Luminous device

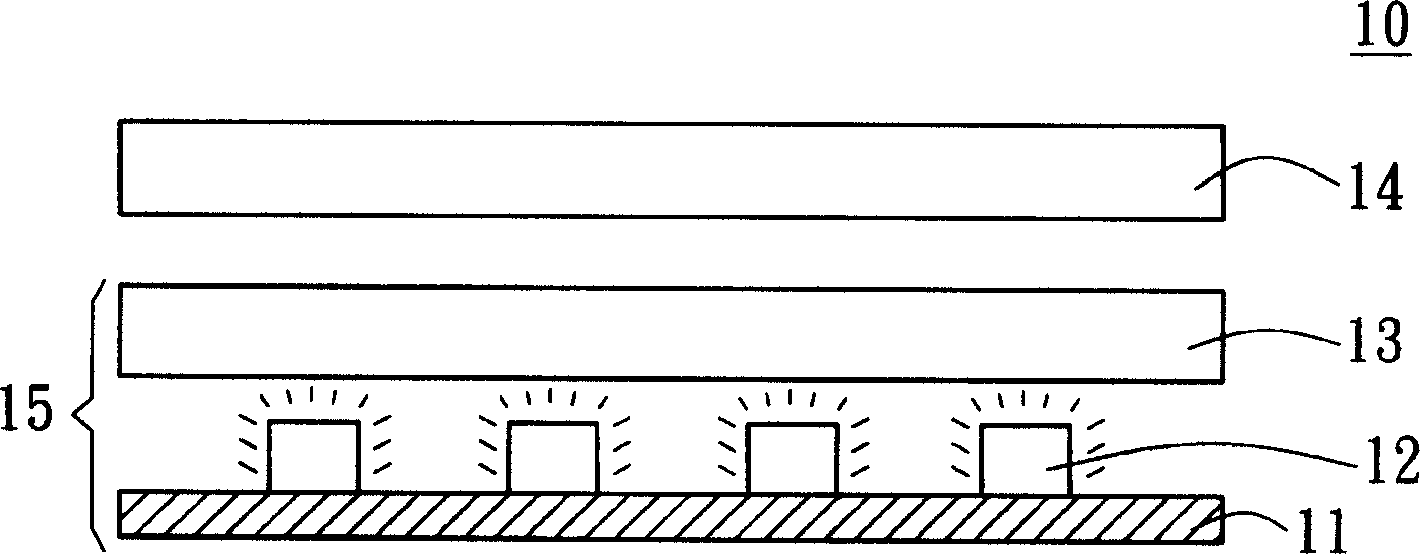

A light-emitting device and light-emitting diode technology, which is applied in the direction of lighting devices, optics, light sources, etc., can solve the problems of affecting the quality of light mixing and the deflection of the diffuser 13

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

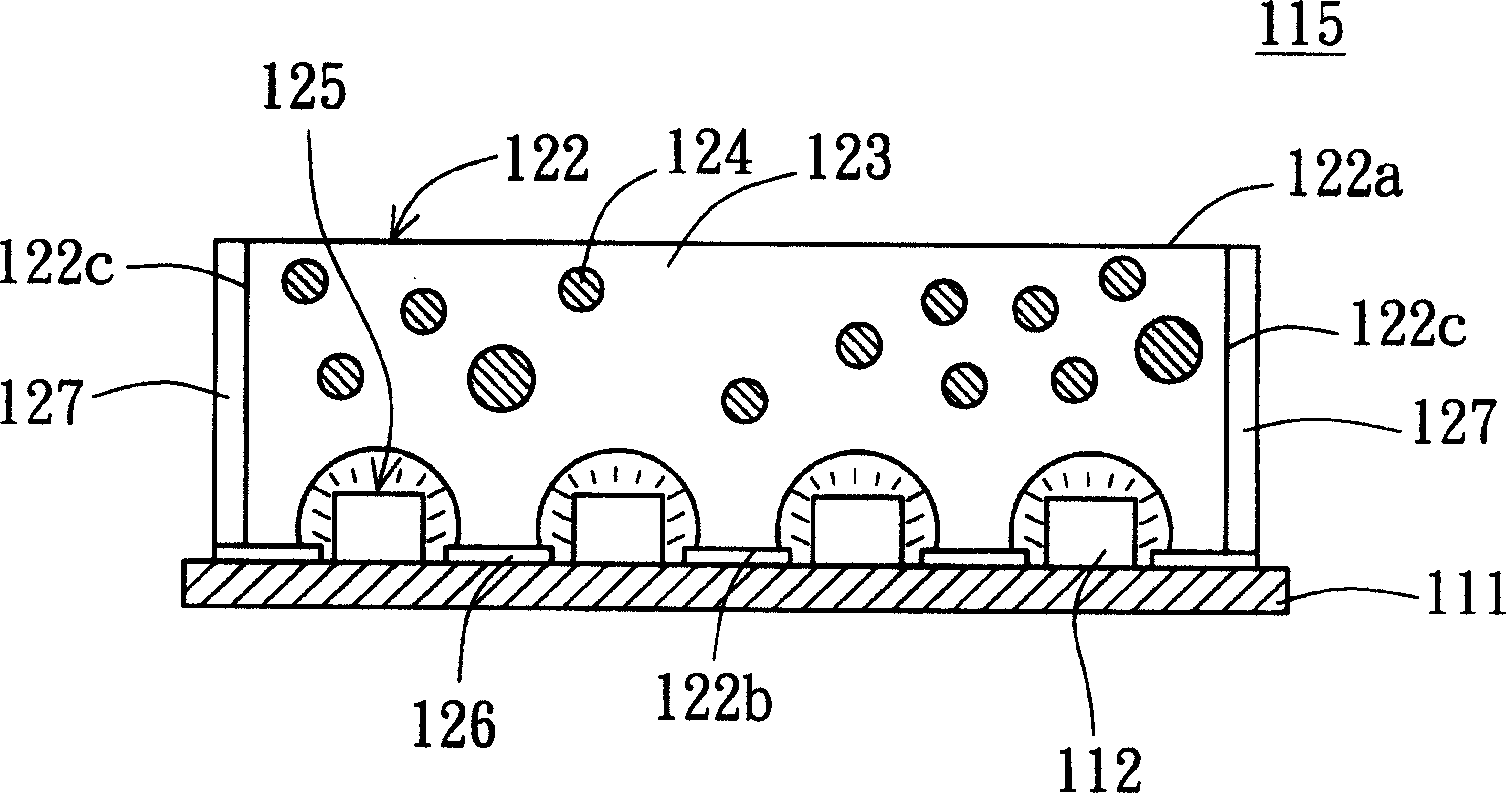

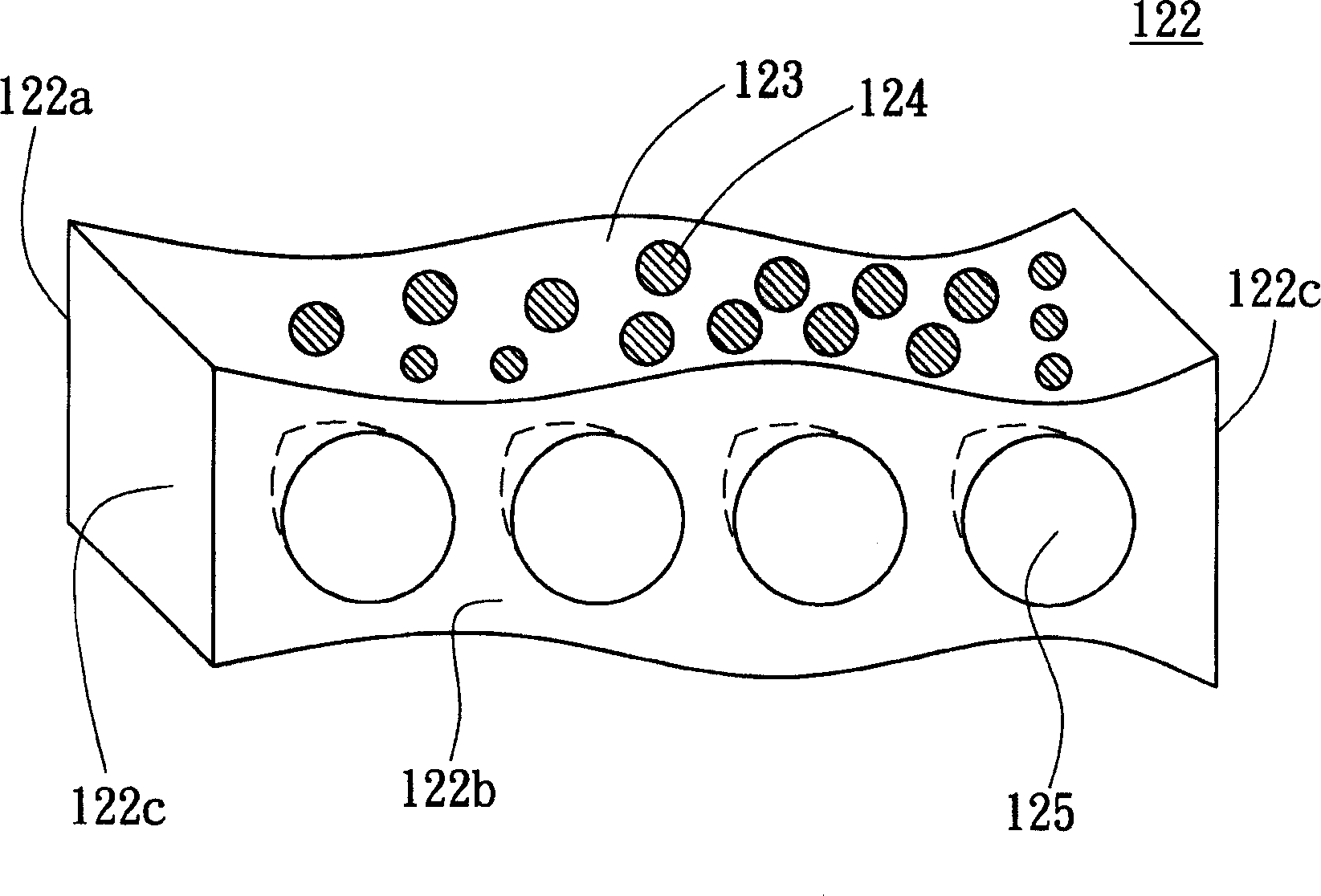

[0017] Please refer to figure 2 , which shows a cross-sectional view of the light emitting device according to Embodiment 1 of the present invention. exist figure 2 Among them, the light emitting device 115 at least includes a circuit board 111 , several light emitting diodes (LEDs) 112 , a first reflective material 126 , a diffusion structure 122 and several second reflective materials 127 . The LEDs 112 are disposed on the circuit board 111 and electrically connected to the circuit board 111 to provide light sources. For example, the LEDs 112 are composed of several red (R), green (G) and blue (B) LEDs.

[0018] The first reflective material 126 is disposed on the circuit board 112 , and the first reflective material 126 forms a plurality of through holes for the light-emitting surface of the LED 112 to protrude from the first reflective material 126 . After the first reflective material 126 is formed on the surface of the circuit board 111 by coating, the LED 112 can b...

Embodiment 2

[0024] Please refer to Figure 4 , shown in the figure is a cross-sectional view of a light emitting device according to Embodiment 2 of the present invention. The light emitting device 415 of this embodiment is different from the light emitting device 115 of Embodiment 1 in that the cross-sectional shape of the notch 425 of the light emitting device 415 is like an inverted end pyramid prism or pyramid shape, and other structures are similar to figure 2 The structure of the light emitting device 115 is the same, and will not be repeated here.

Embodiment 3

[0026] Please refer to Figure 5 , shown in the figure is a cross-sectional view of a light emitting device according to Embodiment 3 of the present invention. The difference between the light emitting device 515 of this embodiment and the light emitting device 115 of Embodiment 1 is that the cross-sectional shape of the notch 525 of the light emitting device 515 is like an inverted ellipse or ellipse at the end, and other structures are similar to figure 2 The structure of the light emitting device 115 is the same, and will not be repeated here.

[0027] The light emitting device disclosed in the above embodiments of the present invention has the following advantages:

[0028] 1. The design of its diffusion structure can increase the diffusion angle of LEDs with different luminous colors to achieve a more uniform light mixing effect.

[0029]2. Its diffusion structure can be in partial contact with the circuit board, which can avoid the bending phenomenon of the diffusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com