Electric rheological fluid vibration-absorber for vehicle engine

A technology of automobile engine and electrorheological fluid, which is applied in the direction of power plant, vehicle parts, vibration suppression adjustment, etc., can solve the problems of rigidity, damping unadjustable, narrow vibration frequency range, and affecting the service life of the vehicle for ride comfort, etc., to achieve Reducing ride discomfort and satisfying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] This embodiment is an electrorheological fluid shock absorber used in automobile engines.

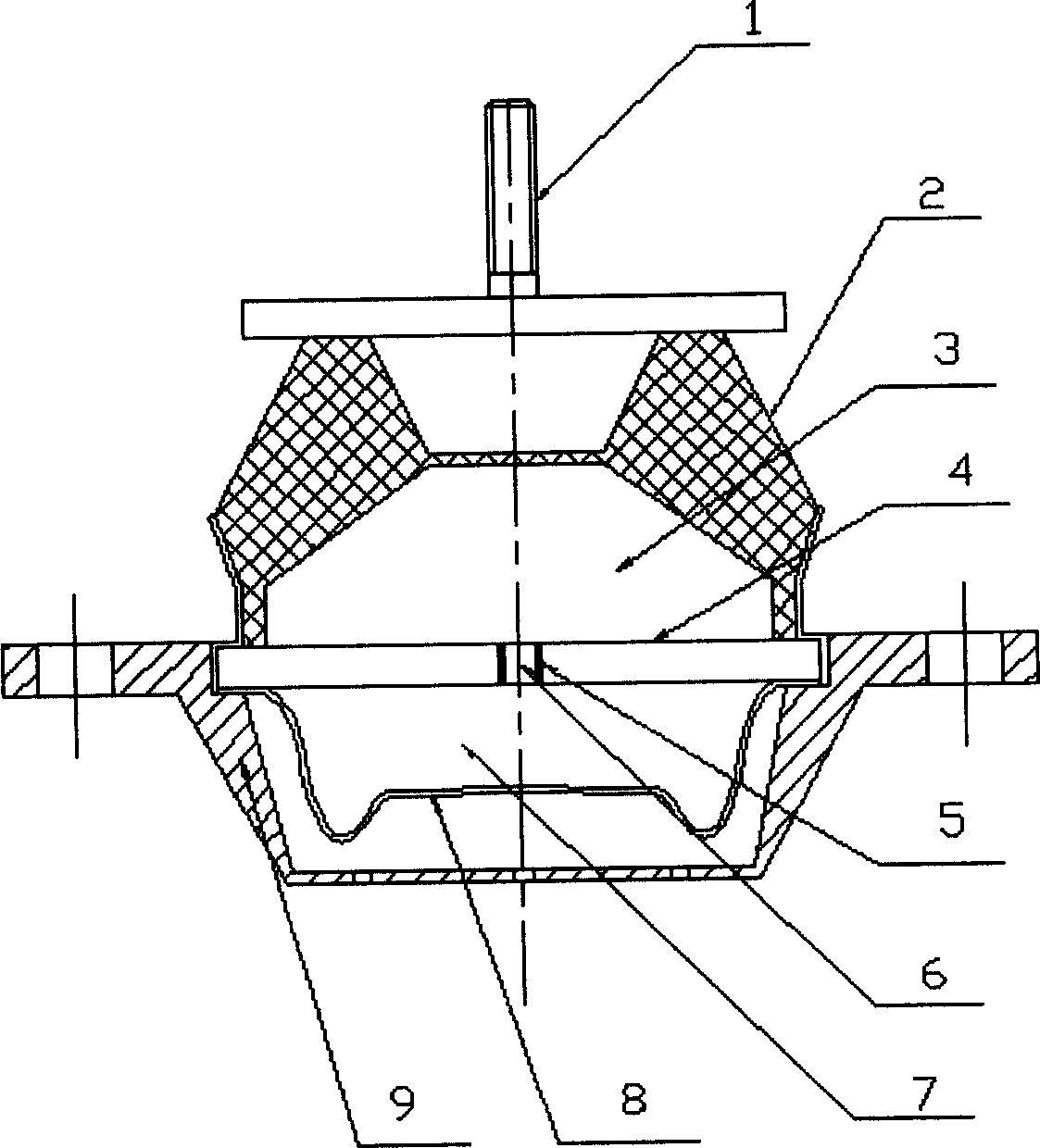

[0008] Such as figure 1 As shown, the main structure of this embodiment is: central bolt 1, upper end cover 2, upper working chamber 3, separator 4, electrode 5, damping channel 6, lower working chamber 7, elastic membrane 8, lower end cover 9.

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0010] The upper working chamber 3 with electrorheological fluid, which is composed of the upper end cover 2 and the partition plate 4 made of elastic material, is the elastic element of the vibration damping system. When it is subjected to external excitation, it can deform and change the upper working chamber. The volume of the cavity allows the electrorheological fluid to be discharged through the damping channel 6. Obviously, if the oil discharge of the upper working chamber is unobstructed, the stiffness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com