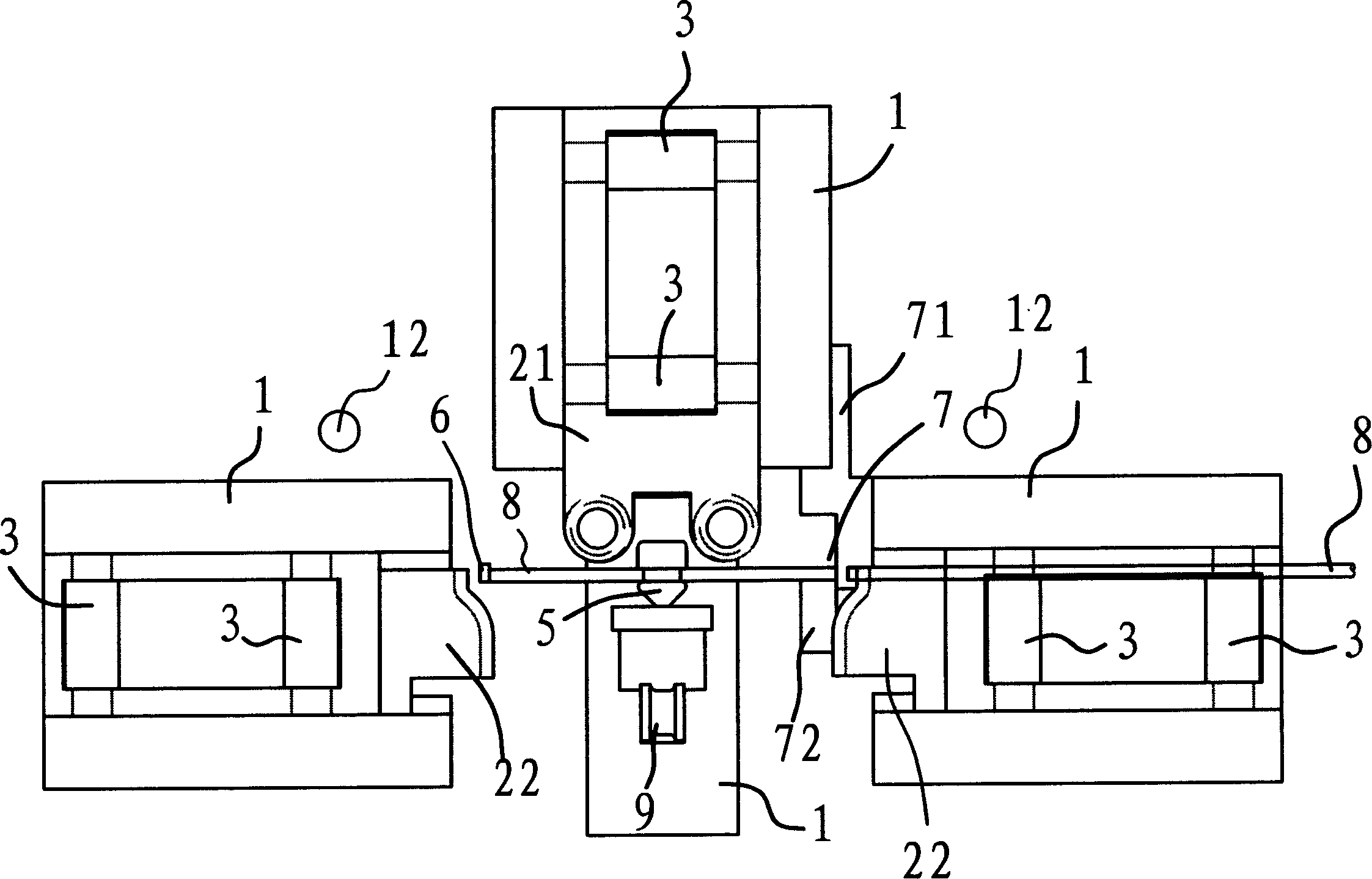

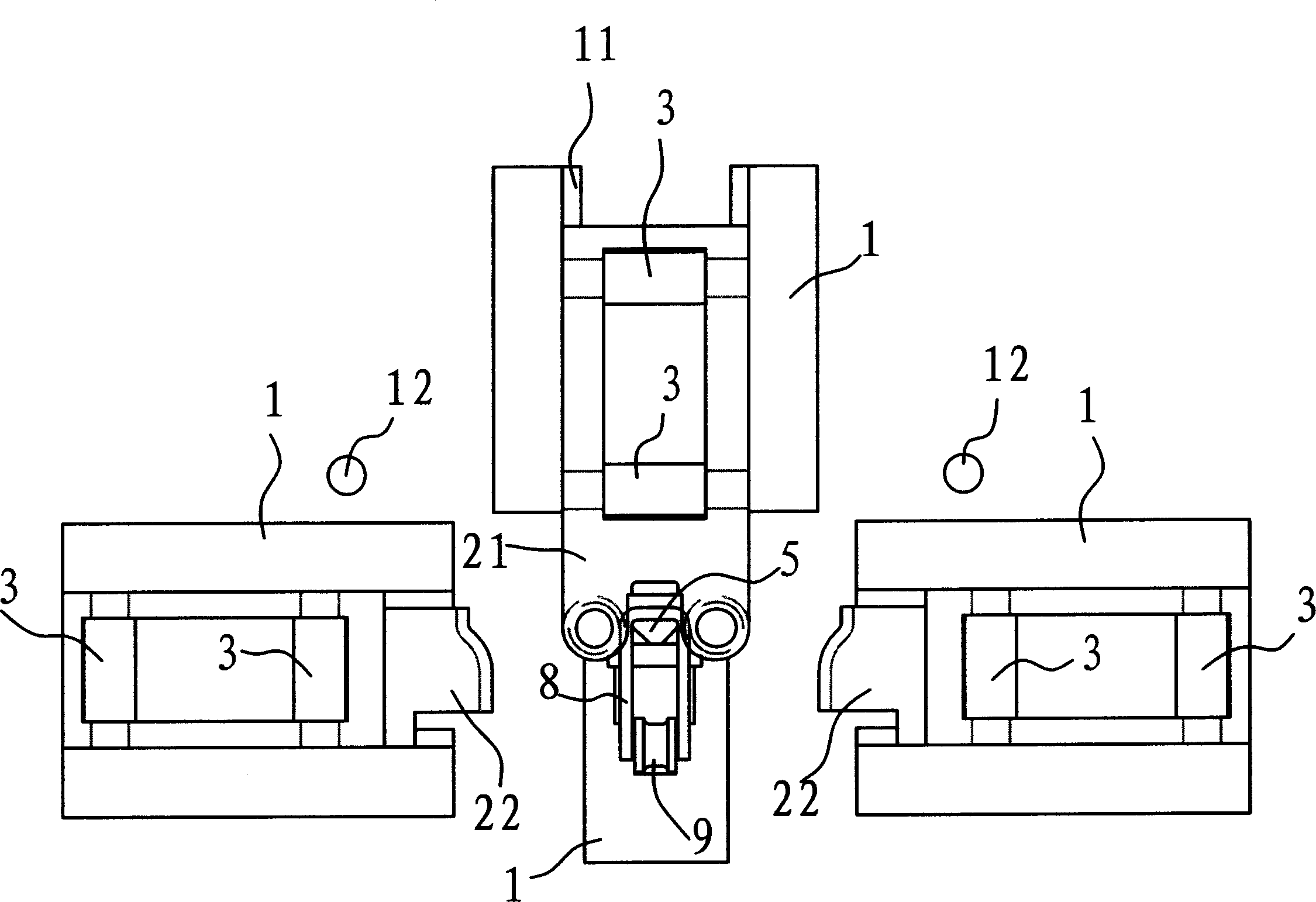

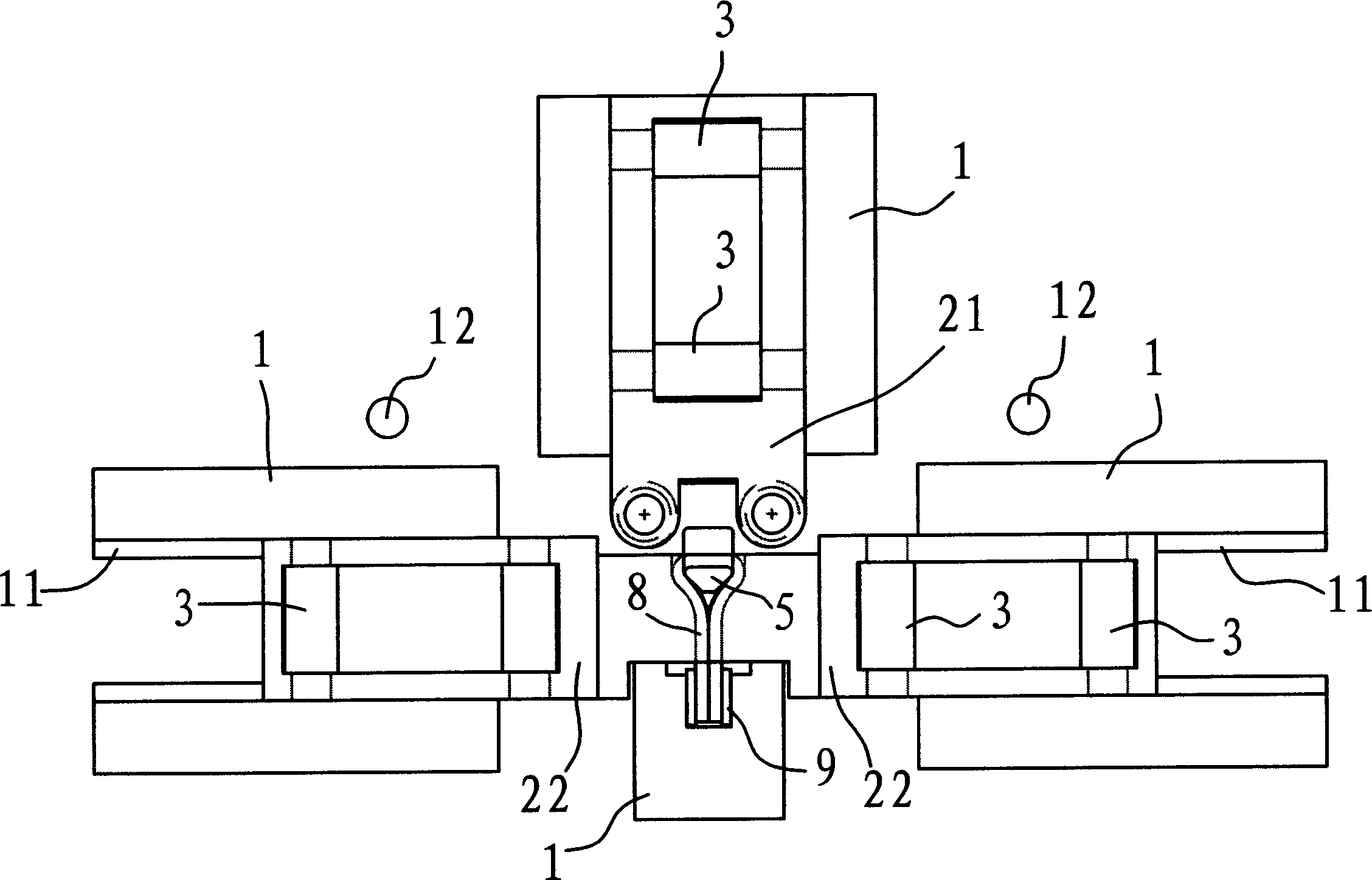

[0022] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the wire hook forming mold includes a base 1, a mold core 5 and each slider 2, wherein the slider 2 has a U-shaped slider 21 above the mold core 5, and two pressing joints on the left and right sides of the mold core 5. The slide block 22 and the forming punch 42 that is in front of the die core 5 . In this embodiment, the wire hook forming die also includes a wire cutting device 7 . The device 7 is made up of a lower die 72 below the wire rod 8 and an upper die 71 above the wire rod 8 , the lower die 72 is fixed on the base 1 , and the upper die 71 is fixed on the U-shaped slide block 21 .

[0023] Such as figure 1 As shown, a positioning plate 6 is provided on the other side of the U-shaped slider 21 , and the positioning plate 6 is fixed on the base 1 . After the wire rod 8 passed through the notch 51 of the cutting device 7 and the mold core 5 , its front end pressed against the positioning plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com