Jp2005081297

A technology for cleaning the surface of devices and substrates, which is applied in the directions of identification devices, transportation and packaging, cleaning of flexible items, etc. It can solve the problems of long production time and large-scale production, and achieve the effect of shortening production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

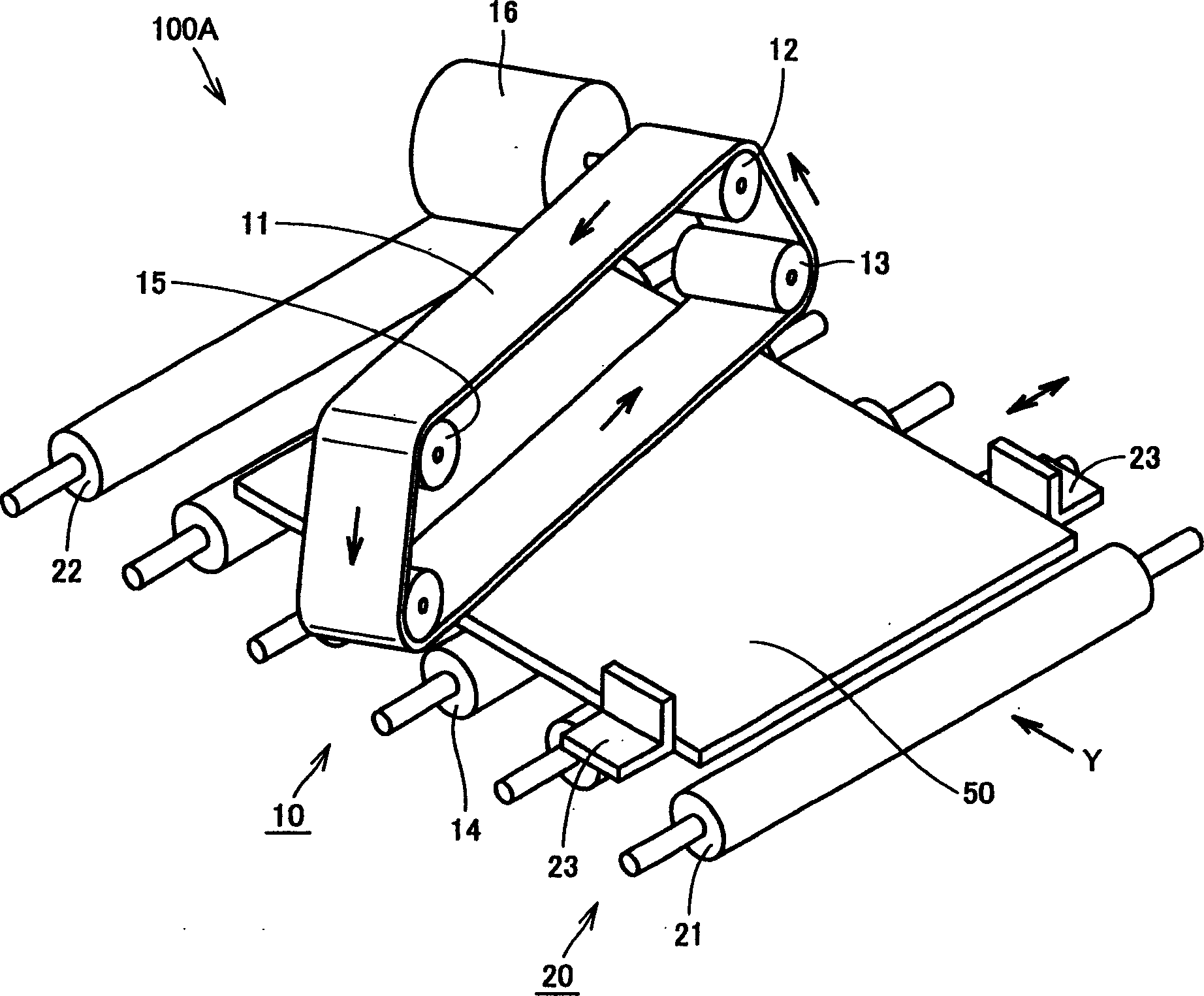

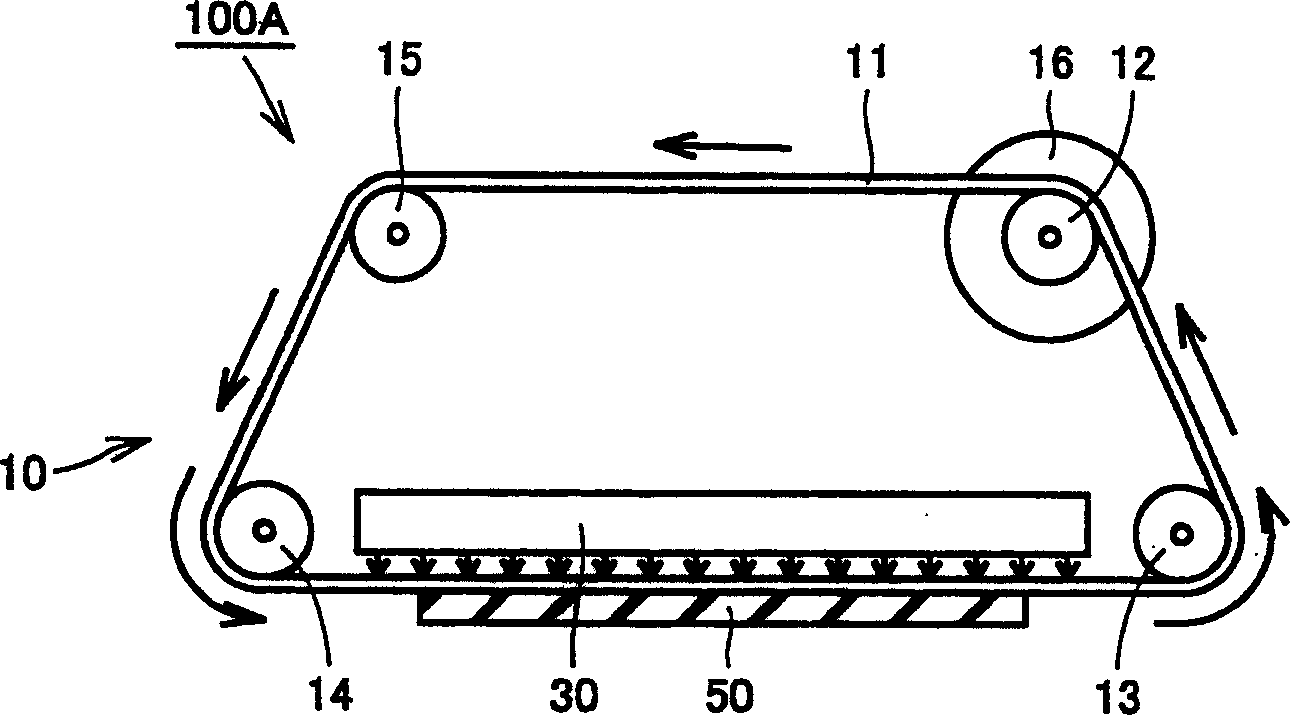

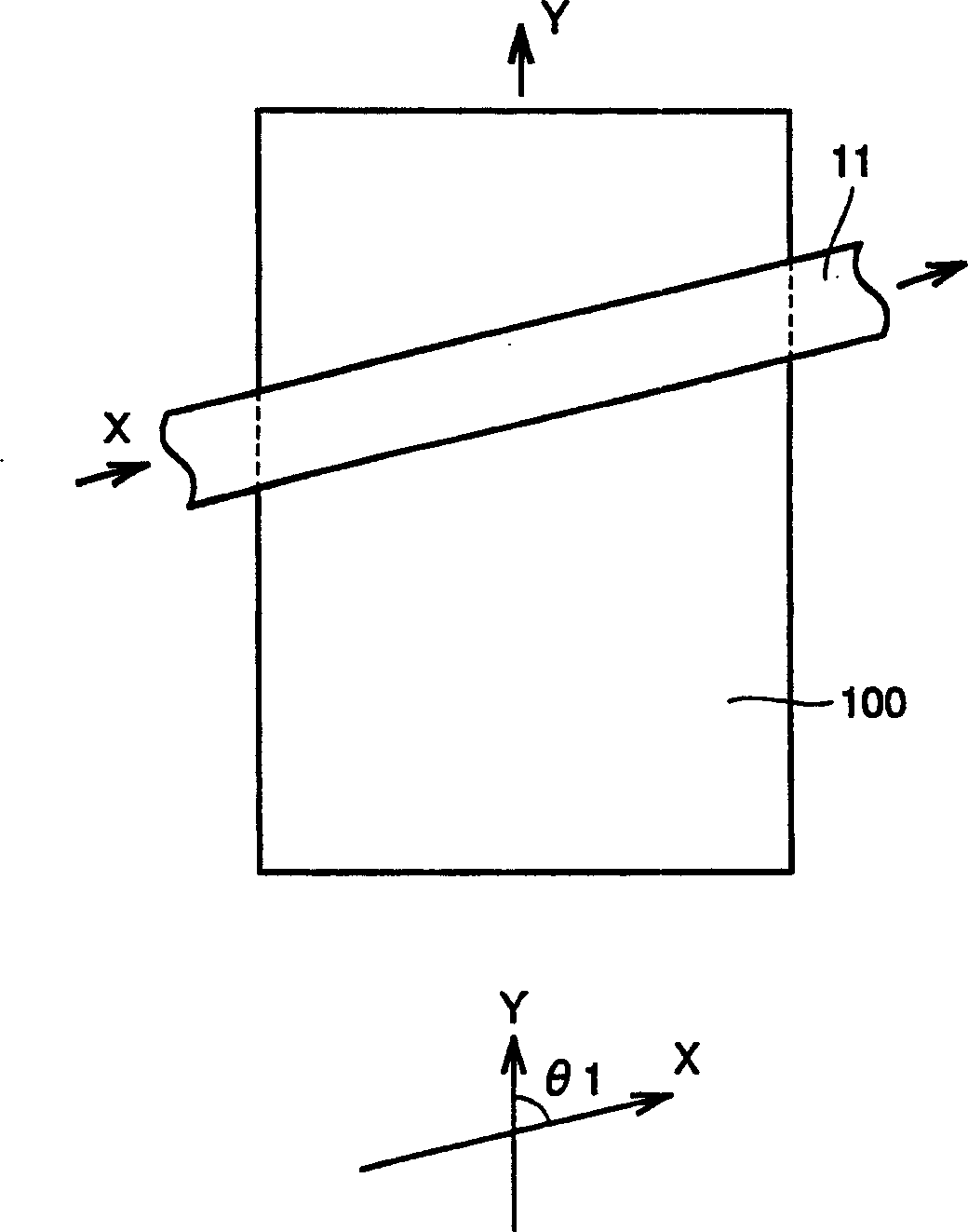

[0022] Below, refer to Figure 1~3 A substrate surface cleaning device according to an embodiment of the present invention will be described. In addition, in this embodiment, as an example, a case where the present invention is applied to a substrate surface cleaning device for performing a cleaning step in the manufacturing process of a liquid crystal panel will be described. Before the pasting process, clean the surface of the glass substrate that constitutes the liquid crystal panel. It should be noted that, figure 1 It is a schematic perspective view showing the basic configuration (schematic) of 100A of substrate support transfer apparatuses according to this embodiment, figure 2 It is a schematic front view showing the basic configuration (schematic) of 100A of substrate support transfer apparatuses according to this embodiment, image 3 It is a schematic plan view showing the relationship between the liquid crystal panel conveyance direction and the cleaning belt sl...

Embodiment

[0029] Next, refer to Figure 4 and Figure 5 The structure of the above-mentioned substrate surface cleaning apparatus 1000 as a specific example of the structure provided with the above-mentioned substrate surface cleaning apparatus 100A will be described. also, Figure 4 is a front view of the substrate surface cleaning device 1000, Figure 5 It is a plan view of the substrate surface cleaning device 1000 .

[0030] refer to Figure 4 and Figure 5 This substrate surface cleaning apparatus 1000 has a main body frame 1001 and side frames 1002 disposed above the main body frame 1001 and facing each other with a predetermined interval therebetween. A substrate cleaning device 1010 and a substrate supporting transfer device 1020 are provided between the side frames 1002 .

[0031]As the substrate supporting transport device 1020, a plurality of input rotary rollers 1021 and output rotary rollers 1022 are arranged side by side. A pulley 1040 for transmitting the rotation ...

Embodiment approach 2

[0041] In the substrate surface cleaning apparatus 100A according to Embodiment 1 described above, a case where one set of substrate cleaning apparatuses 10 are installed above the center portion of the substrate supporting transport apparatus 20 has been described. Therefore, in order to clean both sides of the liquid crystal panel 50, after one side is treated, the liquid crystal panel must be turned over and then the other side is cleaned. Therefore, in the substrate surface cleaning device of this embodiment, a configuration is adopted in which two sets of substrate cleaning devices are installed with the substrates to be transported sandwiched between them. As for the device, the second substrate cleaning device is placed under the substantially central part of the substrate support transfer device.

[0042] Below, refer to Image 6 and Figure 7 , the configuration of the substrate surface cleaning apparatus 100B of this embodiment will be described. and also, Image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com