Rotary powder compression molding machine

A compression molding and rotary technology, applied in the direction of presses, material forming presses, electrostatic spraying devices, etc., can solve problems such as contamination, uneven adhesion of powder lubricants, and half the manufacturing speed of tablets, so as to prevent scattering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Next, an embodiment of the present invention will be described with reference to the drawings.

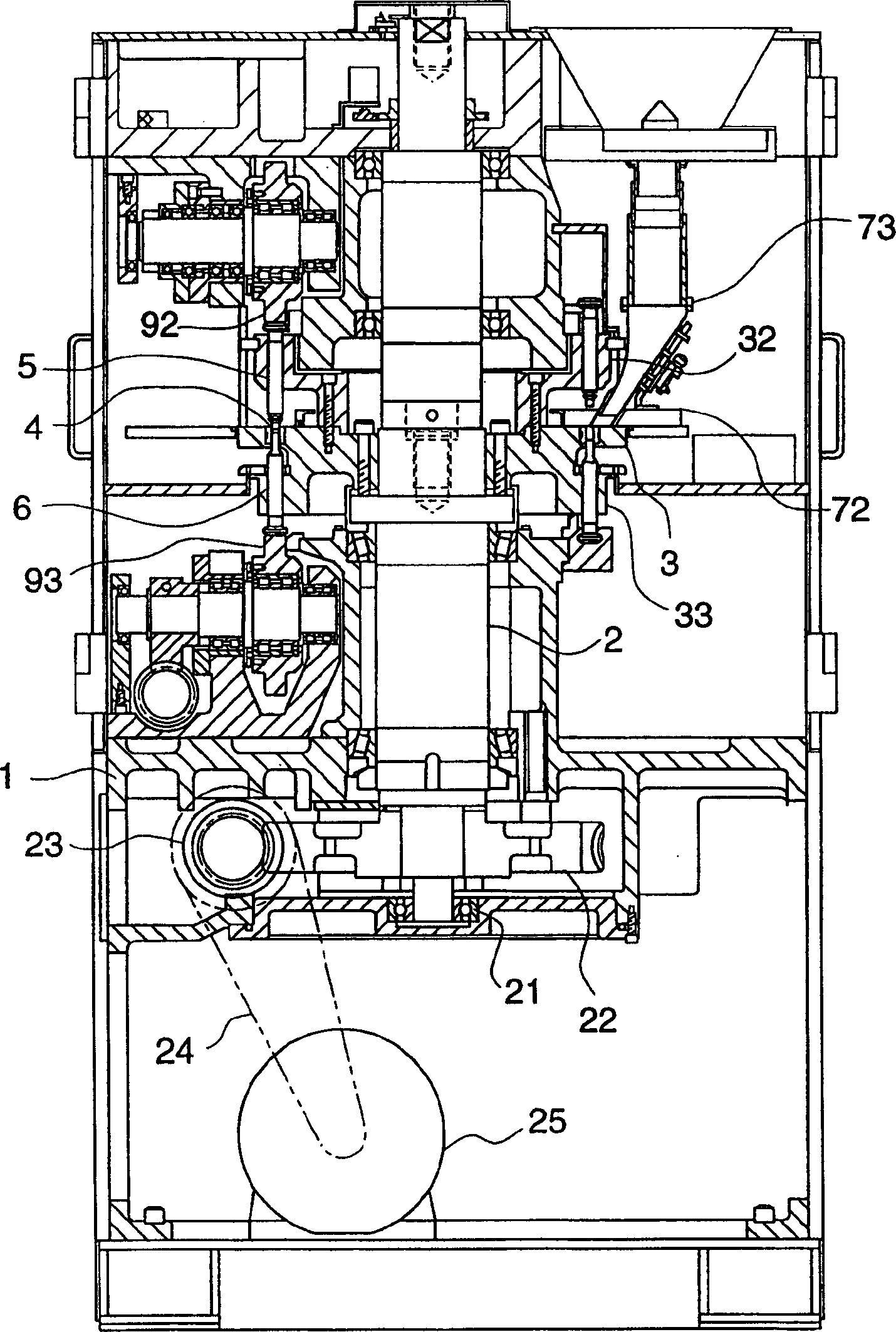

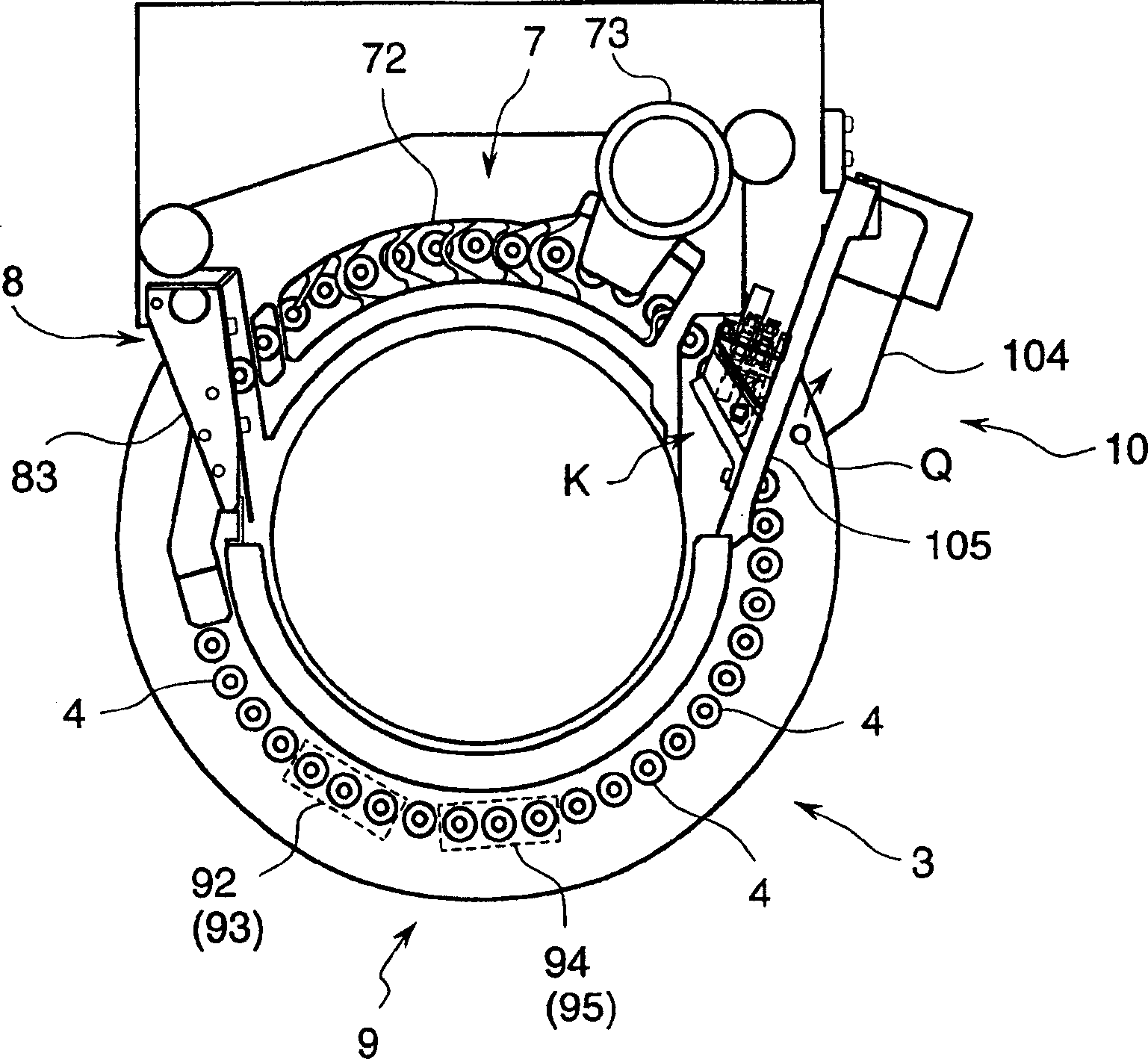

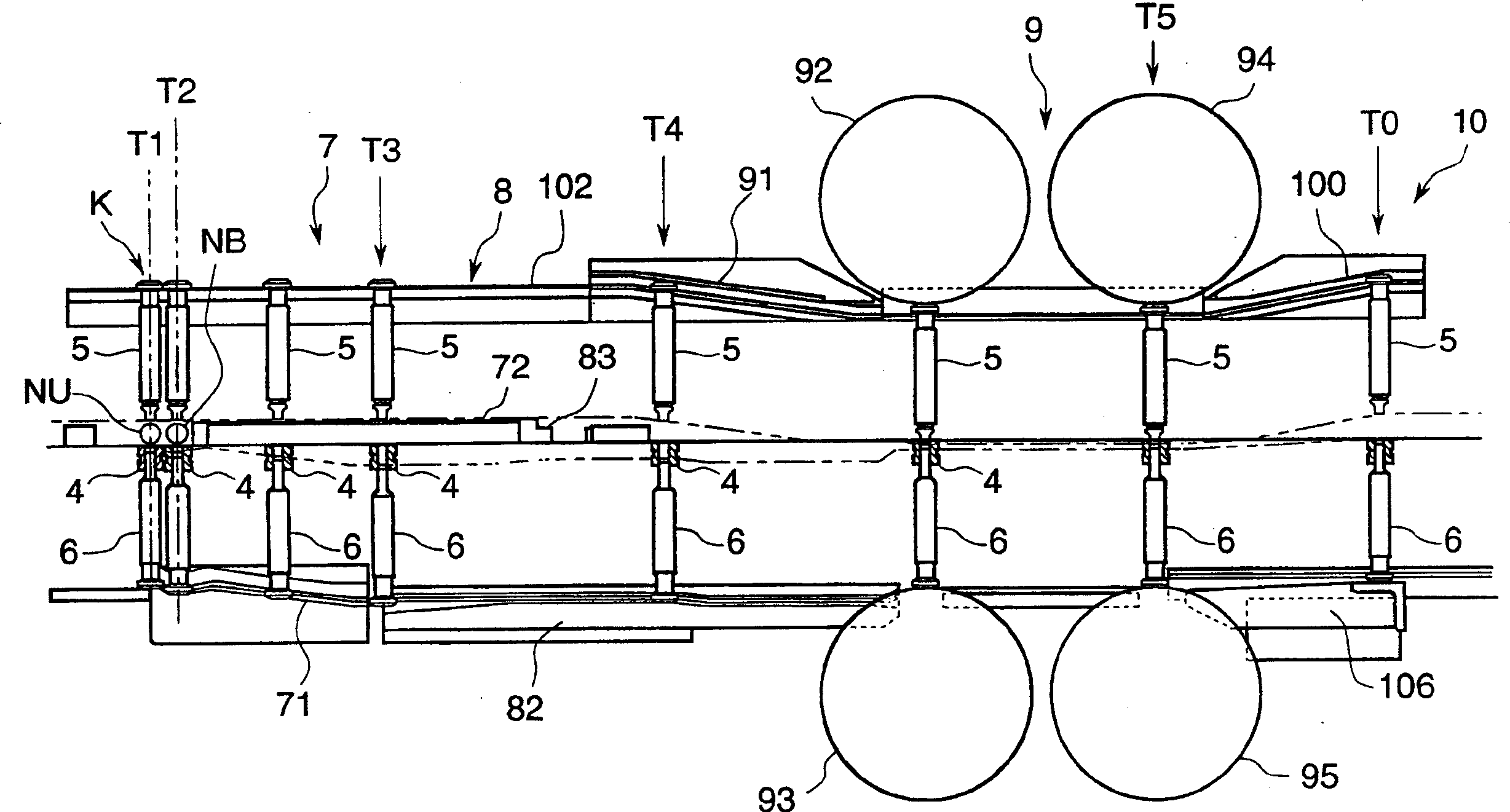

[0038] figure 1 In , the overall structure of the rotary powder compression molding machine of the present invention is shown. This rotary powder compression molding machine is equipped with a powder lubricant injection device LS ( Figure 9 ). In the frame 1, a rotating disk 3 that can rotate horizontally is arranged through a vertical shaft 2. On the rotating disk 3, several mortars 4 are arranged at predetermined intervals. The last pestle rod 5 and the following pestle rod 6.

[0039]Specifically, a vertical shaft 2 supported by a bearing 21 is disposed at approximately the center of the frame 1, and a worm wheel 22 is fixed near the lower end of the vertical shaft 2. As shown in FIG. The rotational driving force of the motor 25 is transmitted to the worm wheel 22 through the worm 23 and the belt 24 . Near the head of the vertical shaft 2, a rotating disk 3 divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com