Semiconductor device and production method therefor

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as affecting electron transport, reducing device channel conduction, and suppressing interface energy level well density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

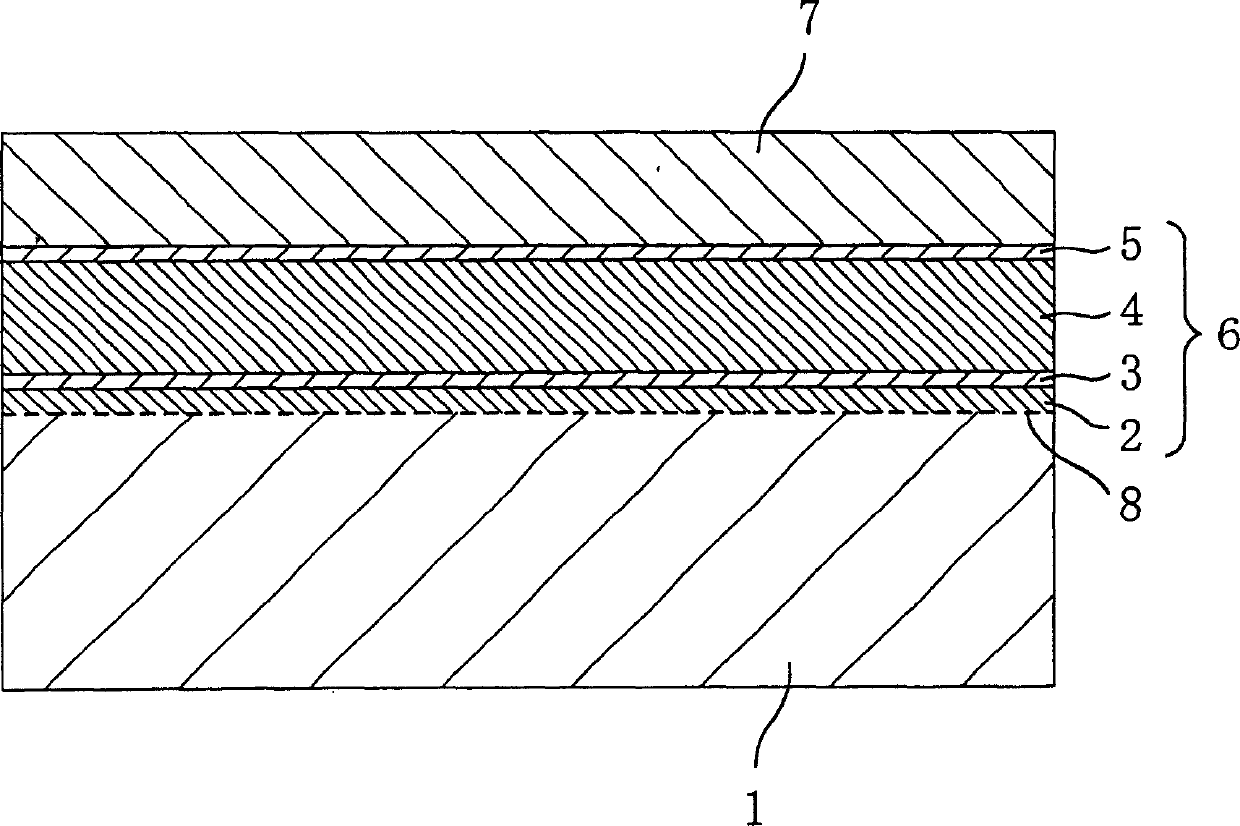

[0066] In this embodiment mode, a case where a first insulating film obtained by thermal oxidation of SiC and a second insulating film deposited by CVD or the like is formed as a gate insulating film of MISFET or the like will be described.

[0067] (Investigation by inventors etc.)

[0068] It is generally considered that when a silicon carbide MISFET is used in a low-loss power semiconductor device, a gate insulating film having a thickness of approximately 150 nm or more should be formed on silicon carbide.

[0069] However, this causes carbon to remain in the oxide film formed by thermal oxidation treatment on silicon carbide, and particularly, a high concentration of carbon remains in the vicinity of the interface with silicon carbide in the oxide film. Since the existence of such carbon is a cause of defects, the composition ratio of the transition layer should be changed more drastically from the gate insulating film side to the silicon carbide side.

[0070] Here, in ...

no. 2 approach

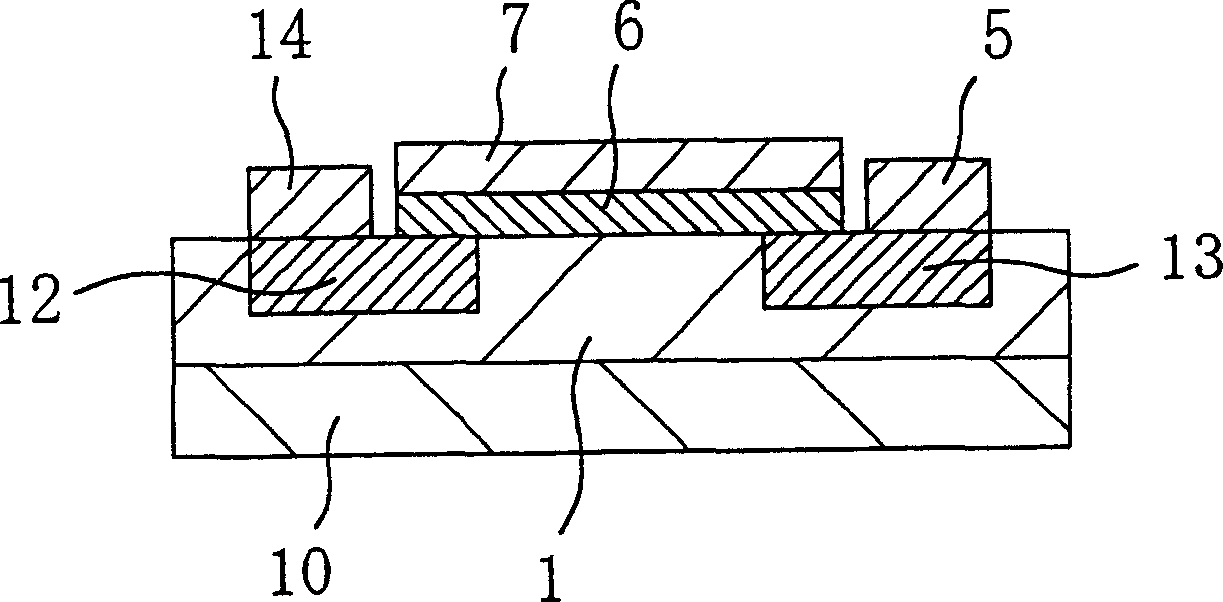

[0113] In this embodiment mode, an example in which the gate insulating film considered in the first embodiment mode is applied to a storage-enhanced insulated gate semiconductor device will be described.

[0114] Next, the structure near the gate insulating film in the semiconductor device according to the second embodiment of the present invention will be described with reference to FIG. 4 . 4 is a cross-sectional view showing a structure near a gate insulating film in a semiconductor device in a second embodiment.

[0115] As shown in FIG. 4, in the semiconductor device of the present invention, an n-type channel region 28 is formed on the top of the p-type SiC layer 21, and a gate insulating film 26 is formed thereon, which is a thermal oxide film with a thickness of about 5 nm. A first insulating film 22, an oxynitride film having a thickness of about 5 nm, that is, the first cover layer 23, a deposited oxide film having a thickness of about 130 nm, that is, the second in...

no. 3 approach

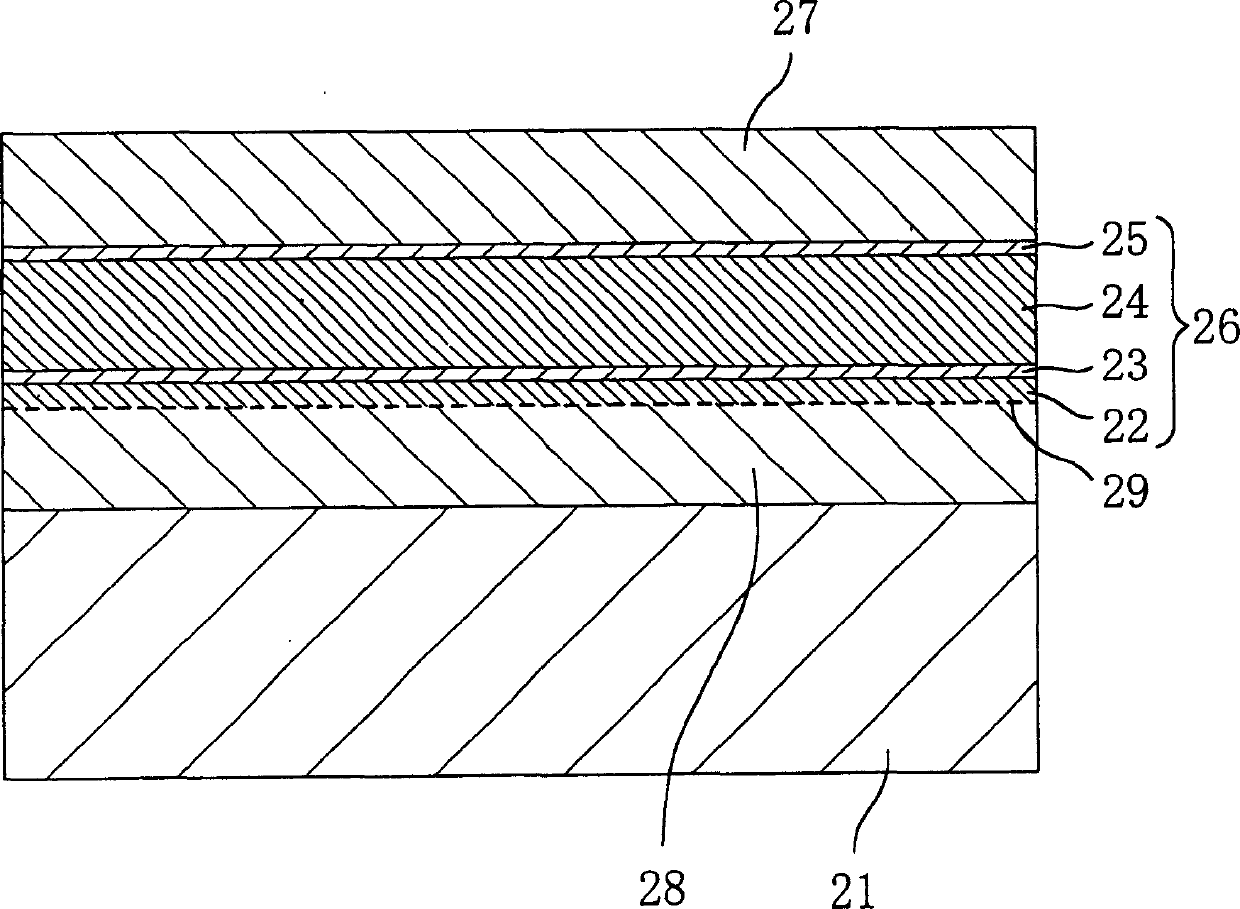

[0120] In this embodiment mode, an example in which the gate insulating film in the first embodiment mode is applied to an insulated gate type semiconductor device having a δ-doped layer will be described.

[0121] This embodiment mode is characterized in that the gate insulating film described in the first embodiment mode is formed on the δ-doped layer. Since the structure of this gate insulating film is the same as that of the first embodiment, description thereof will be omitted.

[0122] FIG. 8 is a cross-sectional view showing the structure of the semiconductor device in the third embodiment.

[0123] As shown in FIG. 8 , the semiconductor device of this embodiment includes an n-type SiC substrate 40 , a p-type SiC layer 41 formed on the SiC substrate 40 , and a channel region having a δ-doped layer formed on the top of the p-type SiC layer 41 . 46. The gate insulating film 47 formed on the channel region 46, the gate electrode 48 formed on the gate insulating film 47,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com