Separater and measuring method for measuring water content of oil well

A measuring method and separator technology, which are applied to measuring devices, by removing certain components, weighing, instruments, etc., to achieve the effects of improving measuring accuracy, simple separator and measuring method, and simple measuring process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

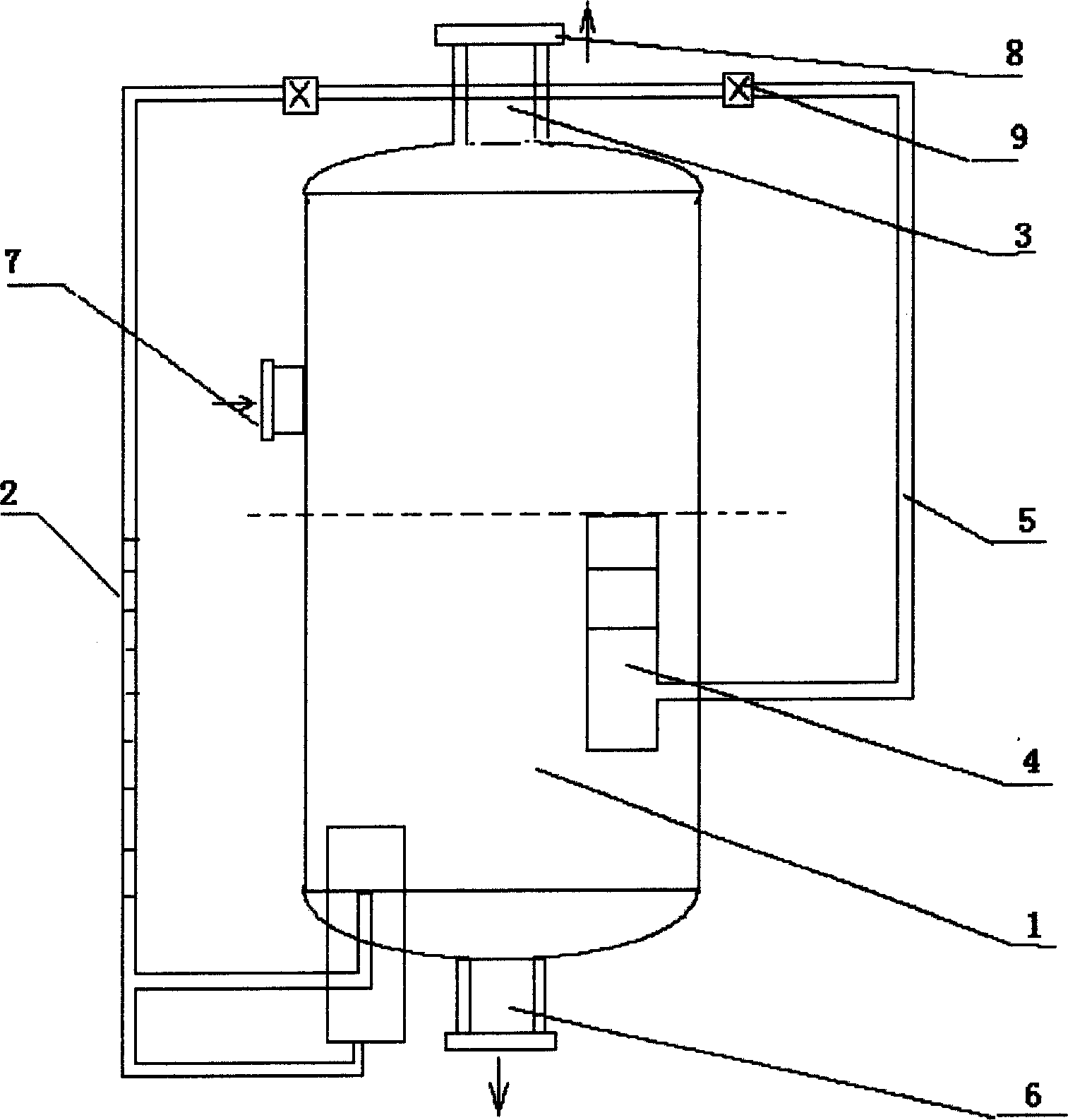

[0009] In an embodiment, with reference to the drawings, the separator includes a separator main body 1 , a first liquid level gauge 2 , an inlet 7 , an outlet 6 , an exhaust port 8 , and a gas balancer 3 . Open a hole at the upper scale of the first liquid level gauge 2 of the separator main body 1, and communicate with the water bag 4, install the second liquid level gauge 5 on the top surface of the water bag 4, and the exhaust port on the top of the separator main body 1 It communicates with the first liquid level gauge 2 and the second liquid level gauge 5 through the gas balancer 3 . Control valves 9 are respectively installed on the connecting pipes of the gas balancer 3 and the first liquid level gauge 2 and the second liquid level gauge 5 .

[0010] The separator in the present invention is based on the original 600mm separator used in the oil field, and is modified according to the principle of a connecting device: a hole is opened at a distance of 720mm from the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com