Screw tooth form of double-screw air compressor

An air compressor and twin-screw technology, applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of large leakage triangle area, poor sealing effect, long sealing line length, etc., and achieve small leakage triangle area , low noise and short sealing line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is described in detail.

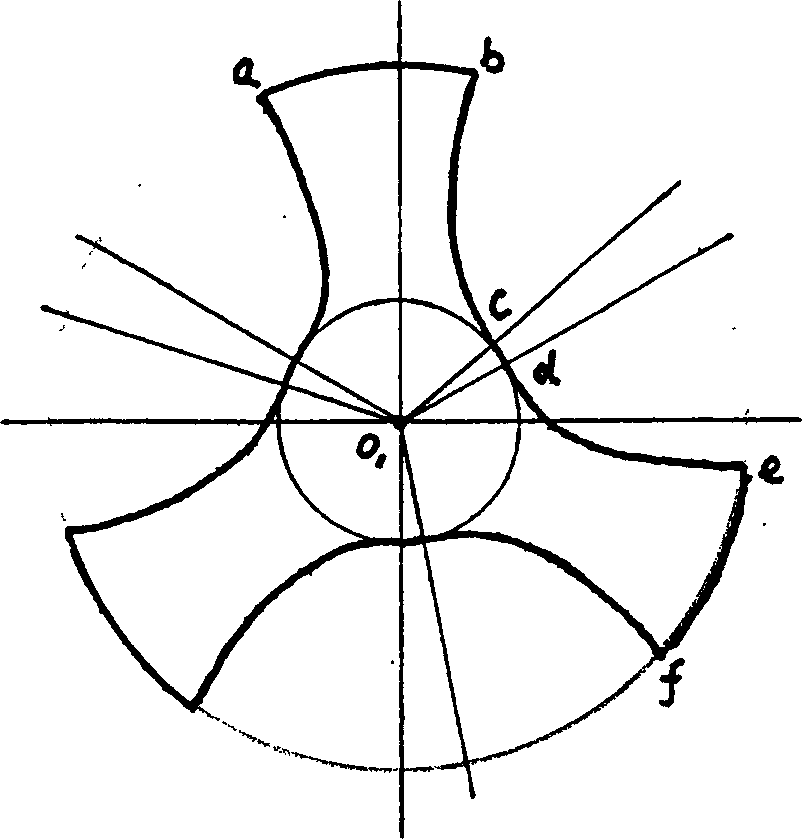

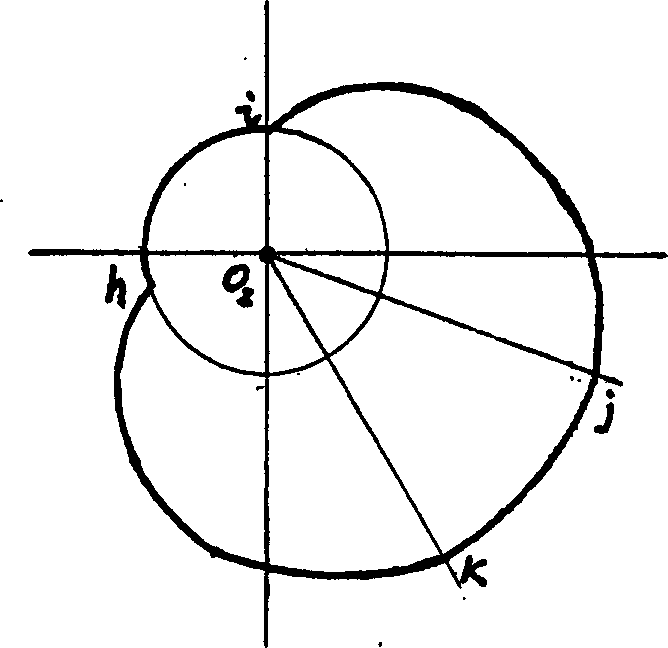

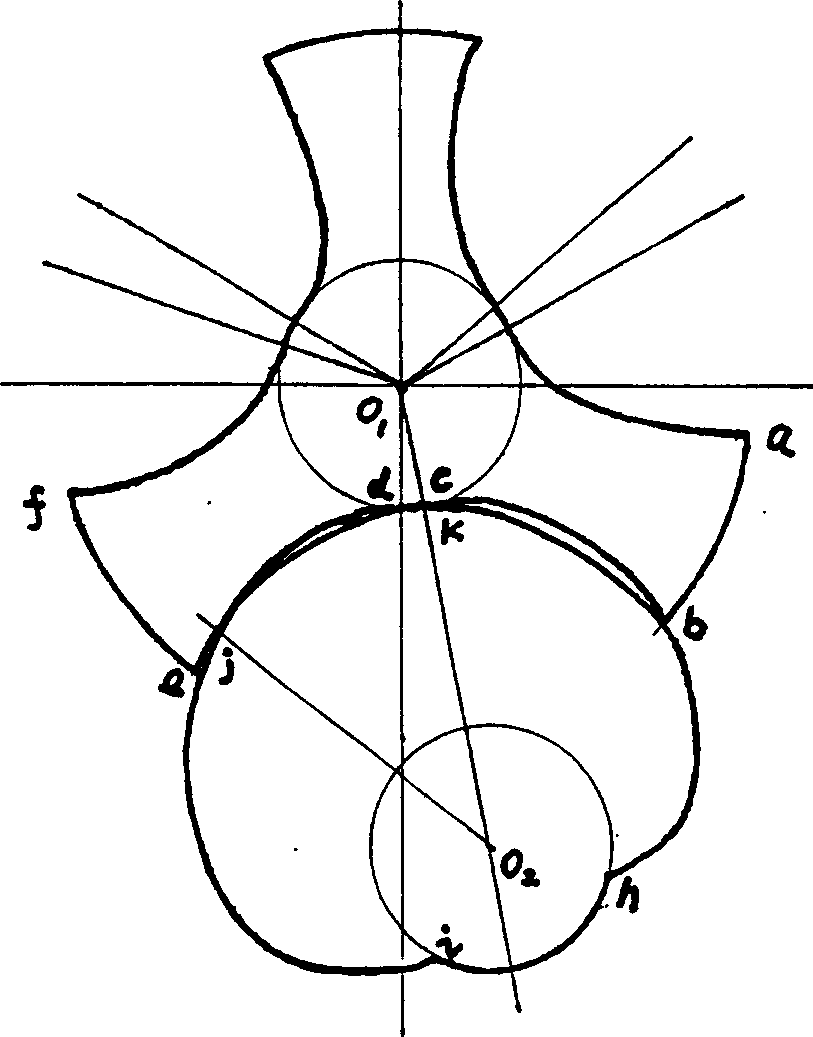

[0014] figure 1 The shape of the radial section of the three-start screw of the present invention is shown, and the tooth profile of each screw of the three-start screw is equal and uniformly distributed along the circumference. Addendum circle curve is the center o 1 , the arcs at both ends are arc ab and arc ef respectively, and the root circle curve on the opposite side of the addendum circle is the circle center o 1 The arc line cd of the arc (the radian of this arc is adjustable, and the limit value is zero), the point b at one end of the arc line ab of the addendum and the point c at the end cd of the arc line cd of the root is composed of a generalized cycloid bc, and the root circle The point d at the other end of the arc line cd and the point e at the end of the arc line ef are formed by a generalized cycloid de. The radius of the addendum arc line ab is three tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com