High voltage pulse electric field processing device

A technology of high-voltage pulsed electric field and high-voltage pulsed power supply, which is applied in the field of high-voltage pulsed electric field processing devices to achieve the effects of fast aging and convenient processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

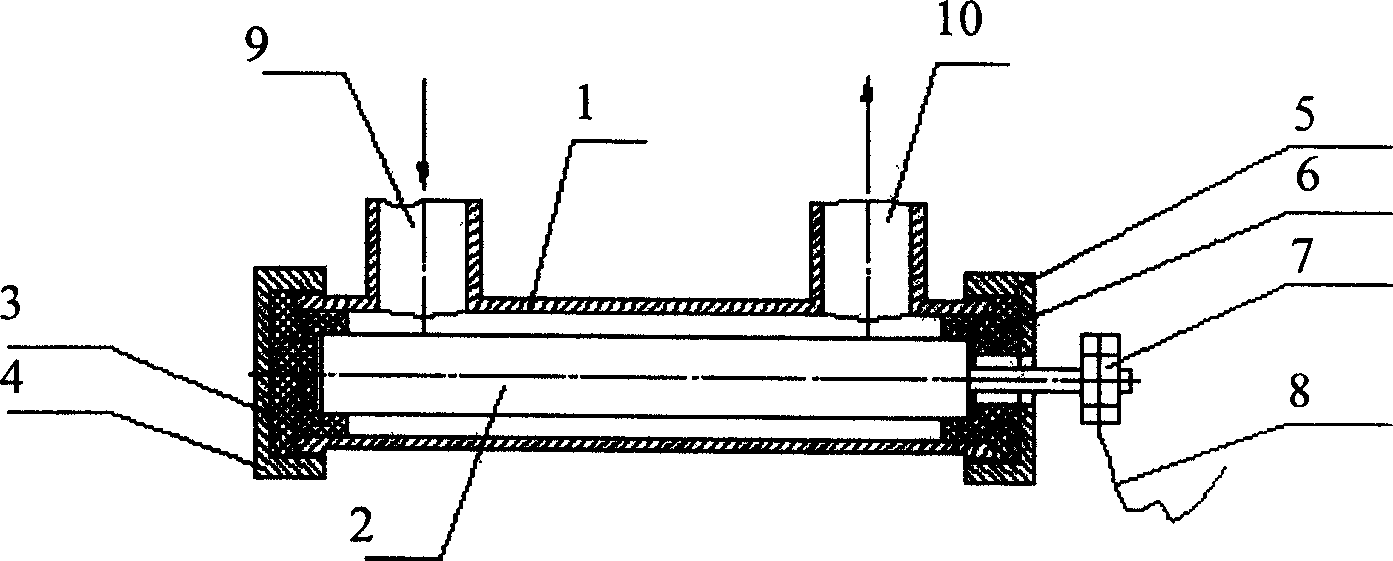

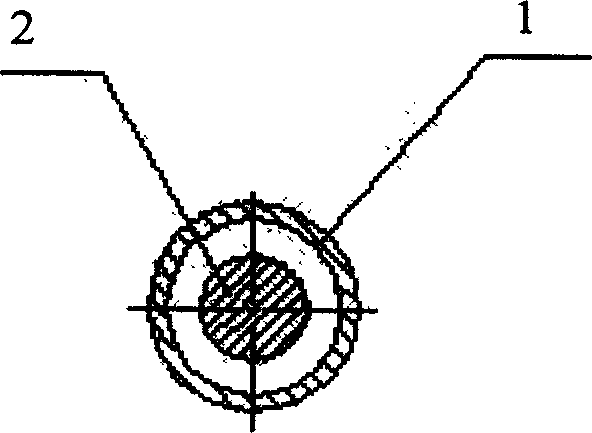

[0014] refer to figure 1 , figure 2 , a high-voltage pulse electric field processing device, which is composed of two electrode plates respectively connected to two electrodes of a controllable high-voltage pulse power supply. The same hollow tube, the two hollow tube plates 1, 2 are coaxially set together, the two ends of which are separated by the insulator spacer rings 3, 6, fixed and closed by the insulator spacer ring fixing discs 4, 5, in the The annular gap formed between the two hollow tube plates 1 and 2 is a cavity for carrying materials to be processed, and the outer plate 1 is provided with material inlets and outlets 9 and 10 communicating with the cavity.

[0015] The cross-sectional shape of the hollow tube electrode plates 1 and 2 may be circular or rectangular, rhombus, or oval. Among the figure, 7 is an electrode lead terminal, and 8 is a pulse power lead.

Embodiment 2

[0017] Another structural form of the high-voltage pulsed electric field processing device of the present invention:

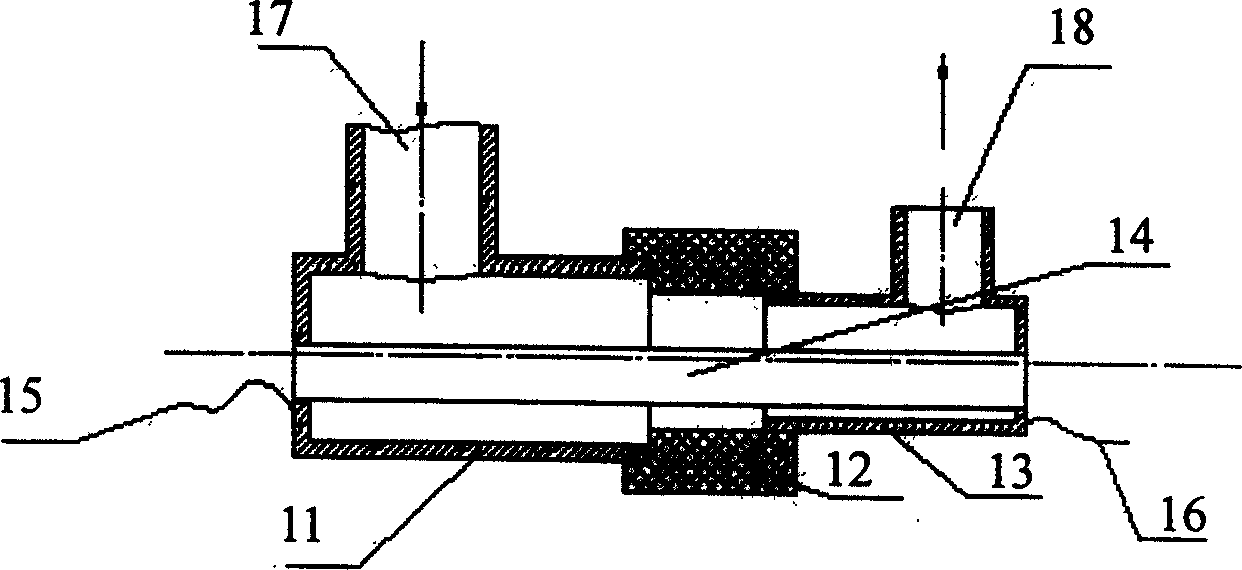

[0018] refer to image 3 , Figure 4 , the high-voltage pulse electric field processing device is composed of two electrode plates respectively connected to the two poles of the controllable high-voltage pulse power supply, the two electrode plates 11, 13 are two hollow tubes, and the two hollow tube electrode plates 11, One end of 13 is sealed and butted together by insulator isolation ring 12, and the cavities formed in the two hollow tube plates 11, 13 are the cavities for carrying materials to be processed, corresponding to the cavities of the two-point plates 11, 13. An insulator mandrel 14 whose radial dimension is smaller than that of the insulator isolation ring 12 is also erected at the insulator isolation ring 12 . The two hollow tube electrode plates 11, 13 are respectively provided with material inlets and outlets 17, 18 communicating with the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com