Sensing unit for magnetic resistance spinning valves temperature control switch

A temperature-controlled switch, spin valve technology, applied in temperature control, non-electric variable control, instruments, etc., can solve problems such as inability to CMOS circuits, unchangeable, and inability to freely set temperature thresholds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

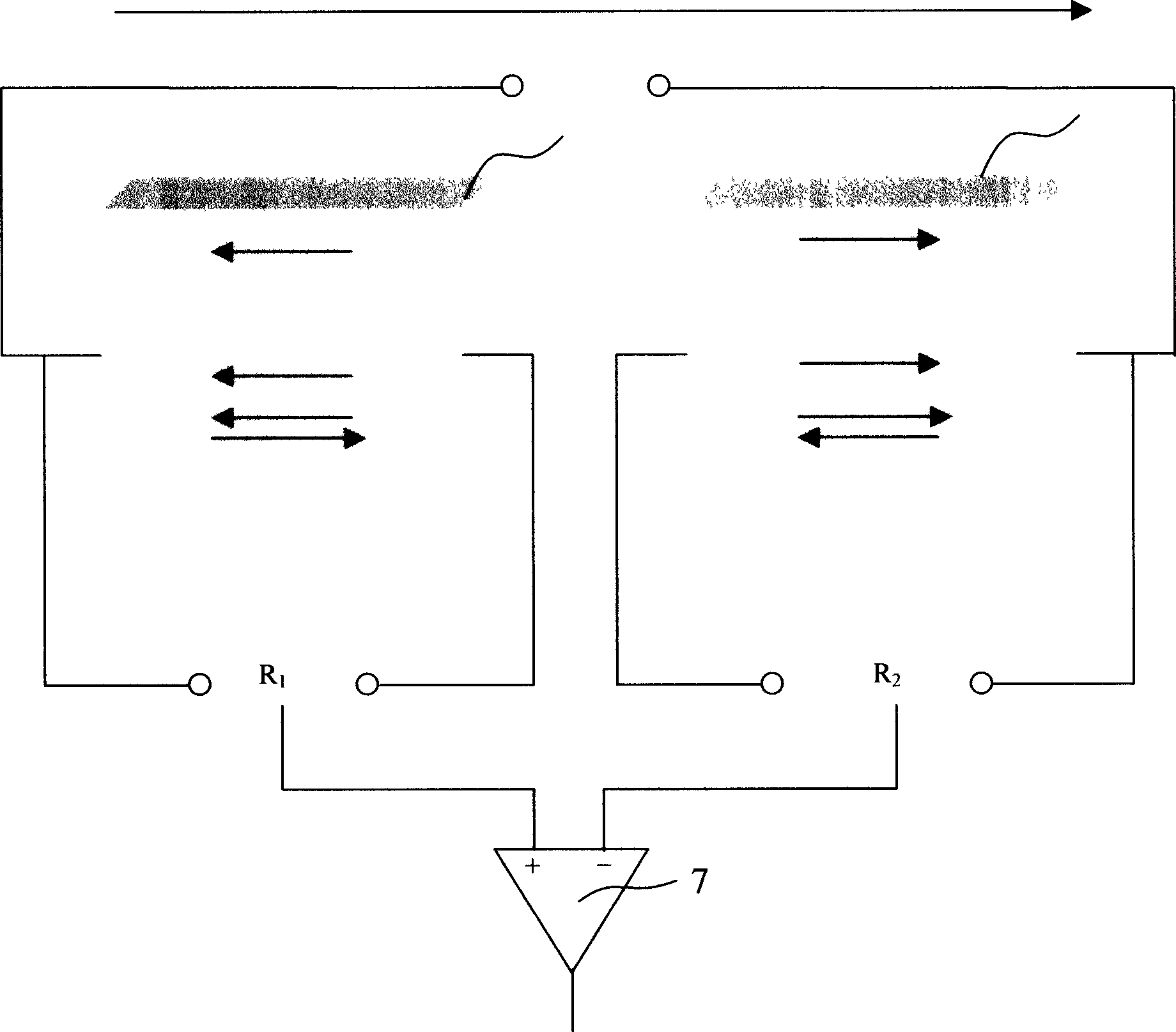

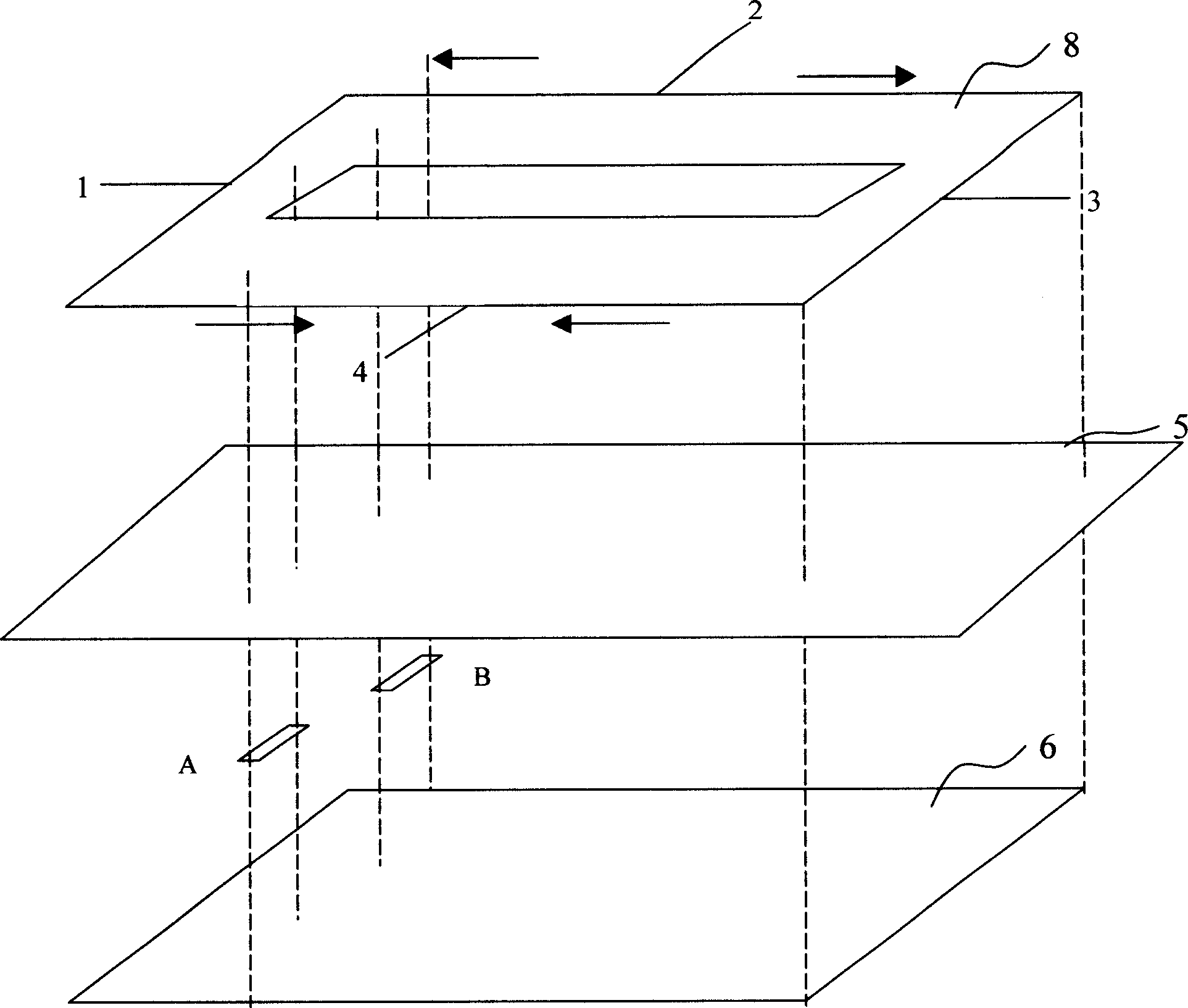

[0008] Such as figure 1 , 2 As shown, the present invention includes a chip base 6, a comparator 7, an insulating layer 3 and a fixed conductive layer 8, and the fixed electrical conductor includes and two power terminal pins 1, 3 and 2, 4; Formed with two spin valve elements A, B, such as figure 2 As shown by the dotted line in the middle, the fixed electric conductor layer 8 must cover the long sides of the two spin valve elements A and B, and an insulating layer 3 is arranged between the two spin valve elements and the fixed electric conductor, applied on the spin valve The magnetic field on the elements A and B is controlled by the current passing through the fixed electric conductor layer 8; the resistances of the spin valve elements A and B are compared by the comparator 7, and when the resistances of the spin valve elements A and B are not equal output signal. The spin valve elements A and B are formed on the substrate by photolithography or mask method, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com