Goods bag

A technology for storing bags and commodities, which is applied to bags, sacks, packaging, etc., can solve the problems of disorderly stacking, labor-intensive, labor-intensive, etc., and achieve the effect of saving time for sorting or cleaning, reducing labor costs, and saving placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

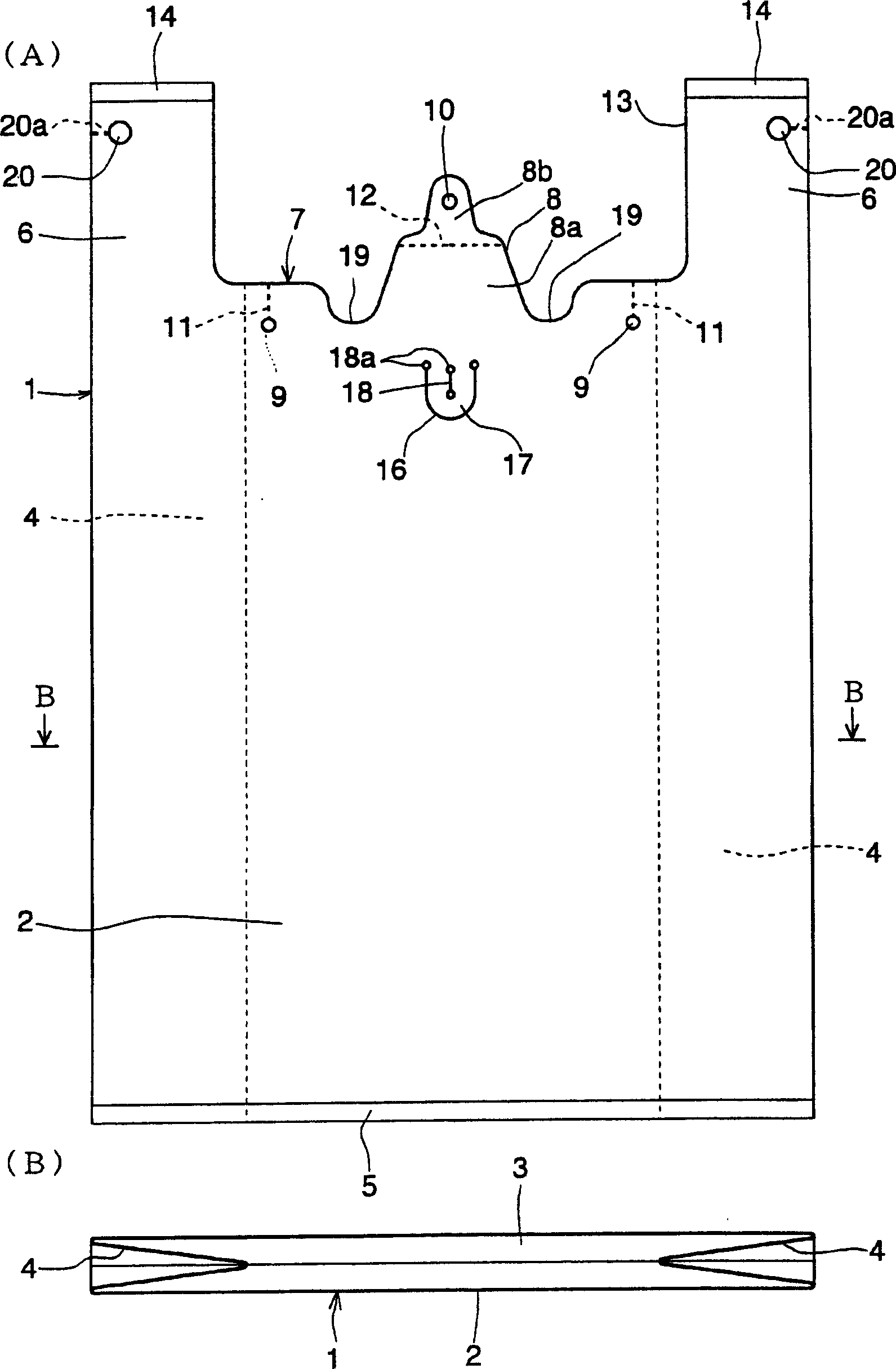

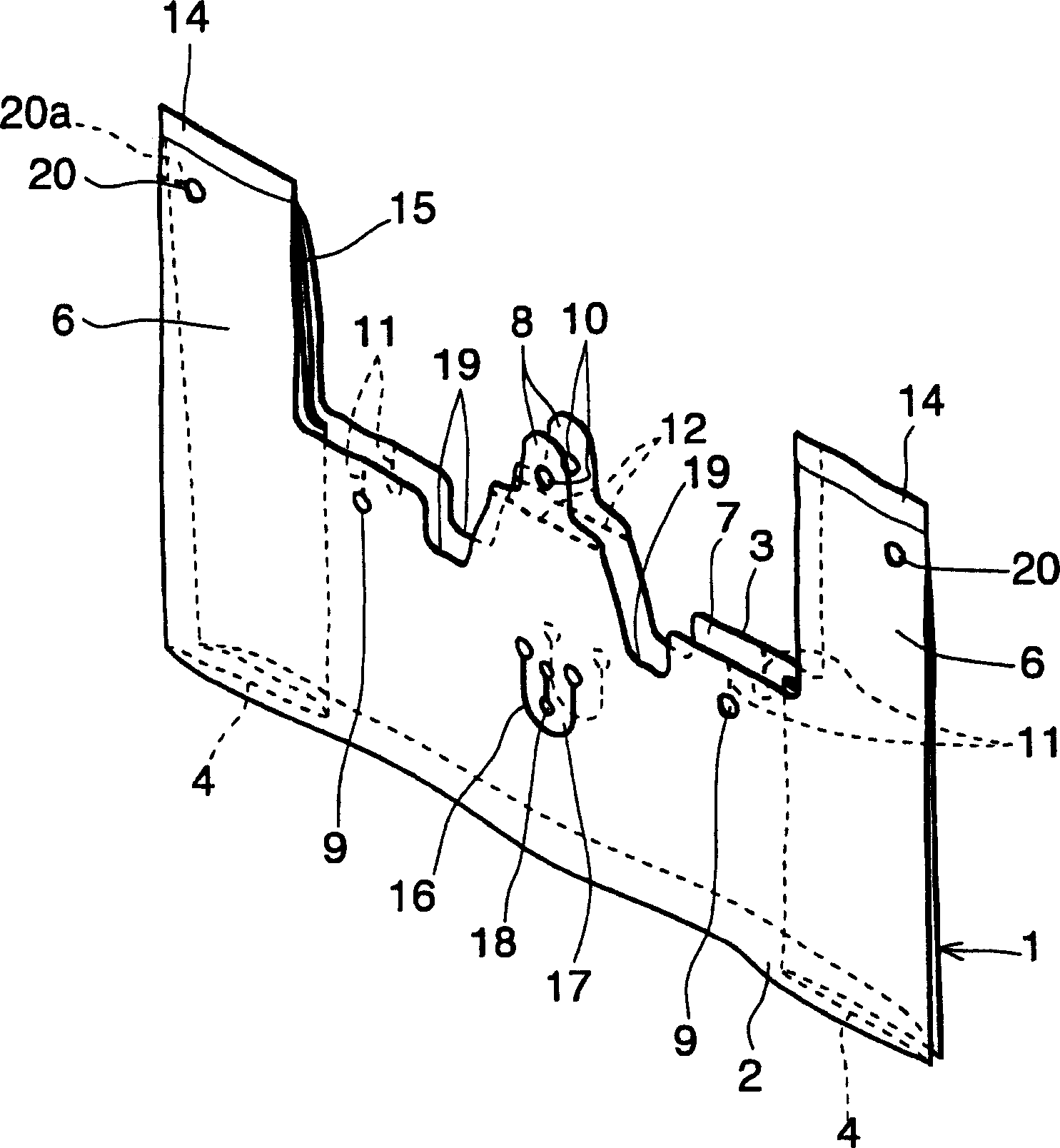

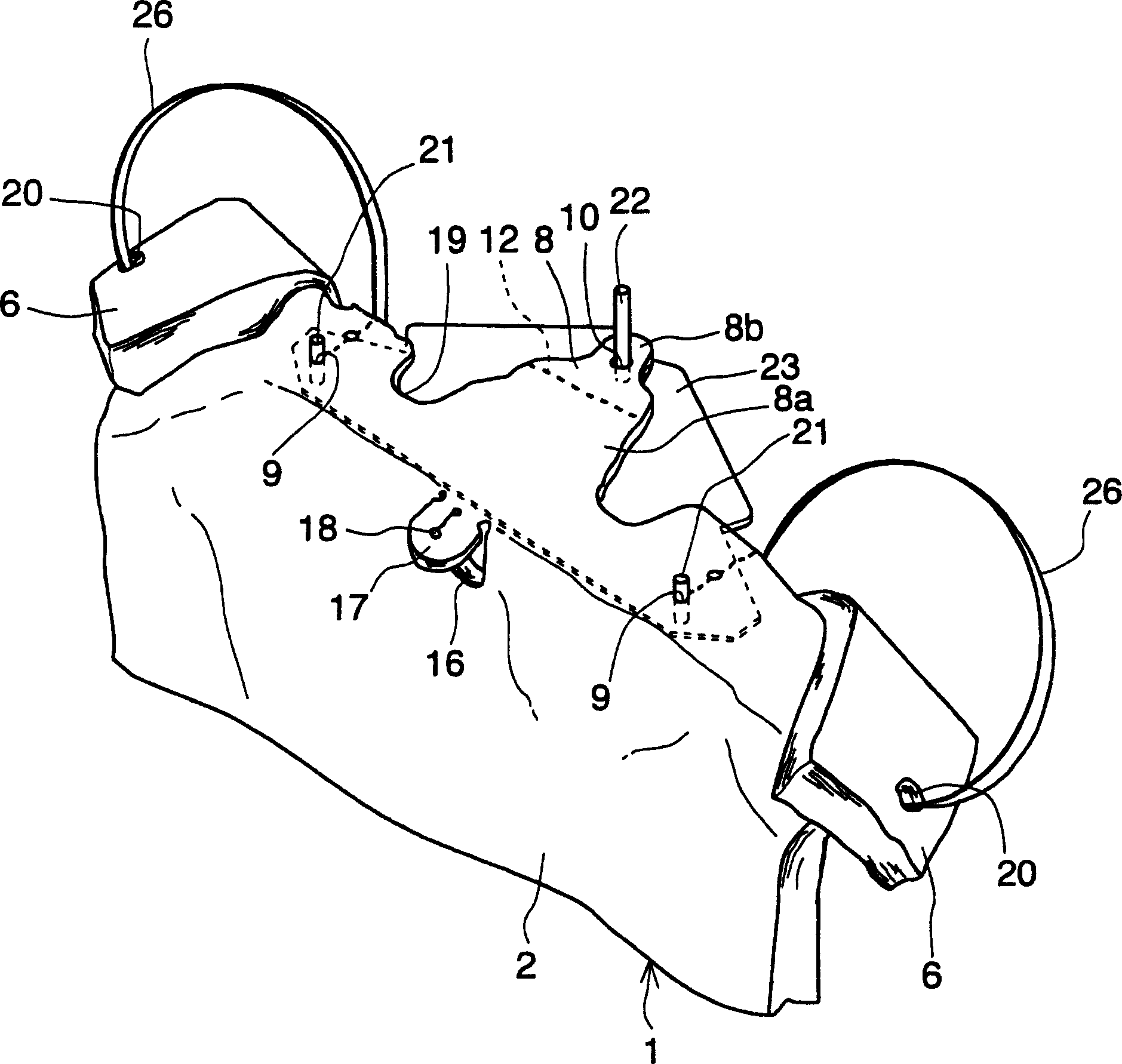

[0033] Using a synthetic resin cylindrical film, forming folded-in parts on both sides of the cylindrical material and folding it flat, sealing the lower ends of the surface film and the back film by welding, and cutting off the center of the surface film and the upper part of the back film. The upper end of the handle portion protruding upward is provided at the side position, and the tongue piece is provided at the central position to form a product storage bag. On the position and above-mentioned tongue piece, the hole for hanging is set respectively, tear seam is set between the hole for hanging provided on the upper end of above-mentioned surface film and back film and the upper end edge of surface film and back film, in the middle of above-mentioned tongue piece, in A tear line is provided along the width direction at a position lower than the hanging hole.

[0034] (Example)

[0035] As shown in the figure, in the product storage bag 1, both sides of the surface film 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com