Method of recovering waste sulfuric acid and waste gas produced in tatanium dioxide production

A technology of production process and recovery method, applied in the direction of separation method, chemical instrument and method, sulfur compound, etc., can solve problems such as furnace exhaust gas and waste acid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] ① Send the kiln waste gas and waste sulfuric acid produced in the production process of titanium dioxide to the "titanium dioxide kiln tail gas enrichment and sulfuric acid graphite tower" (using Chinese patent: ZL01217393.2 structure form) for mixing, gas-liquid contact, and concentration. And further into the gas-liquid separator, gas-liquid separation, so that the waste gas takes away part of the water in the acid, and concentrates the acid to a concentration of about 30%. At this time, the acid contains a small amount of titanium dioxide and raw A small amount of titanium dioxide contained in waste acid;

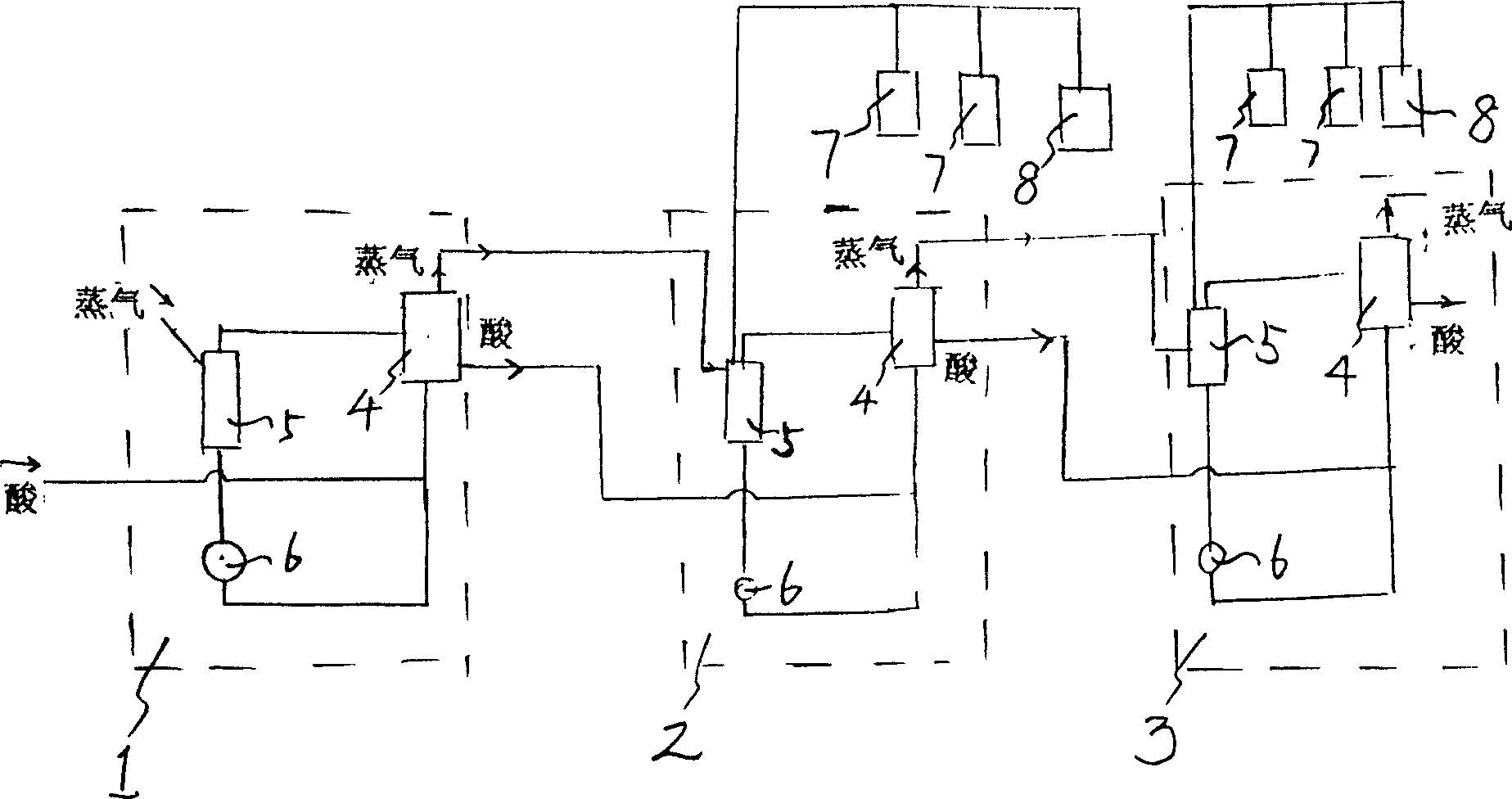

[0016] ②The separated waste acid liquid is sent to the solid-liquid separator to separate the acid from the titanium dioxide contained in it, and the acid liquid obtained after separation enters the steam concentration system for concentration treatment. The steam concentration system has a first-level one-effect steam concentration device 1, a first-level one-eff...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap