Apparatus for measuring ultra narrow laser line width by Brillouin optical fibre ring laser and measuring method

A ring laser and laser line width technology, applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problems of low measurement accuracy and complex devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

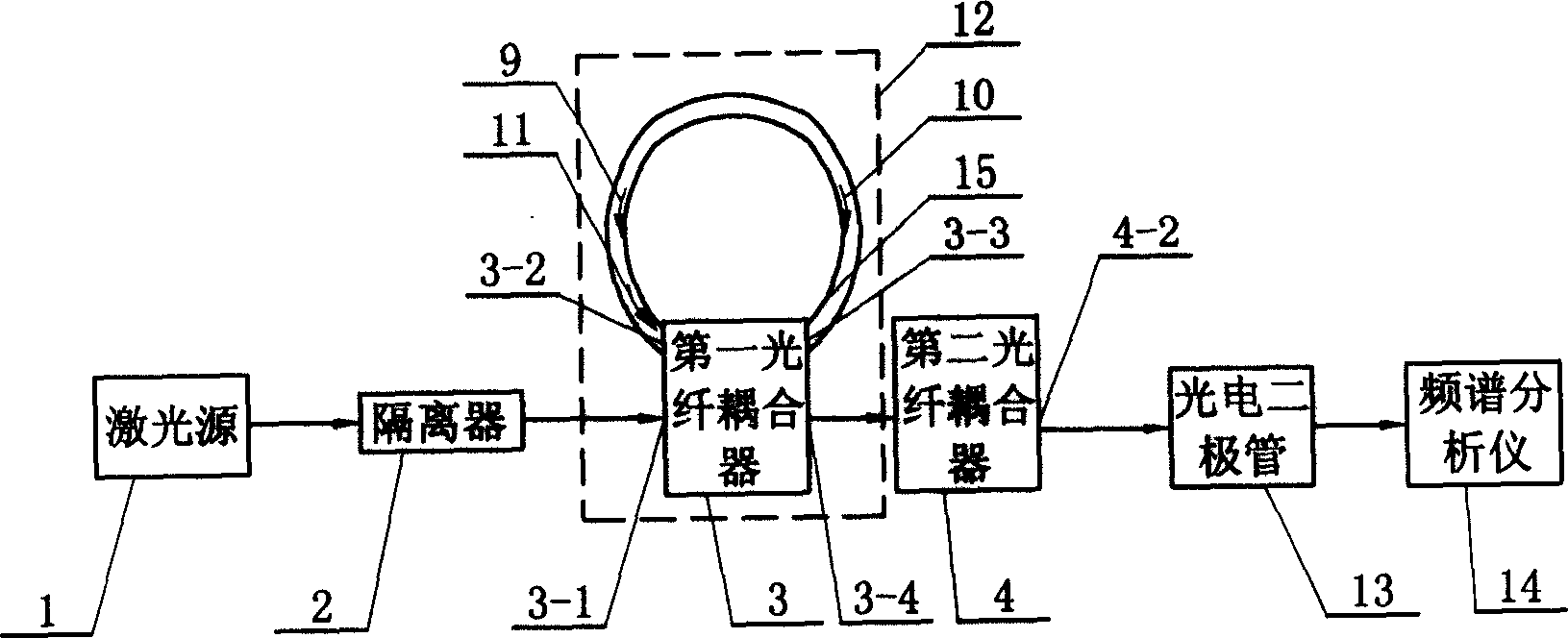

[0005] Specific implementation mode one: this implementation mode refers to figure 1 , which consists of a Brillouin fiber ring laser, a second fiber coupler 4, a photodiode 13, and a spectrum analyzer 14. The Brillouin fiber ring laser consists of a laser source 1, an isolator 2, and a fiber ring cavity 12. Optical fiber ring cavity 12 is made up of single-mode fiber, the first fiber coupler 3, and one end of the split ring 15 that is made of single-mode fiber is connected with the optical transmission port 3-2 of the first fiber coupler 3, and the other end of split ring 15 It is connected with the optical transmission port 3-3 of the first optical fiber coupler 3. The coupling ratio of the first fiber coupler 3 is 95:5˜98:2, and the coupling ratio of the second fiber coupler 4 is 55:45˜45:55. The output end of the laser source 1 is connected to the input end of the isolator 2 by an optical fiber, the output end of the isolator 2 is connected to the input end 3-1 of the fi...

specific Embodiment approach 2

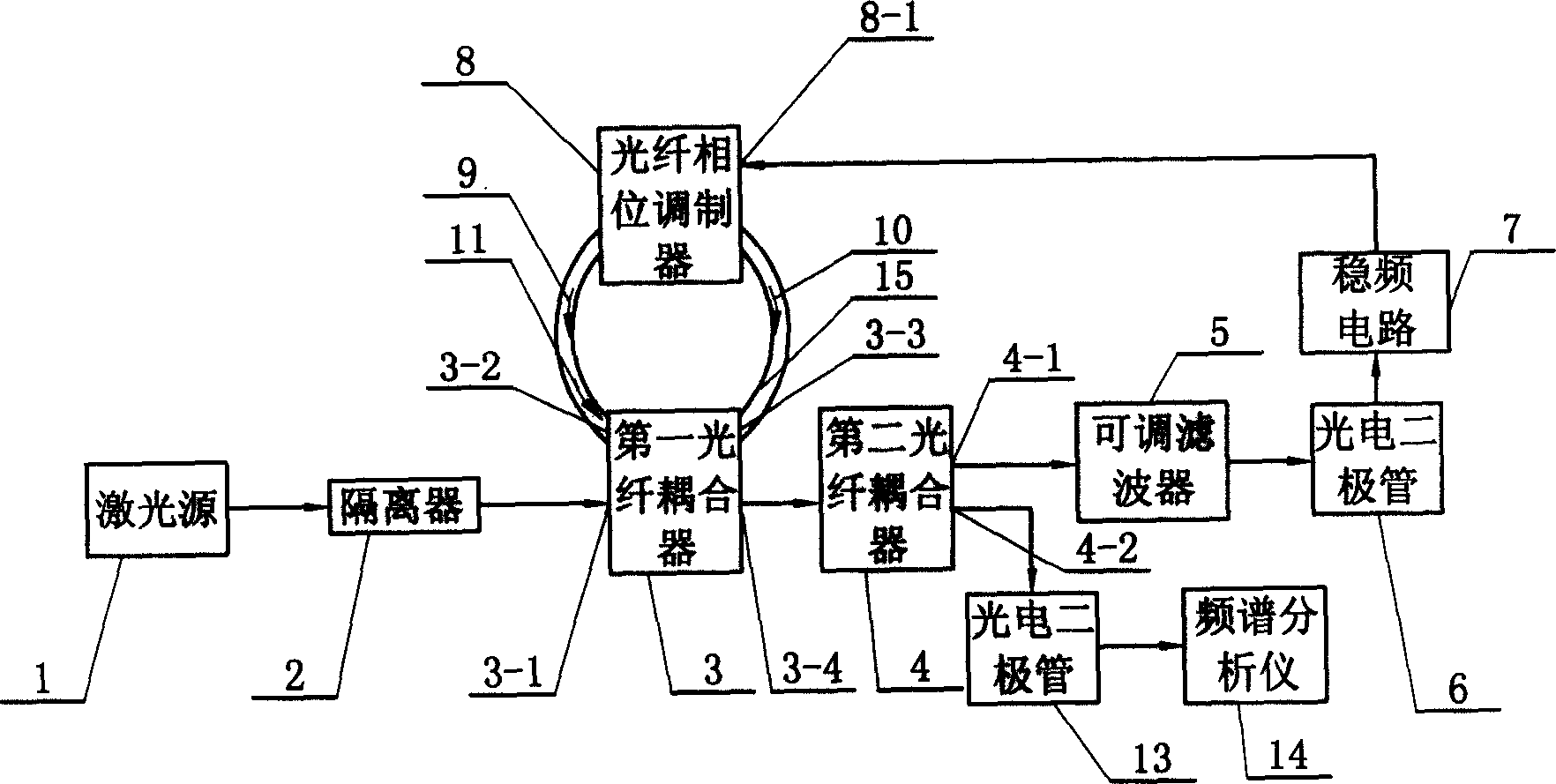

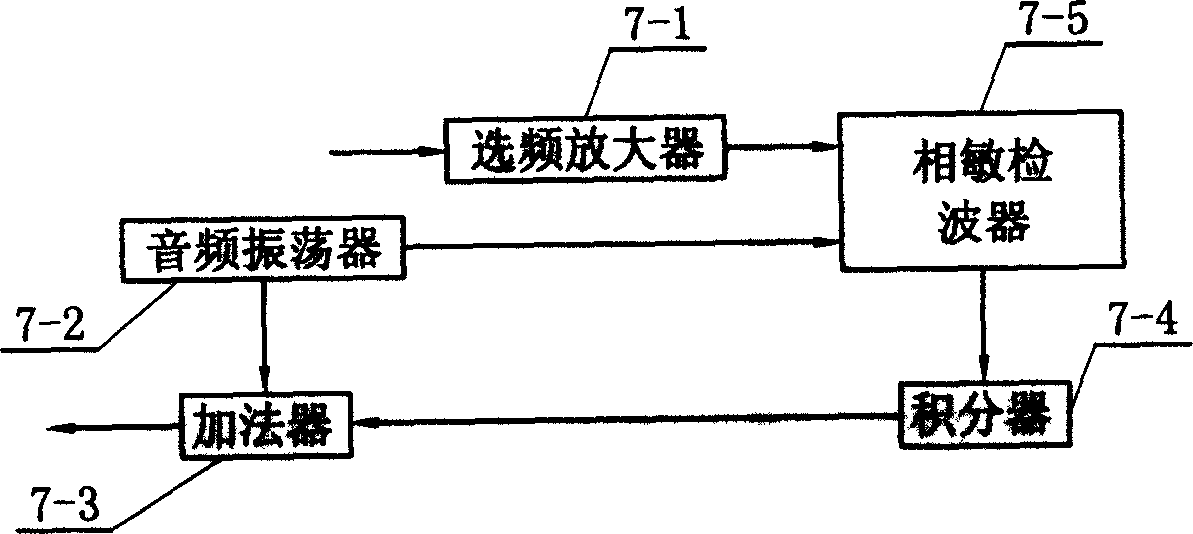

[0006] Specific implementation mode two: refer to figure 2 The difference between this embodiment and the first embodiment is that it also includes a tunable filter 5 , a photodiode 6 , a frequency stabilization circuit 7 , and an optical fiber phase modulator 8 . The second output end 4-1 of the second fiber coupler 4 is connected by an optical fiber with the input end of the tunable filter 5, and the output end of the tunable filter 5 is connected by an optical fiber with the input end of the photodiode 6, and the photodiode 6 The output end of the frequency stabilizing circuit 7 is connected by wires, and the output end of the frequency stabilizing circuit 7 is connected with the voltage input end 8-1 of the optical fiber phase modulator 8 by wires. The two optical transmission ports of the optical fiber phase modulator 8 are connected in series in a split ring 15 composed of a single-mode optical fiber, and are arranged symmetrically with the first optical fiber coupler 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com