Backlight module

A backlight module and fluorescent technology, applied in optics, optical elements, diffraction gratings, etc., can solve the problems of poor light uniformity and low light source utilization of backlight modules, and achieve consistent brightness, high light uniformity, and brightness high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

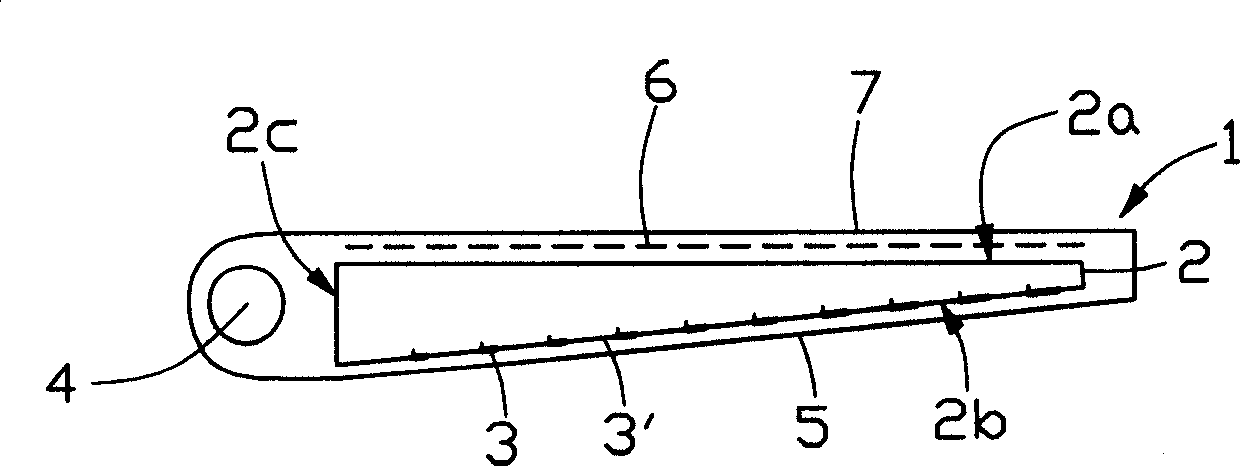

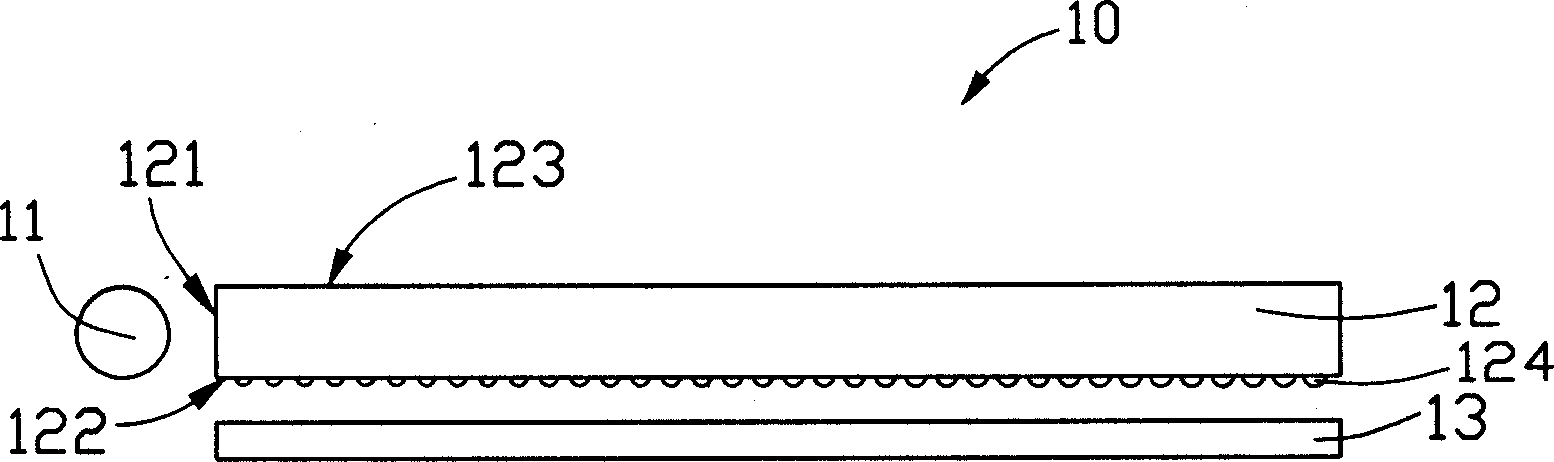

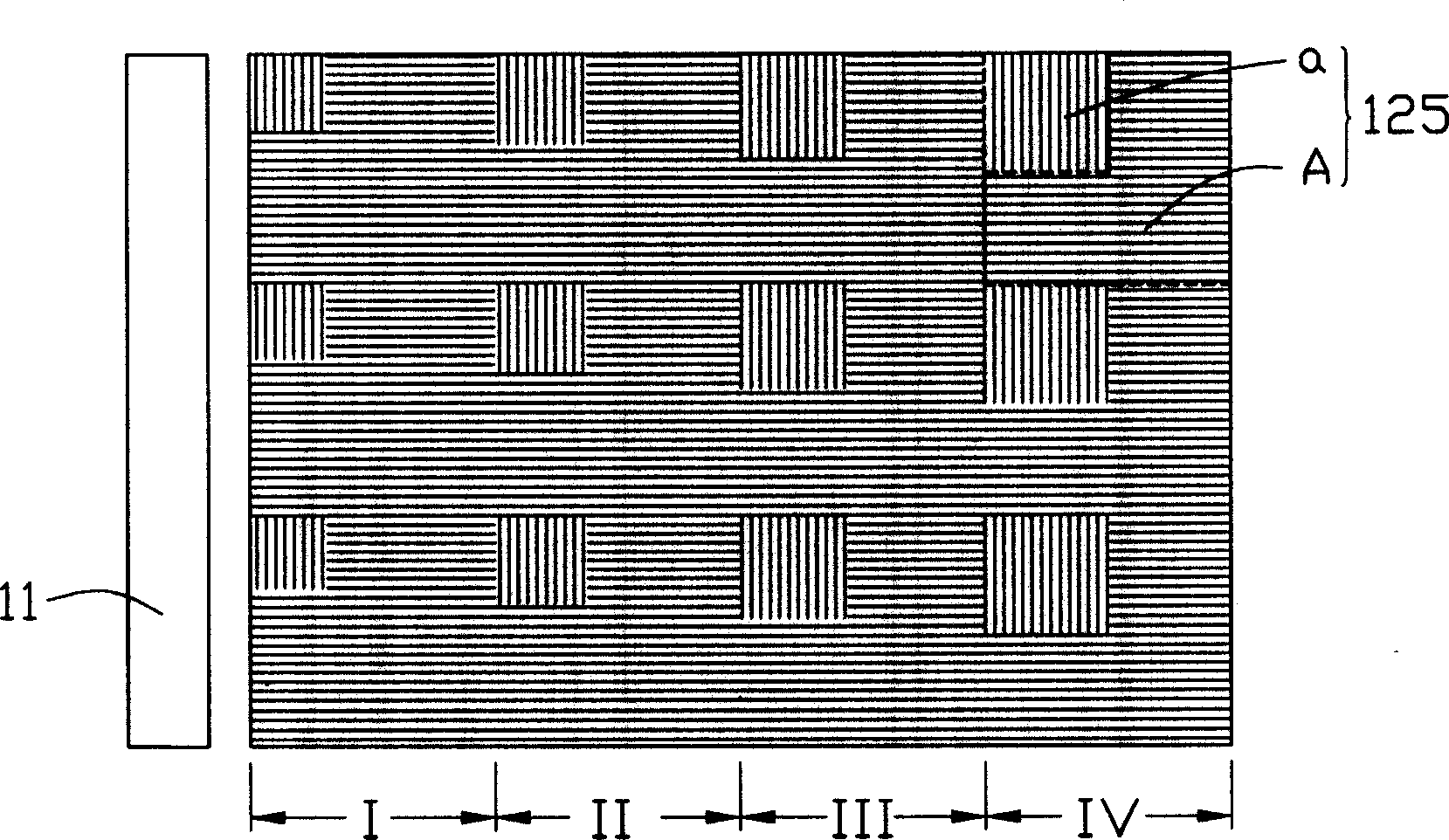

[0015] see figure 2 and image 3 According to the first embodiment of the present invention, the backlight module 10 includes a line light source 11 , a light guide plate 12 and a reflective sheet 13 . Wherein, the line light source 11 is a cold cathode fluorescent lamp (Cold Cathode Fluorescent Lamp, CCFL), the light guide plate 12 includes a light-emitting surface 123 provided with a plurality of transmissive grating units 125, and a set opposite to the light-emitting surface 123, Furthermore, it has a bottom surface 122 with a plurality of dots 124 and a fluorescent coating (not shown in the figure), and a light incident surface 121 connected with the light exit surface 123 and the bottom surface 122 . The line light source 11 is disposed adjacent to the light incident surface 121 of the light guide plate 12 , and the reflection sheet 13 is disposed opposite to the bottom surface 122 of the light guide plate 12 .

[0016] The light guide plate 12 is flat and made of tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com