Steel plate-concrete flitch plate

A technology of concrete and composite slabs, applied in bridge parts, building materials, bridges, etc., can solve the problems of difficult and effective realization of design and construction, and achieve the effects of being conducive to controlling concrete cracking, having good environmental effects and reducing the self-weight of the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

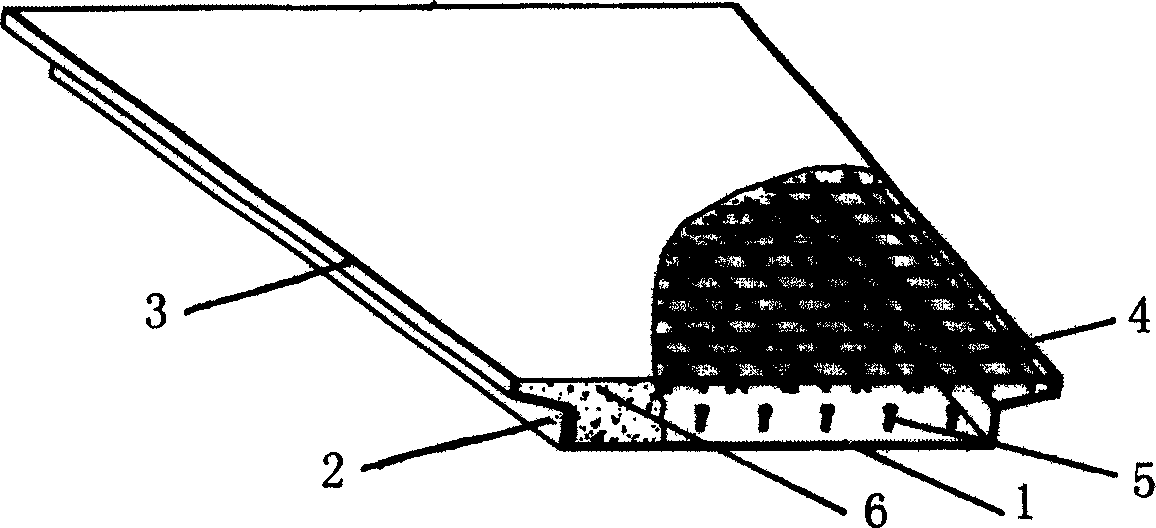

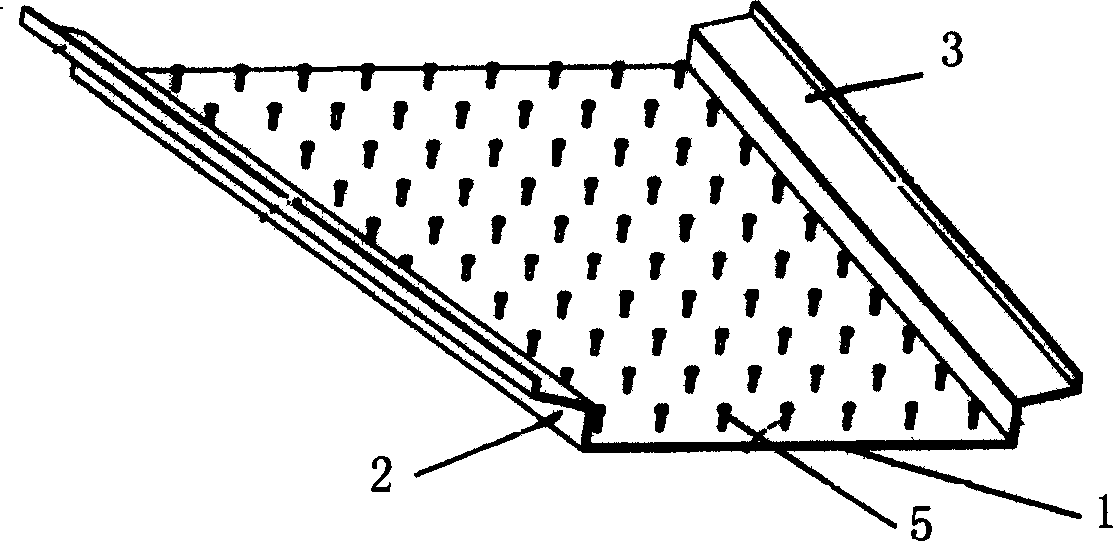

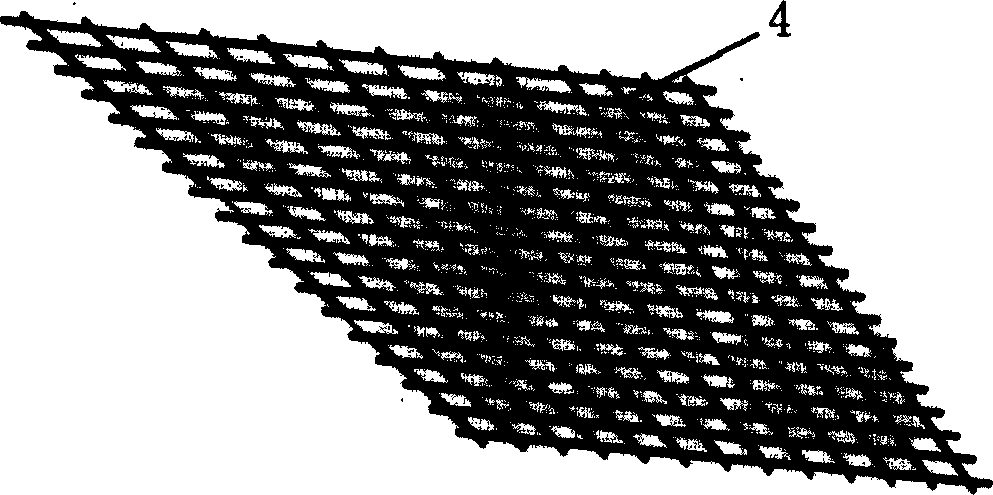

[0014] The invention provides a steel plate-concrete composite plate which can significantly improve its bearing capacity, rigidity and crack resistance. exist figure 1 , figure 2 and image 3 In the schematic diagram of the steel plate-concrete composite plate structure shown, the shear connector stud 5 is welded on the prefabricated steel plate 1, the steel mesh 4 is set on the upper part of the stud 5, and the concrete 6 is poured on both sides of the steel plate 1 to block Between the plates 2, the pegs 5 and the steel mesh 4 are wrapped, and are combined with the steel plate 1, and the surface is flush with the upper edge of the upper wing plate 3 of the steel plate 1.

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] Construction process of the present invention is:

[0017] The steel plate-concrete composite plate structure of the present invention is composed of two pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com