Energy conservation electric arc sparking plug

A spark plug and electric arc technology, applied in the field of spark plugs, can solve the problems of reduced engine output, oil accumulation, insufficient fuel combustion, etc., to achieve the effects of ensuring output power, reducing oil accumulation, and sufficient fuel combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

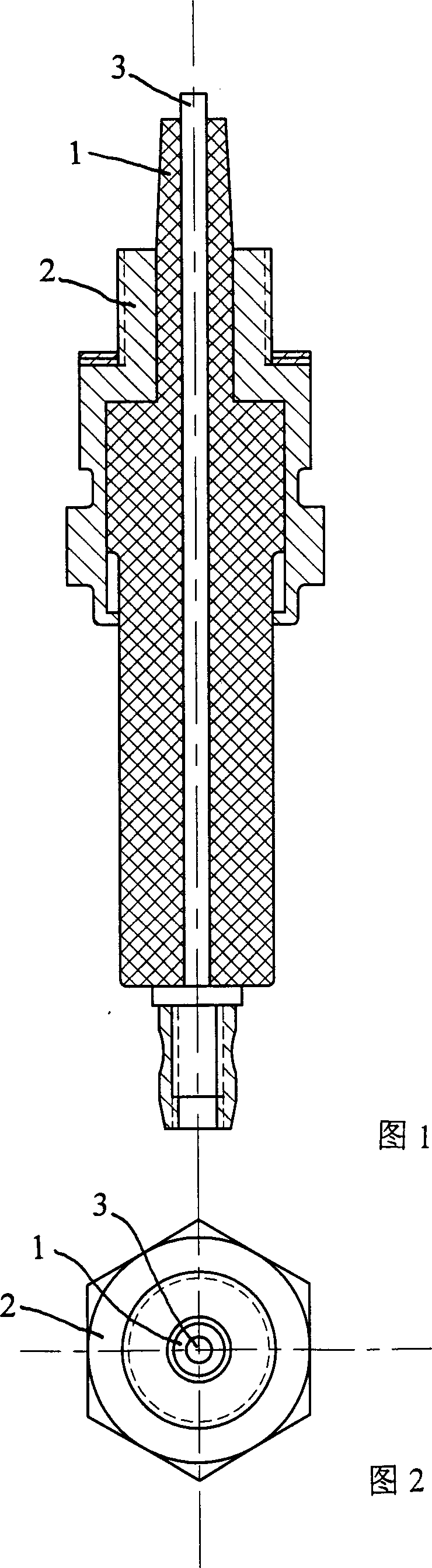

[0012] As can be seen from Fig. 1 and Fig. 2, the energy-saving arc spark plug of the present invention includes a ceramic insulating sleeve 1, a metal threaded sleeve 2 is placed on the outer cover of the ceramic insulating sleeve 1, and a high-voltage discharge rod 3 is arranged inside the ceramic insulating sleeve 1, and the high-voltage discharge rod The discharge end of 3 protrudes from one end of insulating sleeve 1. The wall thickness of insulating sleeve 1 located at the discharge end of high-voltage discharge rod 3 is 1-3 mm. The length of the discharge end of high-voltage discharge rod 3 protruding from the end of insulating sleeve 1 is 2 mm, which can also be 1-3mm. The distance between the discharge end of the high-voltage discharge rod 3 and the metal threaded sleeve 2 is 12-15mm, or 10-25mm, or 8-30mm.

[0013] The energy-saving arc spark plug of the present invention overcomes the prejudice existing in the prior art, cancels another rod-shaped electrode and repl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com