Heat pump set using sea water source

A source heat pump and unit technology, applied in the field of seawater source heat pump units, can solve the problems of increasing prices, decreasing unit operating efficiency, increasing production costs, etc., and achieving the effects of reducing heat transfer temperature difference, reducing production costs, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

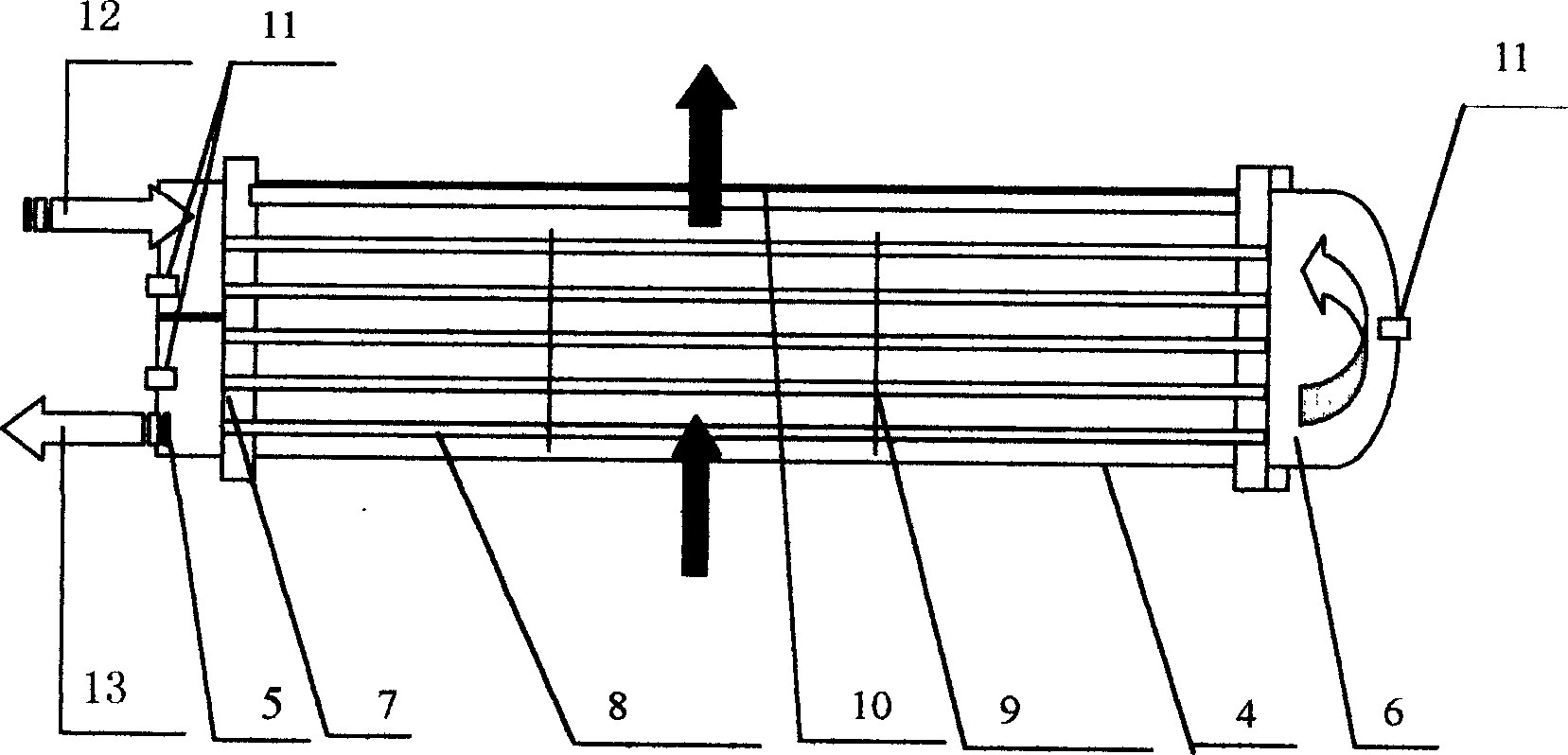

[0019] see figure 2 The cylinder body 4 of the flooded evaporator 1 can be made of ordinary steel plate or seamless steel pipe material, and several corrosion-resistant heat exchange tubes 8 are installed in the cylinder body 4, and the corrosion-resistant heat exchange tubes 8 can be made of white copper (BFe30-1- 1 or BFe10-1-1 material), fixedly install the corrosion-resistant tube sheet 7 with holes at the end of the cylinder 4, the corrosion-resistant tube sheet 7 can be made of aluminum bronze or aluminum brass, and the corrosion-resistant heat exchange tube 8 is fixed in the hole of the corrosion-resistant tube plate 7, and several support plates 9 can also be erected in the cylinder body 4 to stabilize the corrosion-resistant heat exchange tube 8. One end of the cylinder body 4 is connected to the water tank 5, and the water tank 5 is separated into Two parts (two water tanks can also be arranged side by side), with water inlet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com