Surface light source device

A surface light source and light source technology, applied in the direction of light source, identification device, point light source, etc., can solve the problems of uneven brightness of surface light source device 1, low brightness of surface light source device 1, and poor combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

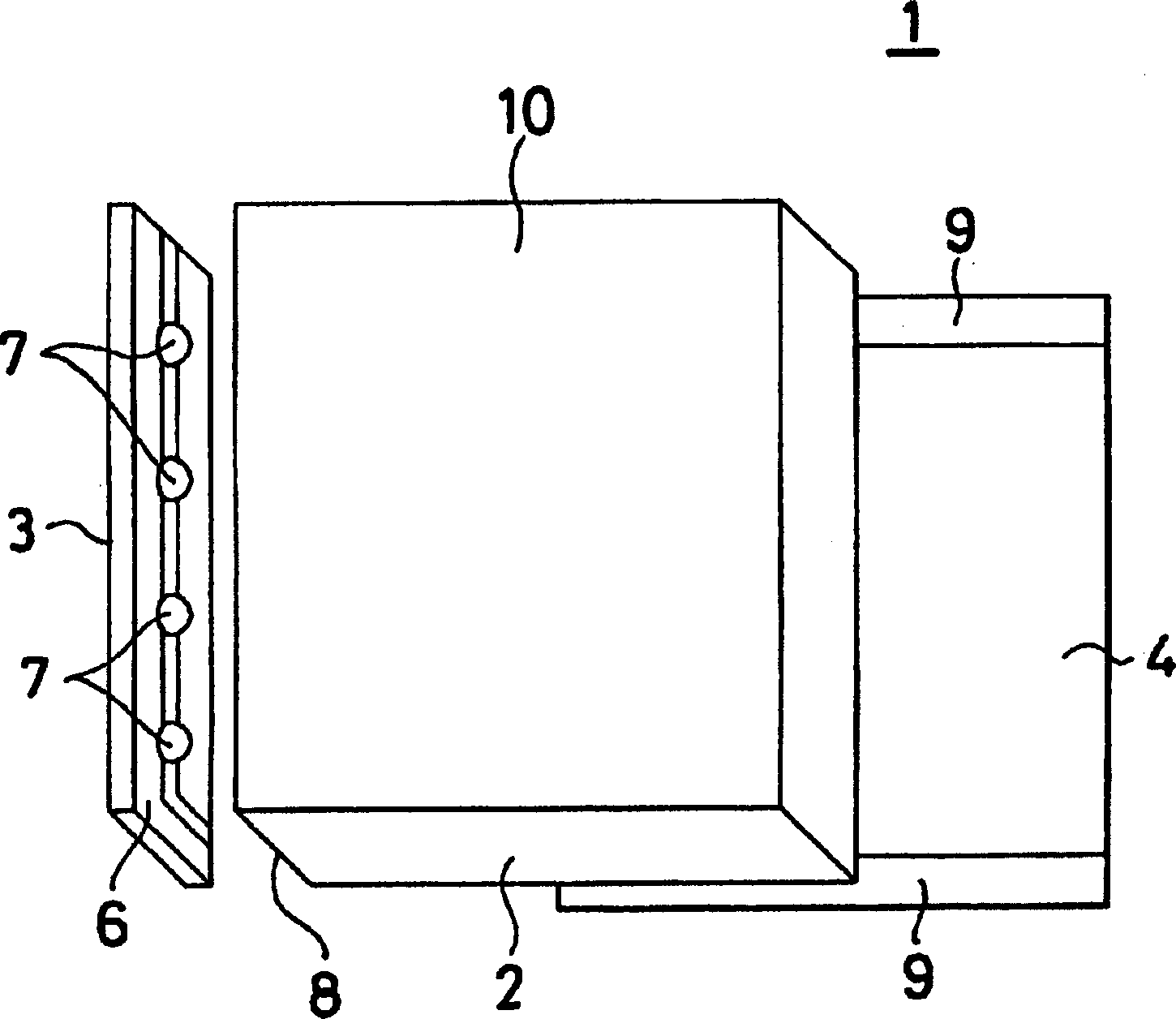

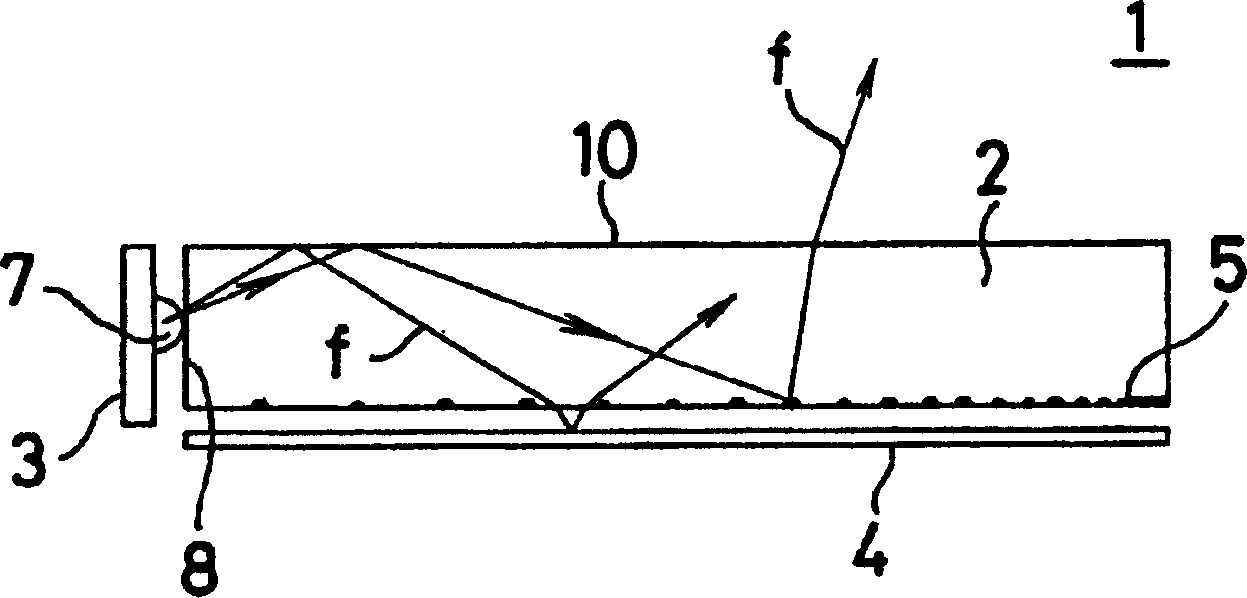

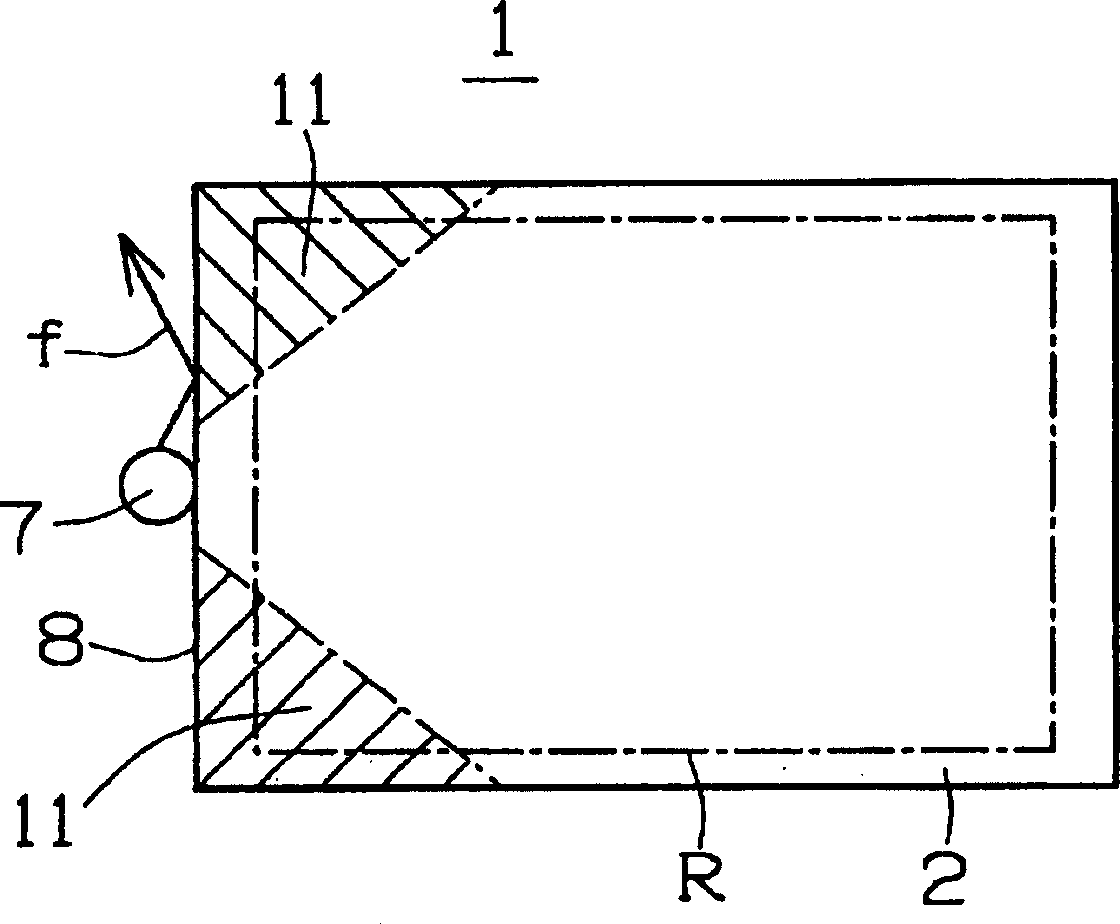

[0039] Figure 4 It is a perspective view showing the surface light source device 21 of Embodiment 1 of the present invention, Figure 5 It is a longitudinal section view of its partial section. In this surface light source device 21, a light emitting surface 23 is formed on the upper surface of a light guide plate 22 formed of a transparent resin material with a large refractive index, and a diffusion pattern (not shown) formed by concave-convex processing and dot printing of diffuse reflection ink is formed on the lower surface. ). A reflective plate 24 is arranged under the light guide plate 22, which is made of a material with high surface reflectivity, such as a hard or relatively soft white plastic plate. The central rectangular area of the light exit surface 23 is the effective area R. As shown in FIG. The effective region R is a region facing the region where the pixels of the liquid crystal display are formed, for example, when used as a surface light source devi...

Embodiment 2

[0044] Figure 7 It is a perspective view showing the surface light source device 41 of Embodiment 2 of the present invention, Figure 8 It is a longitudinal section view of its partial section. The hollow portion 42 of the surface light source device 41 is cylindrical and passes through the light guide plate 22 . As shown in the present embodiment and the following embodiments, the shape of the space 42 is not particularly limited, and the influence of the shape on the luminance distribution is different.

[0045] Such as Figure 8 As shown, the light emitted from the light emitting portion 26 is the same as in the first embodiment, and the light efficiently combined with the light guide plate 22 and reaching the void 42 is reflected in the general surface direction of the light guide plate 22 and diffused throughout the light guide plate 22 . At this time, the light is totally reflected backward on the boundary surface between the light guide plate 22 and the space 42, so...

Embodiment 3

[0047] Figure 9 It is a perspective view showing a surface light source device 43 according to Embodiment 3 of the present invention, Figure 10 It is the longitudinal sectional view of the same partial section as above. The hollow part 44 of the surface light source device 43 does not penetrate the light guide plate 22 , that is, it is a cylinder that does not reach the light emitting surface 23 in the second embodiment. In this way, as long as the space 44 is a structure that does not reach the light exit surface 23, the leakage of the light f from the space 44 in the thickness direction of the light guide plate 22 can be reduced ( Figure 10 shown by the dotted line in the middle), to prevent the reduction of the uniformity of the brightness distribution.

[0048] Such as Figure 10 As shown, the light emitted from the light emitting portion 26 is the same as in the first embodiment, and the light efficiently combined with the light guide plate 22 and reaching the void ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com