Rotary kiln riding wheel axle laser projection calibrating kiln method and riding wheel axle laser projector

A technology of laser projection and laser transmitter, applied in instruments, optical devices, measurement devices, etc., can solve the problems of difficulty in popularization and application, complicated measurement process, etc., and achieve the effect of easy popularization and application, simple measurement instrument, and improved measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

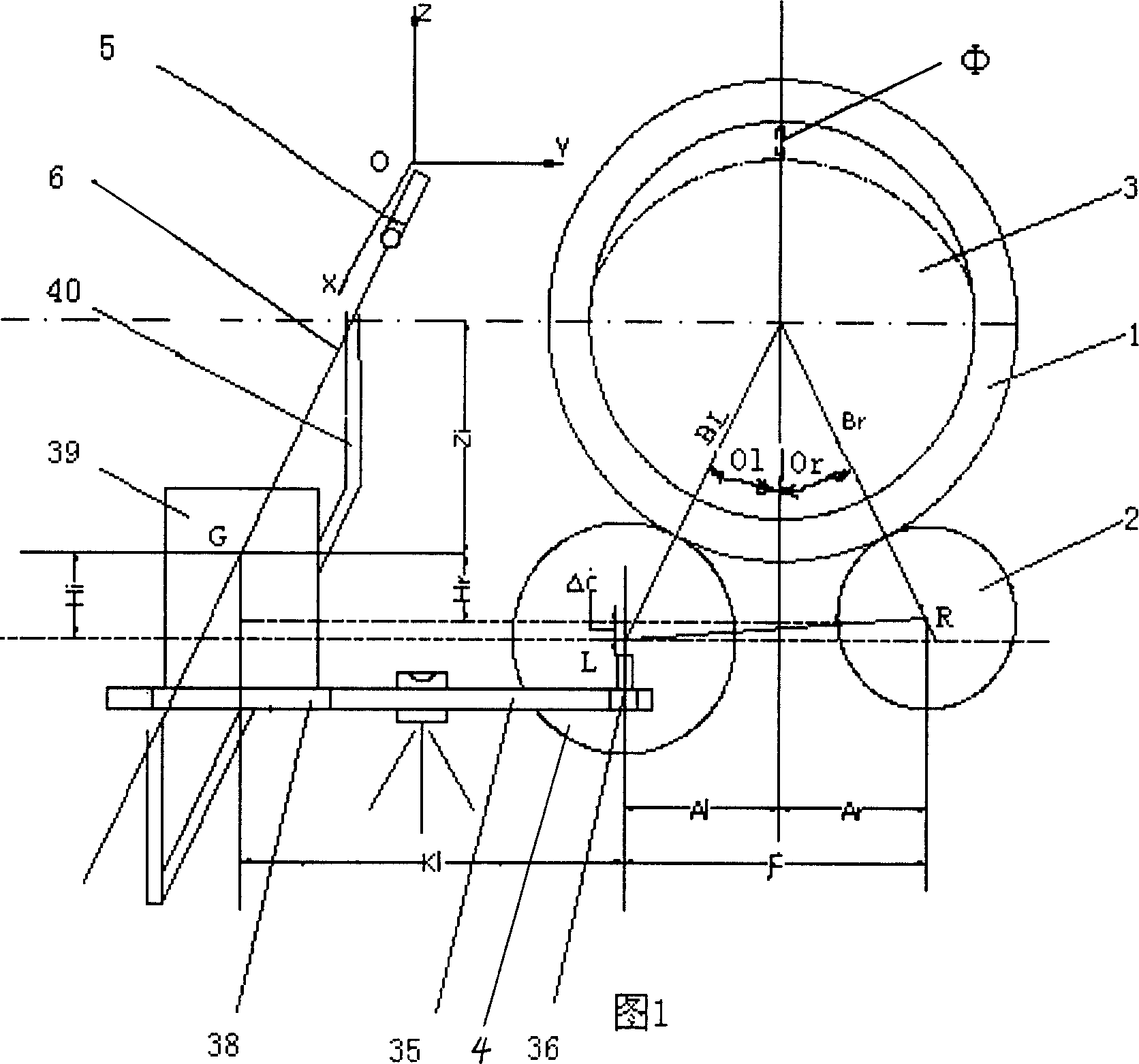

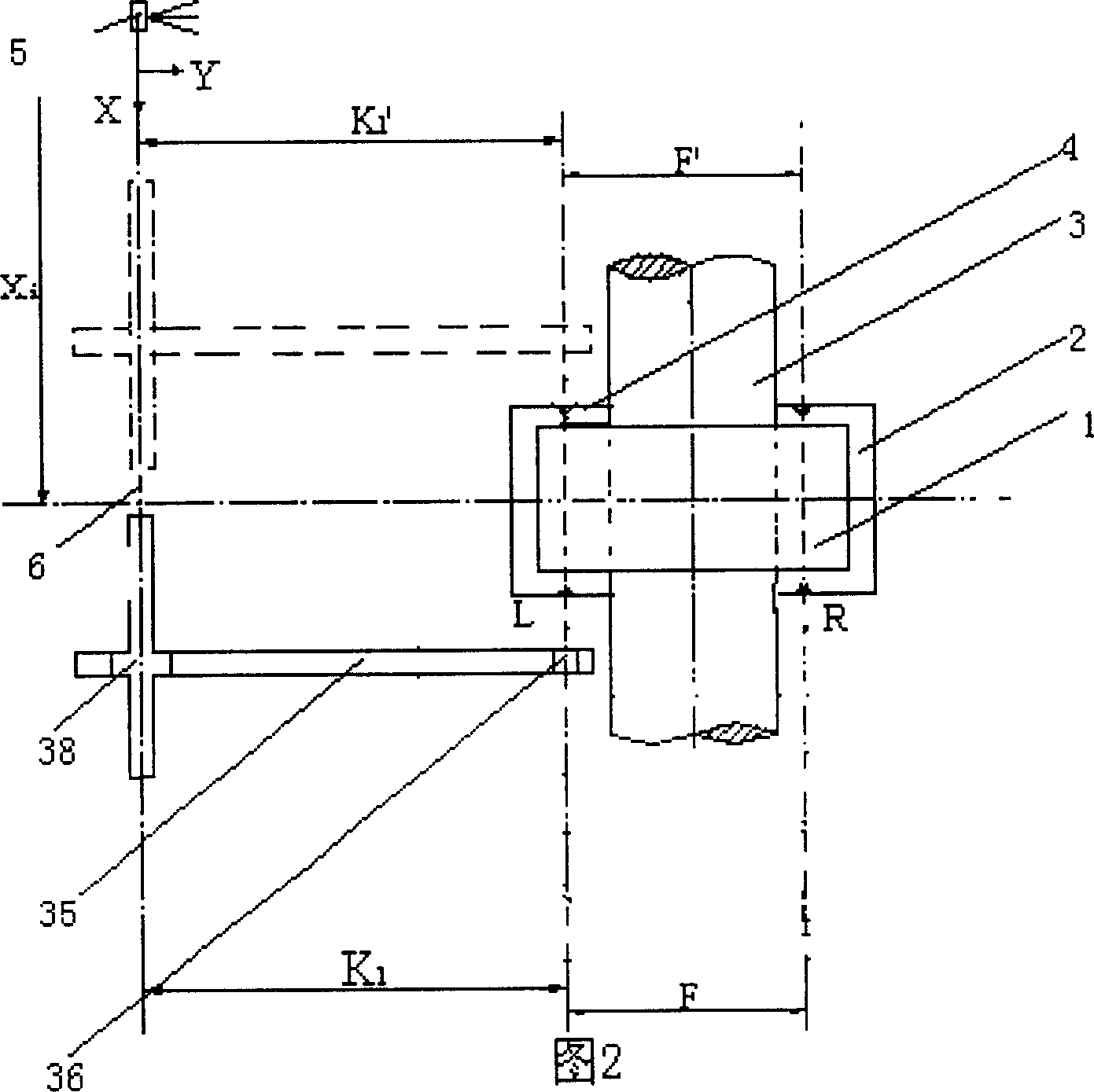

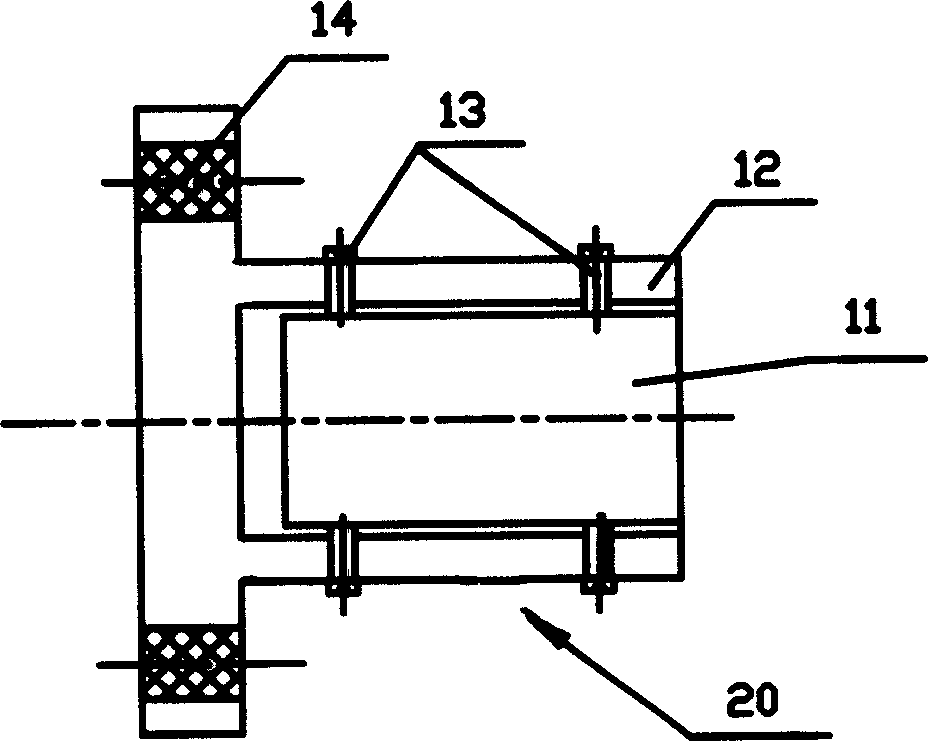

[0033] In the following, the method for laser projection and calibration of the rotary kiln supporting wheel shaft and the supporting wheel shaft laser projector of the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments:

[0034] With reference to the drawings, the measuring instruments used in the method of the present invention mainly include: laser collimator 5, two specially designed roller shaft laser projectors 20, sliding ruler 35, steel tape measure, dynamic diameter measuring instrument, and the gap between the tires 1 ΦDynamic tyre gap meter and microcomputer with program for measuring. Among them: the laser collimator 5, the steel tape measure are the existing general instruments and tools; the sliding scale 35, the dynamic diameter measuring instrument, and the dynamic tyre gap gauge are the existing special instruments; the program in the microcomputer, the person skilled in the art according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com