Electrooptical device, electronic device and manufacturing method of electrooptical device

An electro-optic device and manufacturing method technology, applied to identification devices, optics, nonlinear optics, etc., capable of solving problems such as floating from a liquid crystal display panel or light guide plate, LED luminance reduction, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Next, preferred embodiments of the present invention will be described with reference to the accompanying drawings. In addition, in the following description, a liquid crystal display device will be described as an example of the electro-optical device according to Embodiment 1 of the present invention.

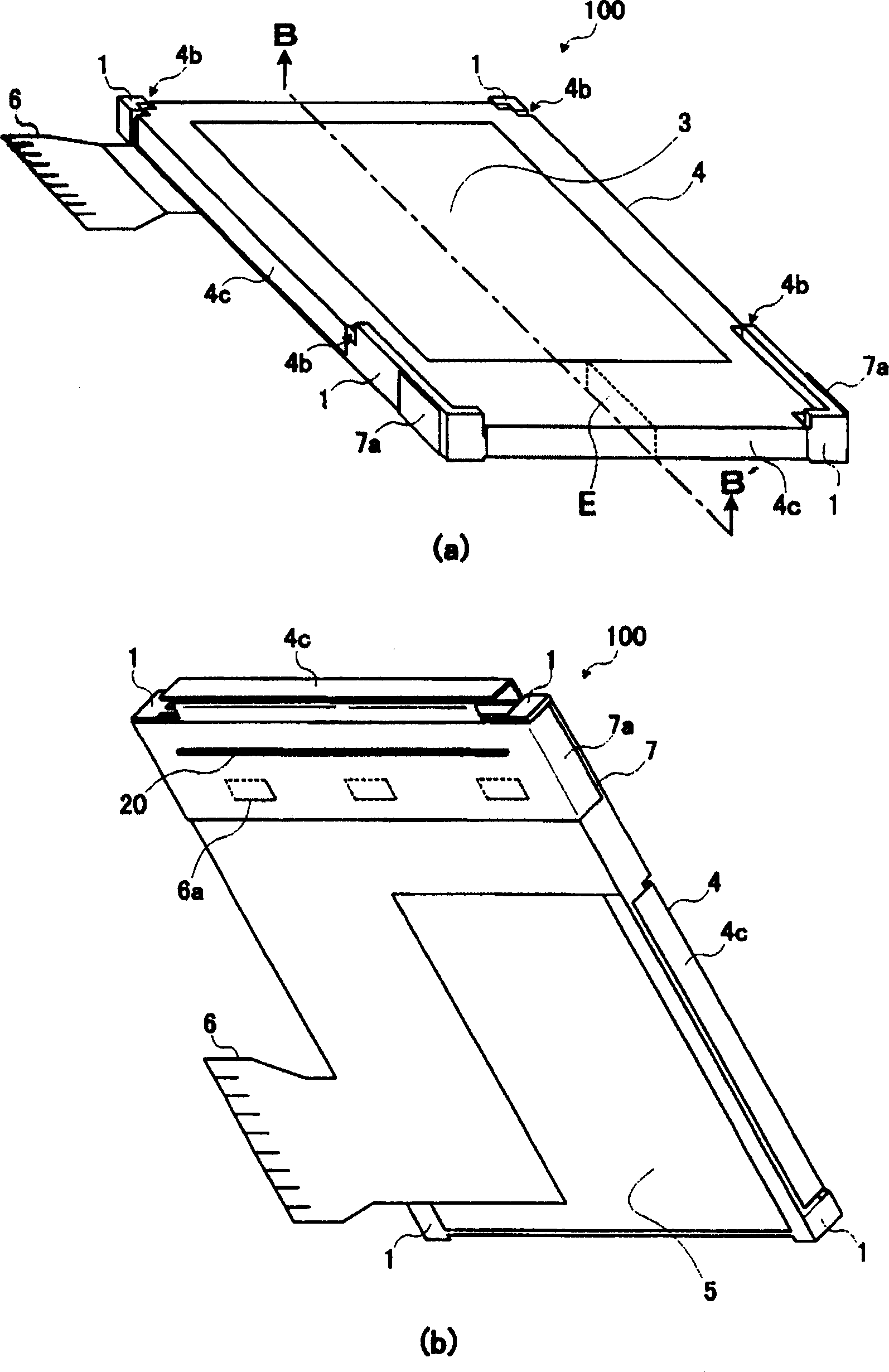

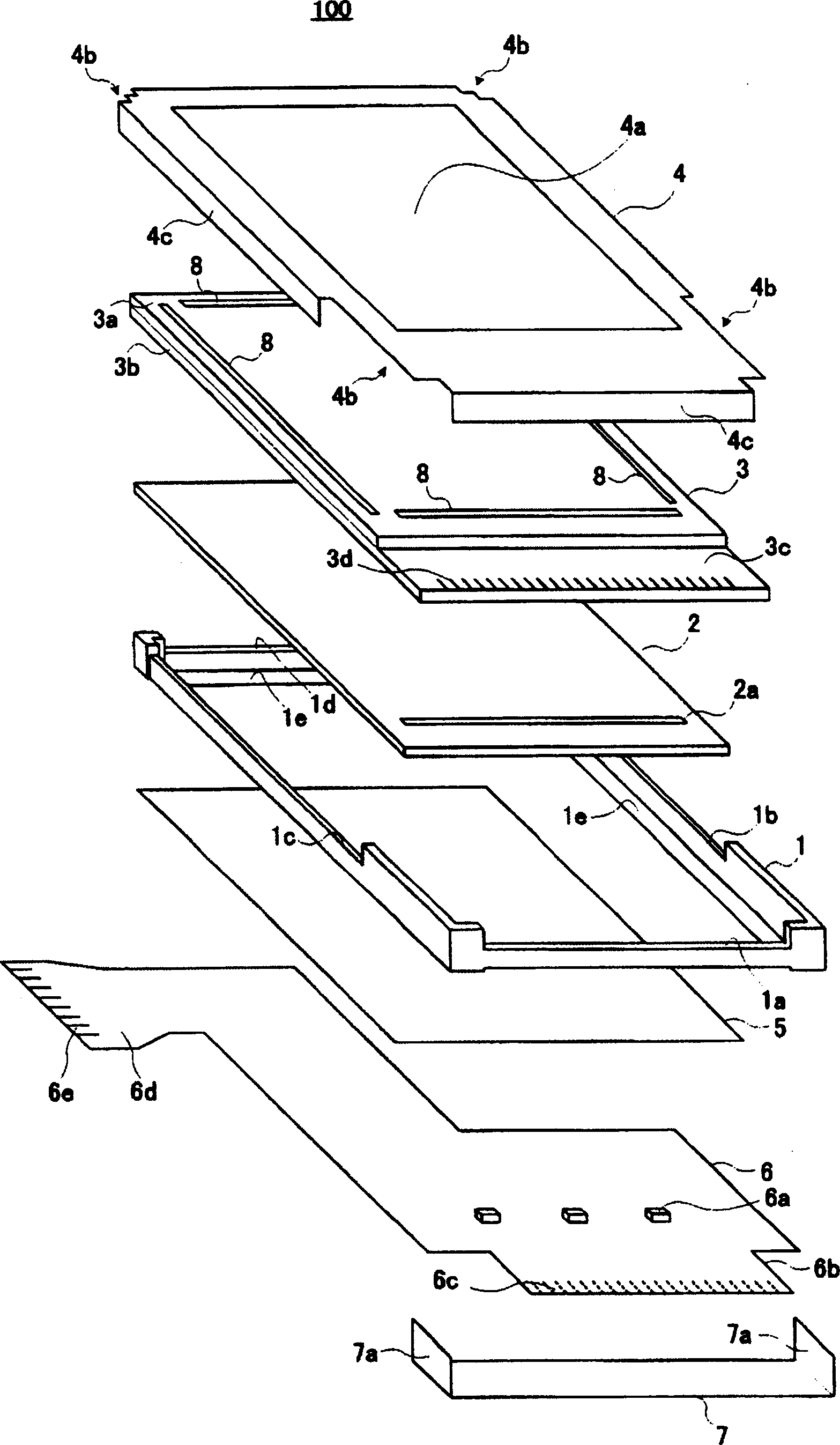

[0035] figure 1 It is a perspective view showing a schematic configuration of a liquid crystal display device according to Embodiment 1 of the present invention. figure 1 (a) shows the display part side (top side) of the liquid crystal display device 100, figure 1 (b) shows the back side. in addition, figure 2 express figure 1 An exploded perspective view of the liquid crystal display device 100 shown.

[0036] Such as figure 1 and figure 2 As shown, the liquid crystal display device 100 has, from figure 2 The upper frame 4, the liquid crystal display panel 3, the light guide plate 2, the middle frame 1, the reflection sheet 5, the FPC 6 and the lower frame 7 ...

Embodiment 2

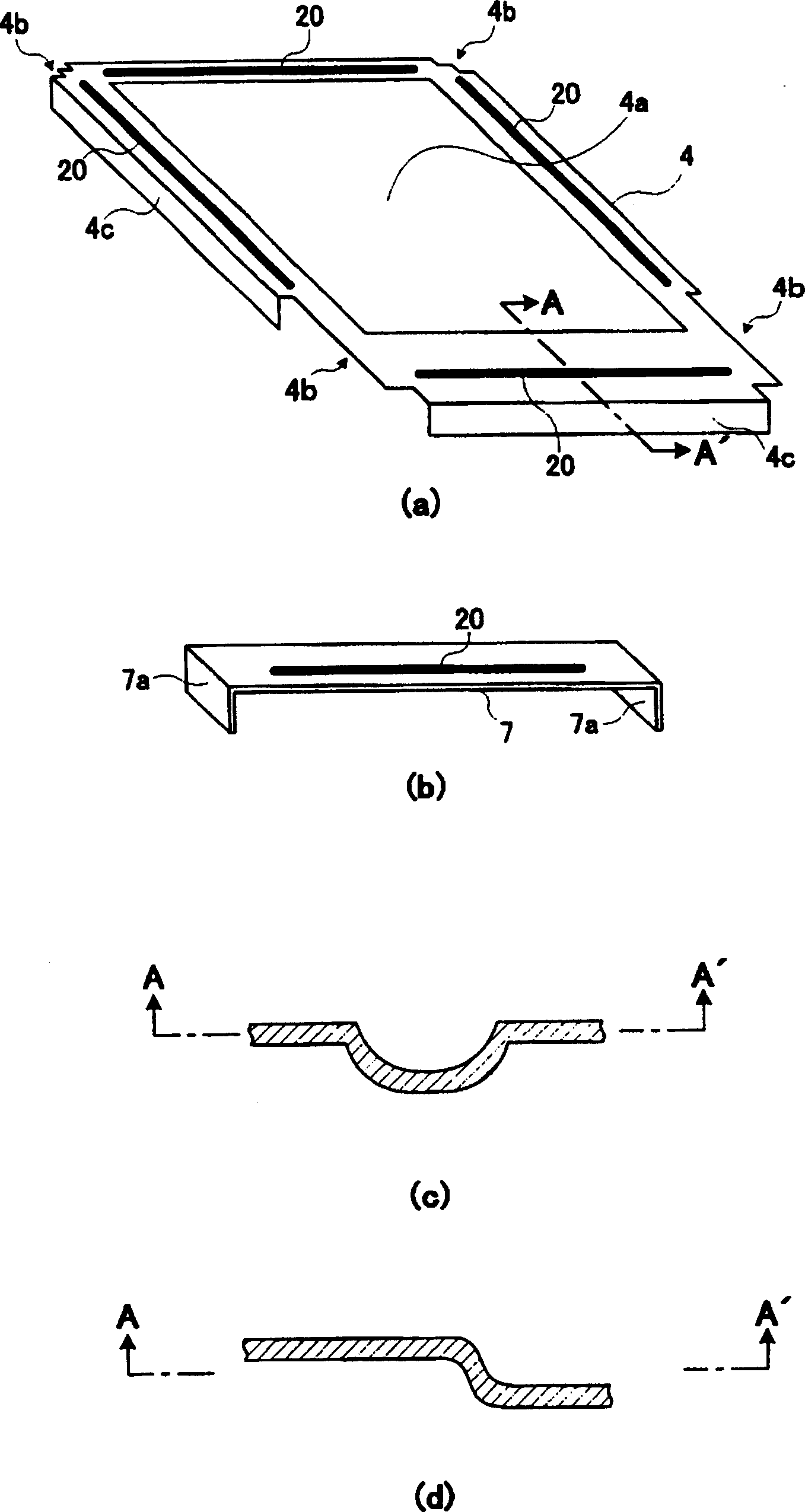

[0052] Next, the configuration and the like of the liquid crystal display device according to Embodiment 2 of the present invention will be described. In the following, the same components as those of the liquid crystal display device 100 of the first embodiment are denoted by the same reference numerals, and description thereof will be omitted.

[0053] Figure 5 It is a perspective view showing a schematic configuration of a liquid crystal display device 200 according to Embodiment 2 of the present invention. Figure 5 (a) shows the display part side (top side) of the liquid crystal display device 200, Figure 5 (b) shows the back side. Additionally, Figure 6 shows Figure 5 An exploded perspective view of the liquid crystal display device 200 shown.

[0054] Such as Figure 5 As shown in FIG. 6, the liquid crystal display device 200 of Embodiment 2 has an upper frame 4, a liquid crystal display panel 3, a light guide plate 2, a middle frame 1, a reflection sheet 5, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com