Dual-active blade type secondry component

A secondary element and blade type technology, applied in the field of double-acting blade type secondary elements, can solve the problems of limited application range of secondary elements, large flow range, complex structure of secondary elements, etc., to enrich the variety and expand the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

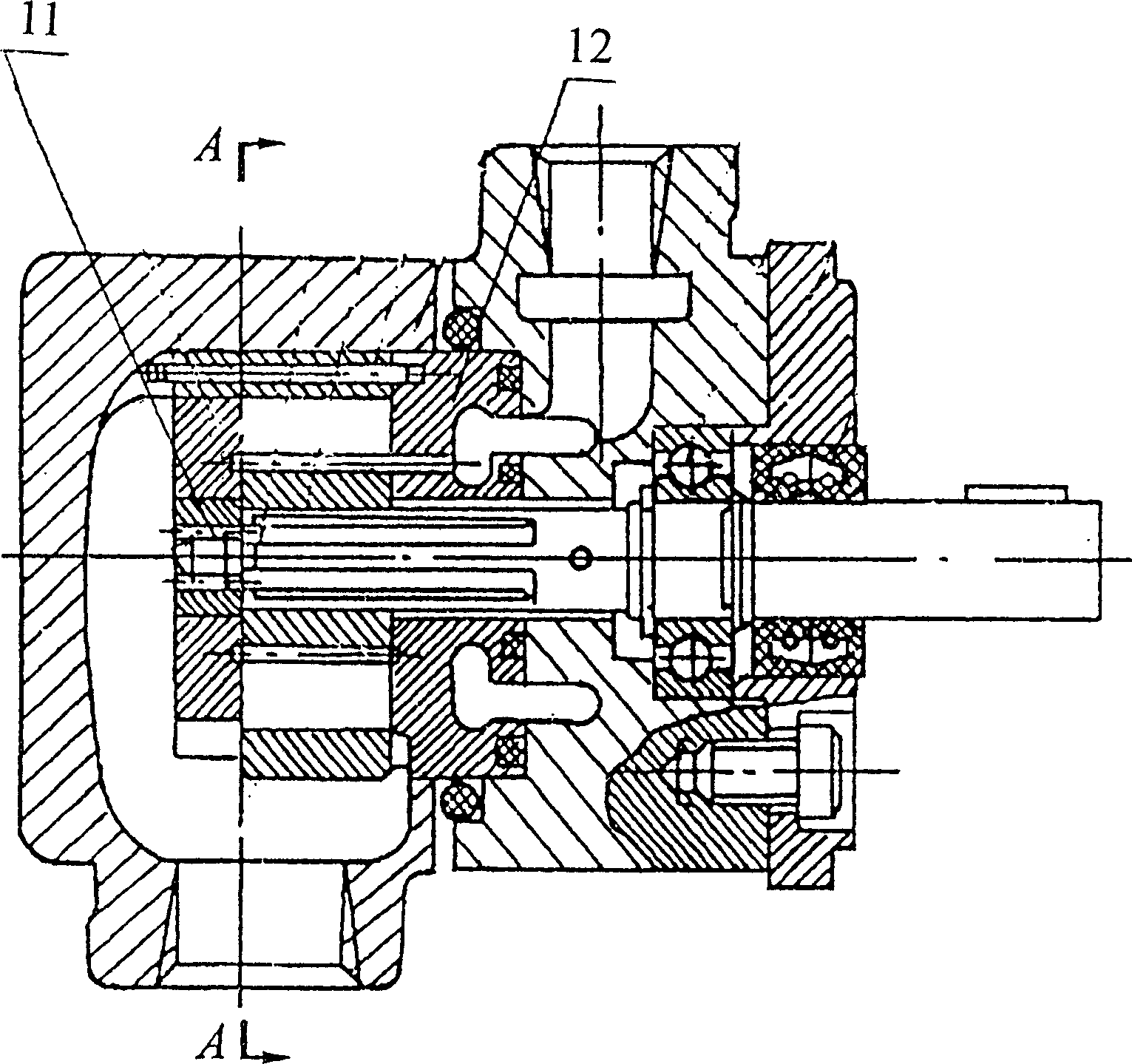

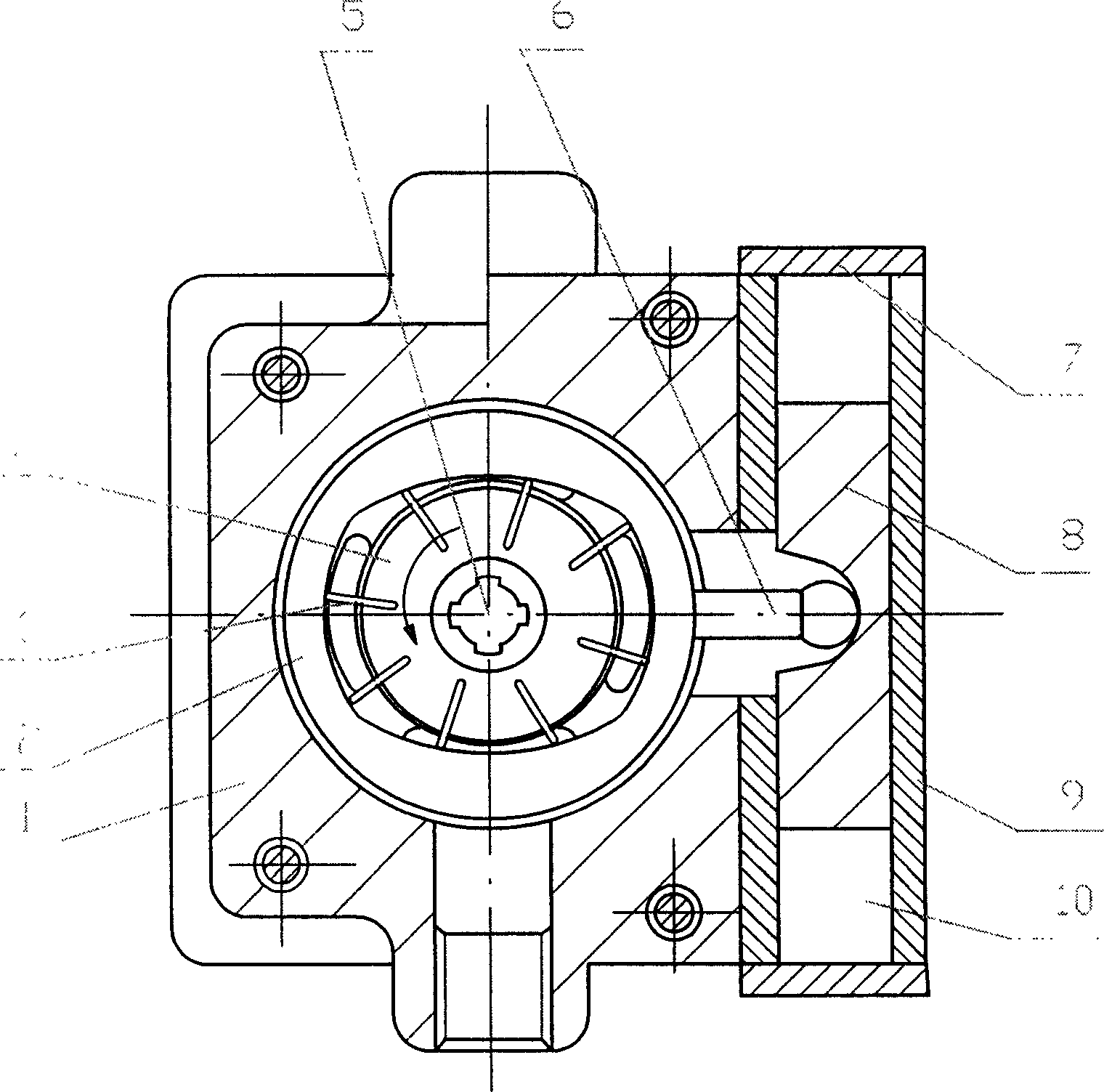

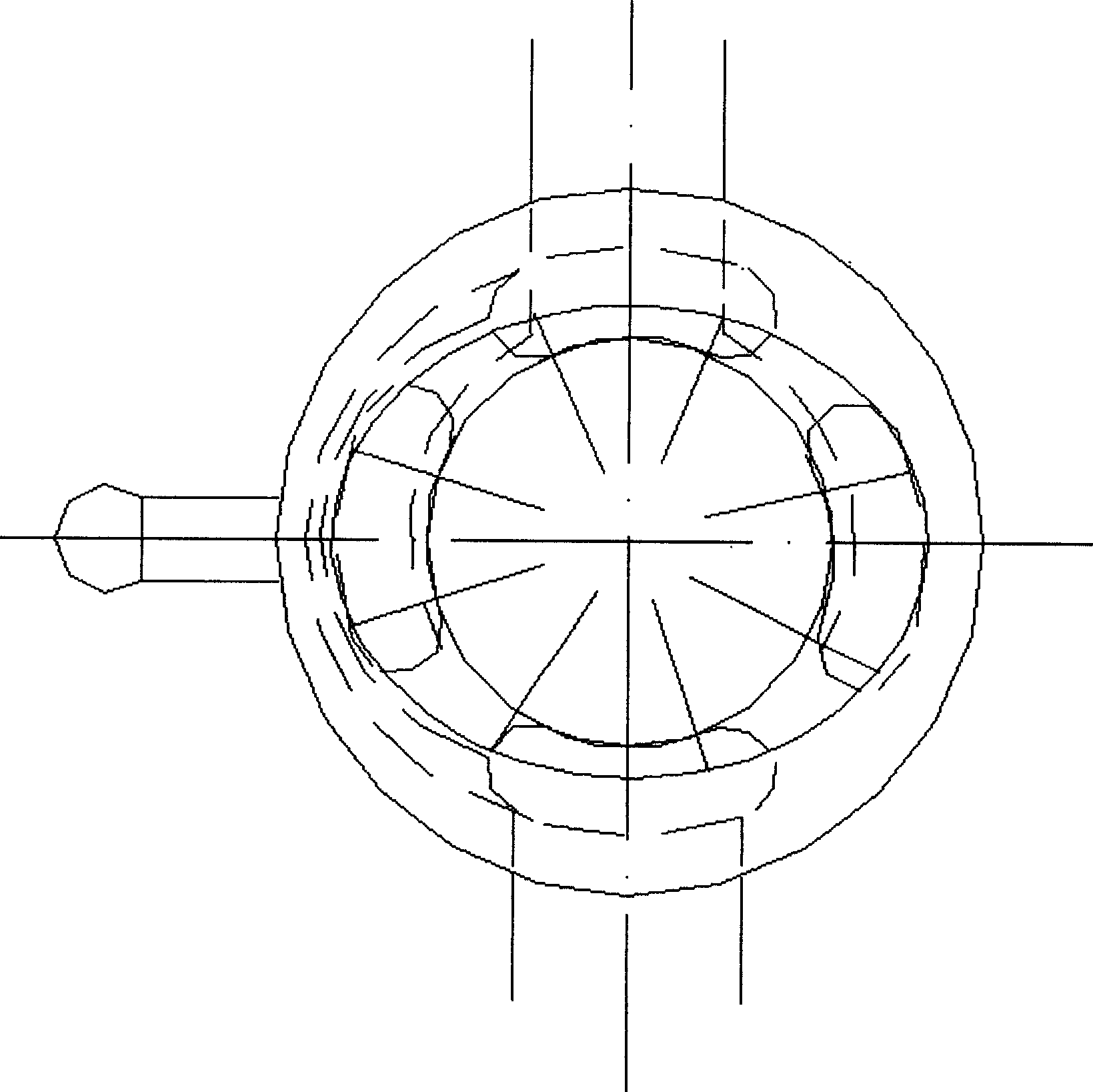

[0013] A double-acting vane-type secondary element is mainly composed of a rotor 4, a stator 2, a vane 3, a variable oil cylinder 10, a housing 1, and flow distribution plates 11 and 12. The variable oil cylinder 10 is composed of a variable rod 6, a variable piston 8, a variable cylinder 9 and the like. The variable cylinder 9 is fixed on the housing 1 by bolts, the spherical head end of the variable rod 6 is connected with the groove of the variable piston 8, and the other end of the variable rod 6 is fixed on the center line of the long radius arc or the short radius of the stator 2. at the centerline of the arc, figure 2 In the illustrated embodiment of the present invention, the other end of the variable rod 6 is fixed on the outer surface of the stator 2 at the centerline of the long-radius arc.

[0014] The oil inlet and outlet of the secondary element are of the same size, the vanes 3 are arranged radially along the rotor 4 (that is, the placement angle is zero), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com