Discrete variable frequency starting system of AC induction motor and starting method

An induction motor and discrete frequency conversion technology, which is applied to the starter of a single multi-phase induction motor, motor generator/starter, etc., can solve the problem that the three-phase AC induction motor cannot start normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

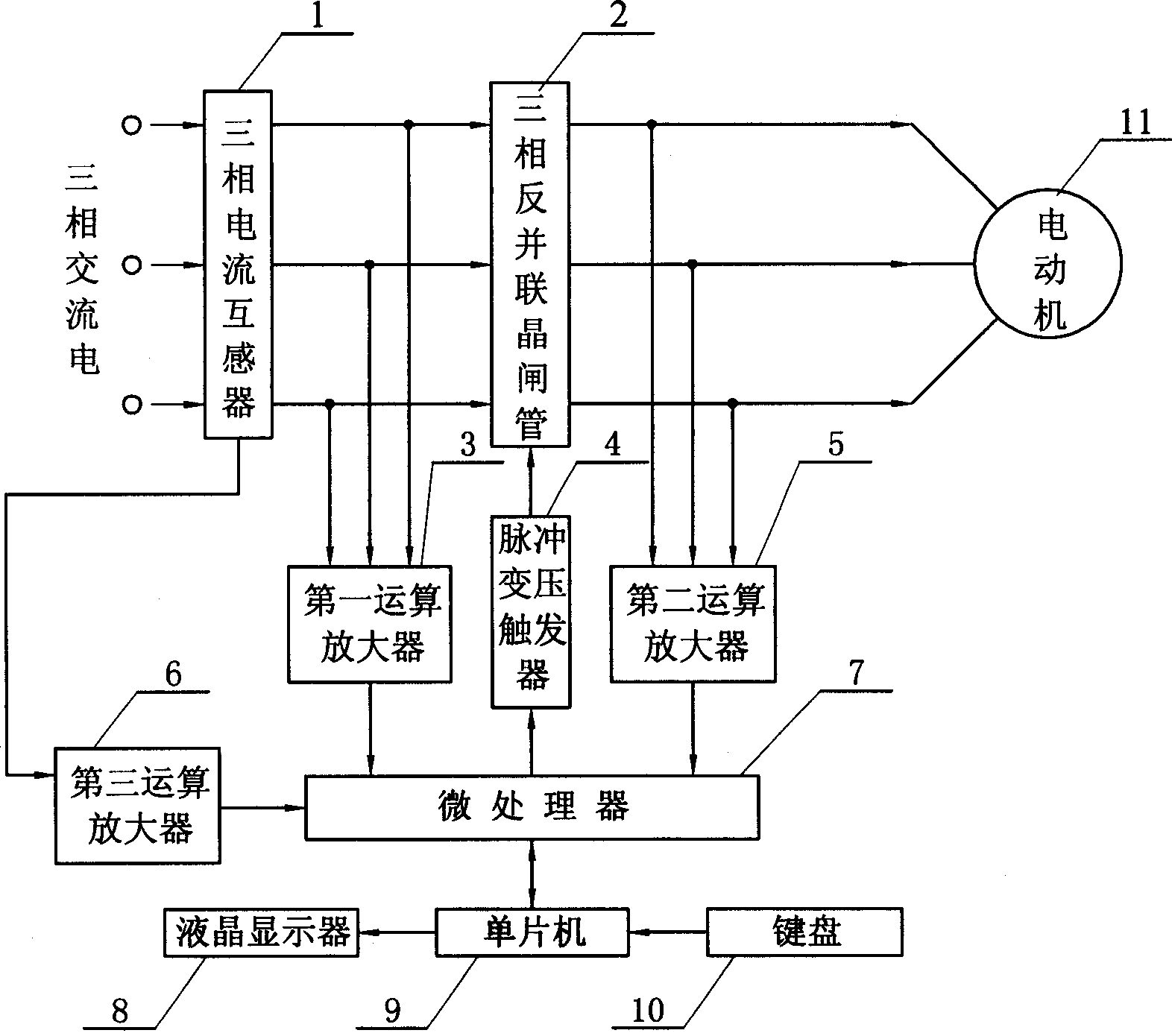

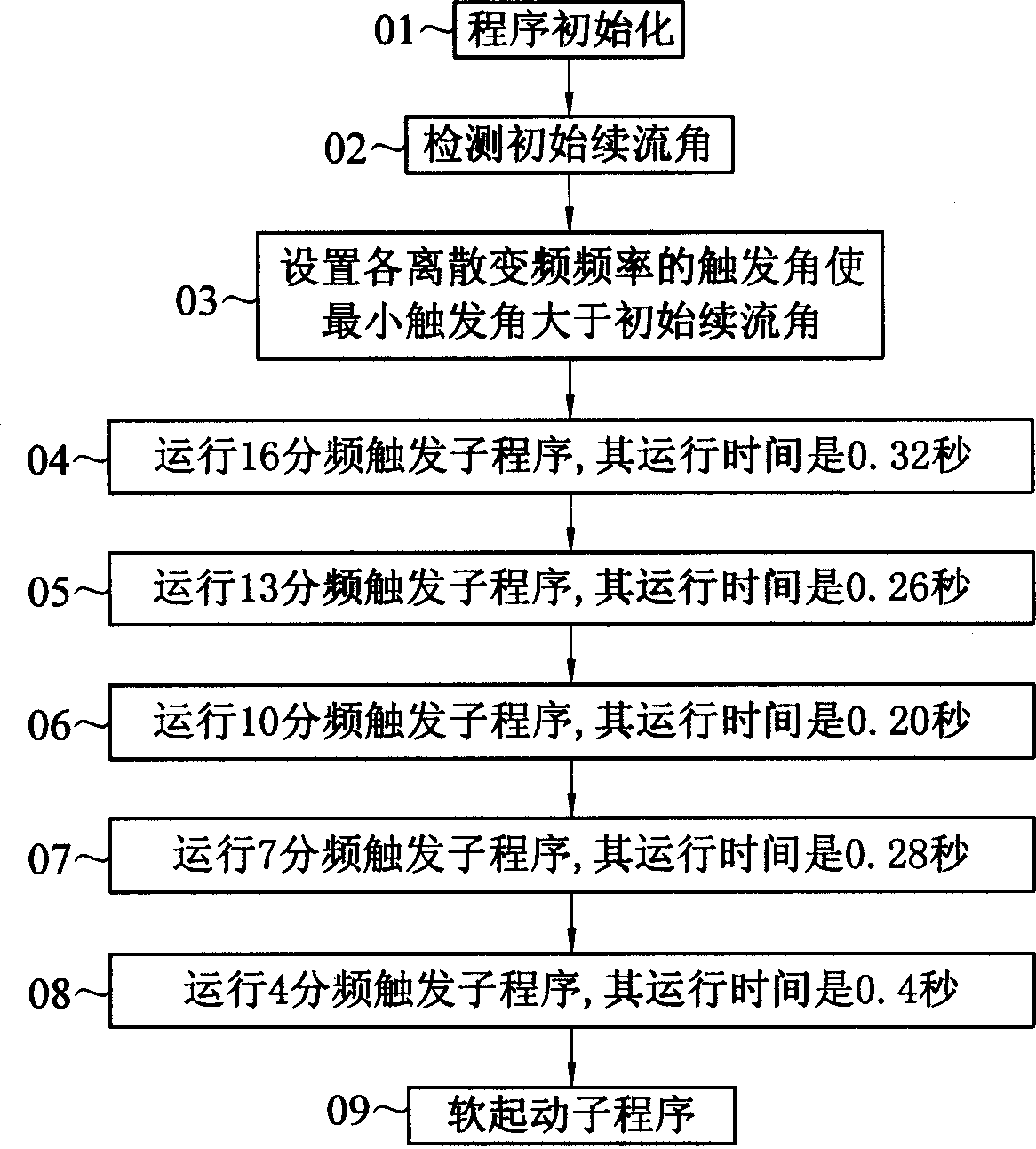

[0005] combine figure 1 , figure 2Describe this embodiment, this embodiment consists of a motor 11, a three-phase current transformer 1, a three-phase parallel thyristor 2, a first operational amplifier 3, a pulse transformer trigger 4, a second operational amplifier 5, a third operational amplifier 6, The microprocessor 7, the liquid crystal display 8, the single-chip computer 9, the keyboard 10 are composed; the three-phase alternating current is respectively connected with the three input terminals of the three-phase parallel thyristor 2 through the three-phase current transformer 1 and respectively connected with the three voltages of the first operational amplifier 3 The detection input terminals are connected, the three output terminals of the three-phase-inverse parallel thyristor 2 are respectively connected to the three input terminals of the motor 11 and are respectively connected to the three voltage detection input terminals of the second operational amplifier 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com