Grinding system intelligent optimization initialization method based on case ratiocination

A technology of intelligent optimization and setting method, applied in general control systems, control/regulation systems, electrical and digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

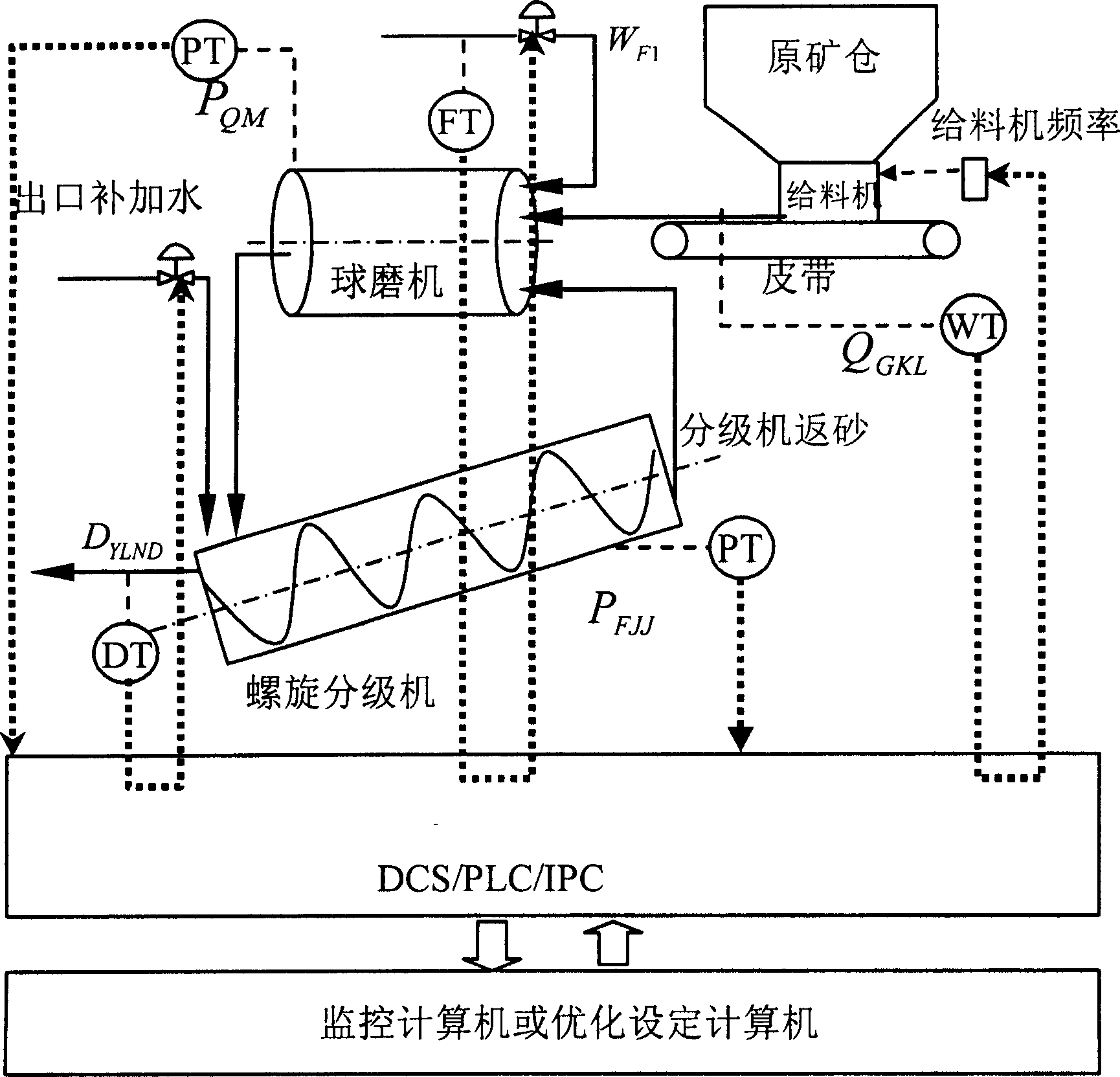

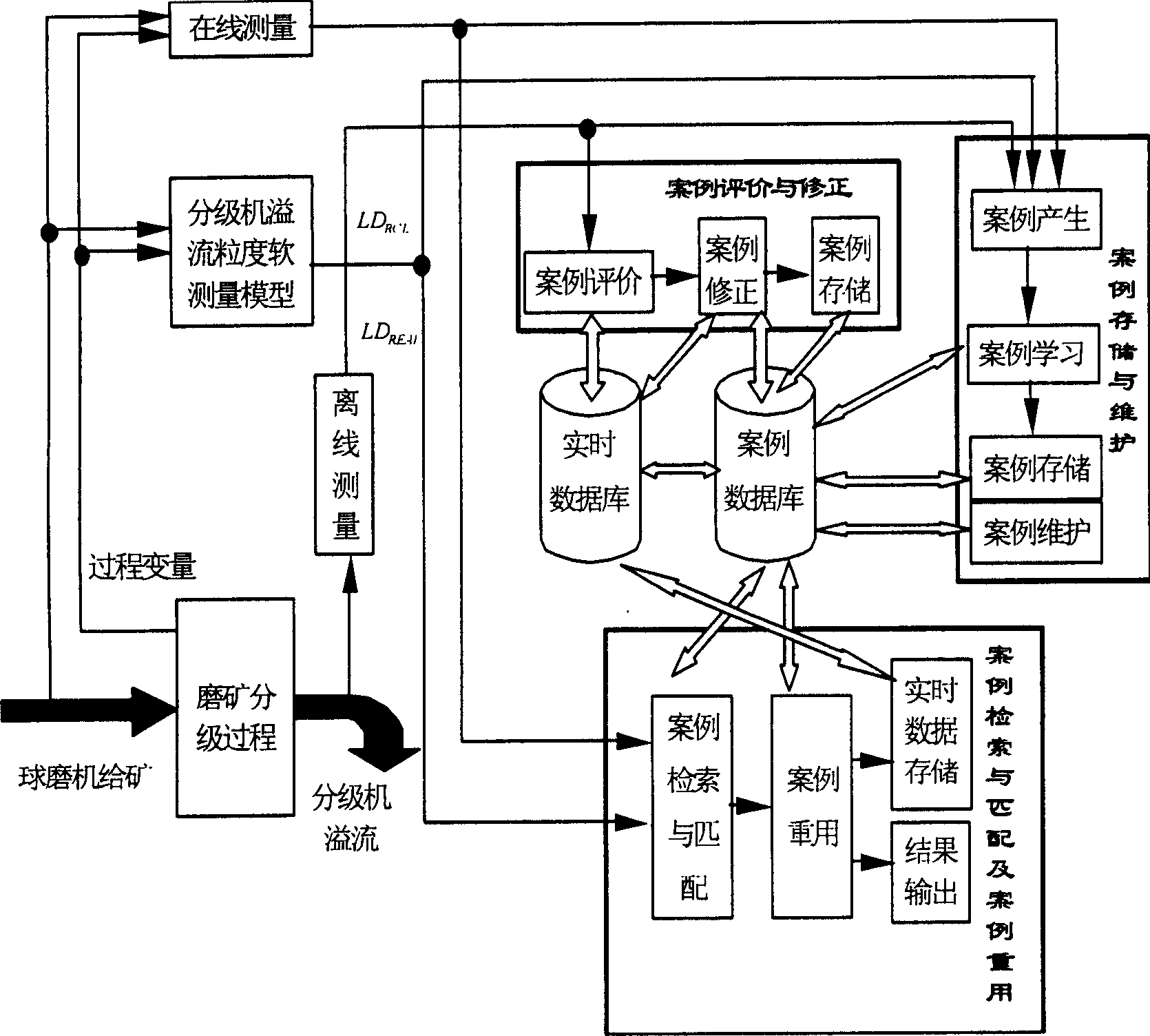

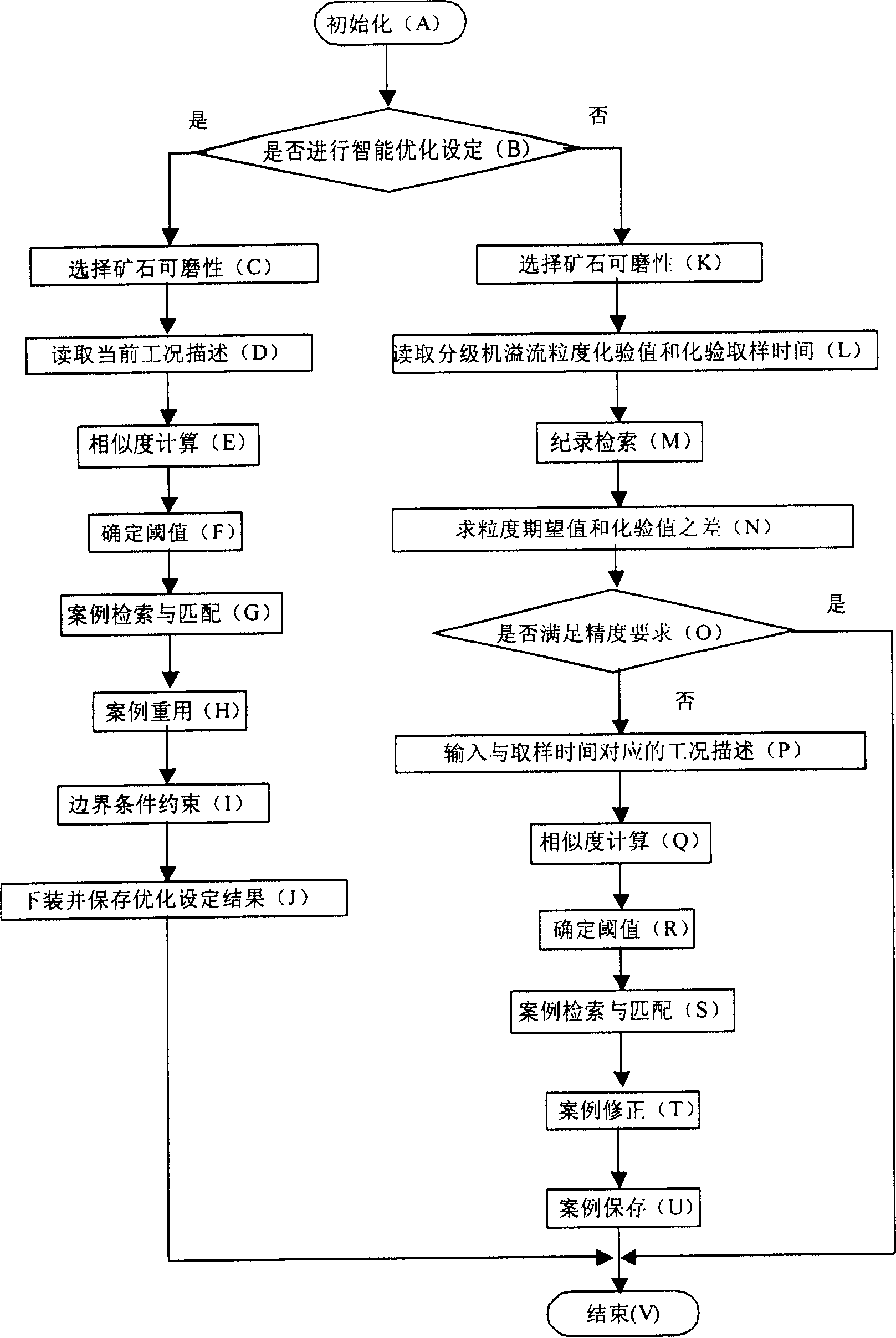

[0135] The embodiment of the present invention is a grinding series of the weak magnetic roasted ore of a large-scale iron ore concentrator. The main iron ores of this concentrator are pyrite and limonite, and the gangues are mainly barite, quartz, jasper and iron dolomite. The actual iron content of the ore is 33%. After sorting, the weak magnetic ore After the roasting process, it is transported to the weak magnetic separation cylinder bin. The schematic diagram of the grinding system is as follows figure 1 As shown, the roasted ore in the weak magnetic separation cylinder is discharged by the electric vibration feeder, and then sent into the ball mill by the ore belt conveyor, mixed with the additional water at the entrance of the ball mill, and ground into a pulp in the ball mill. The ore grinding adopts a grid type ball mill. The ore discharge of the ball mill and the supplementary water at the outlet of the ball mill enter the spiral classifier. The spiral classifier ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com