Electro-optic device, substrate for electro-optic device and method for manufacturing the same, photomask, and electronic device

An electro-optical device and mask technology, which can be used in microlithography exposure equipment, optomechanical equipment, photolithographic process exposure devices, etc., can solve the problems of insufficient light scattering and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Embodiments of the present invention will be described below with reference to the drawings. The following exemplifies the application of the present invention to a liquid crystal display device using a liquid crystal as an electro-optical device, but it is not intended to limit the applicable range of the present invention. In addition, in each of the drawings shown below, the dimensions and ratios of the respective constituent elements are different from actual ones for convenience of description.

[0053]

[0054]

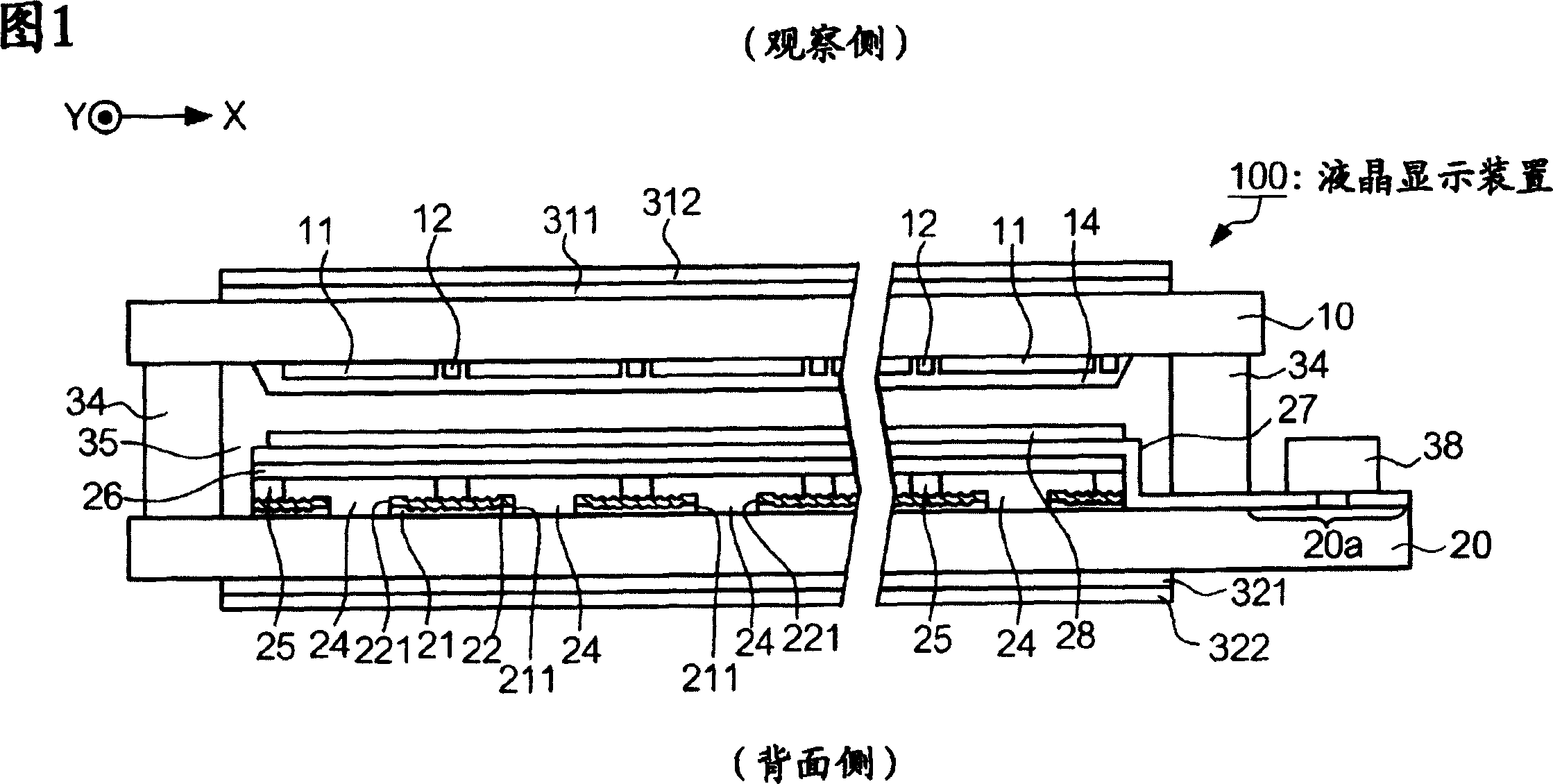

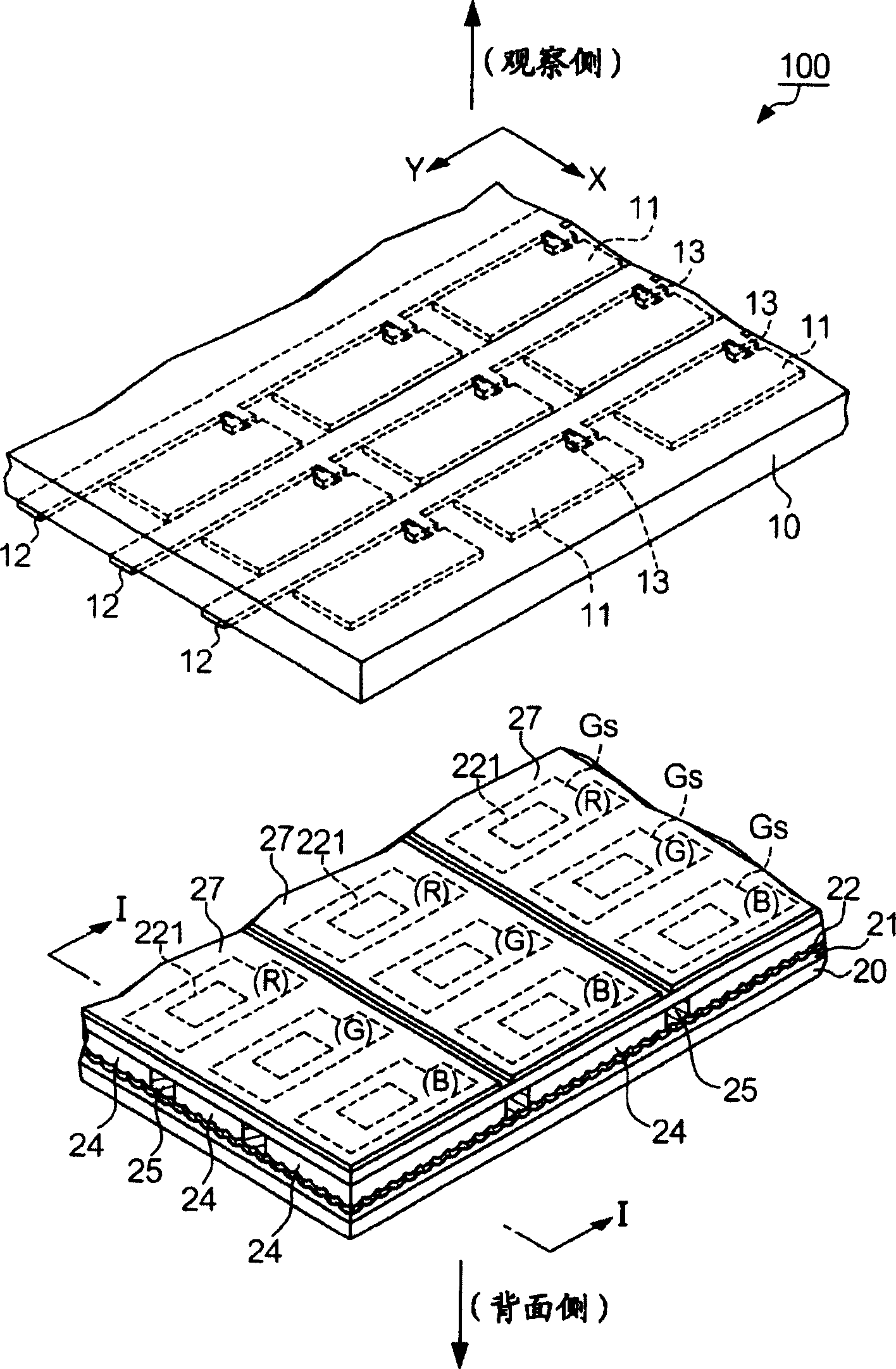

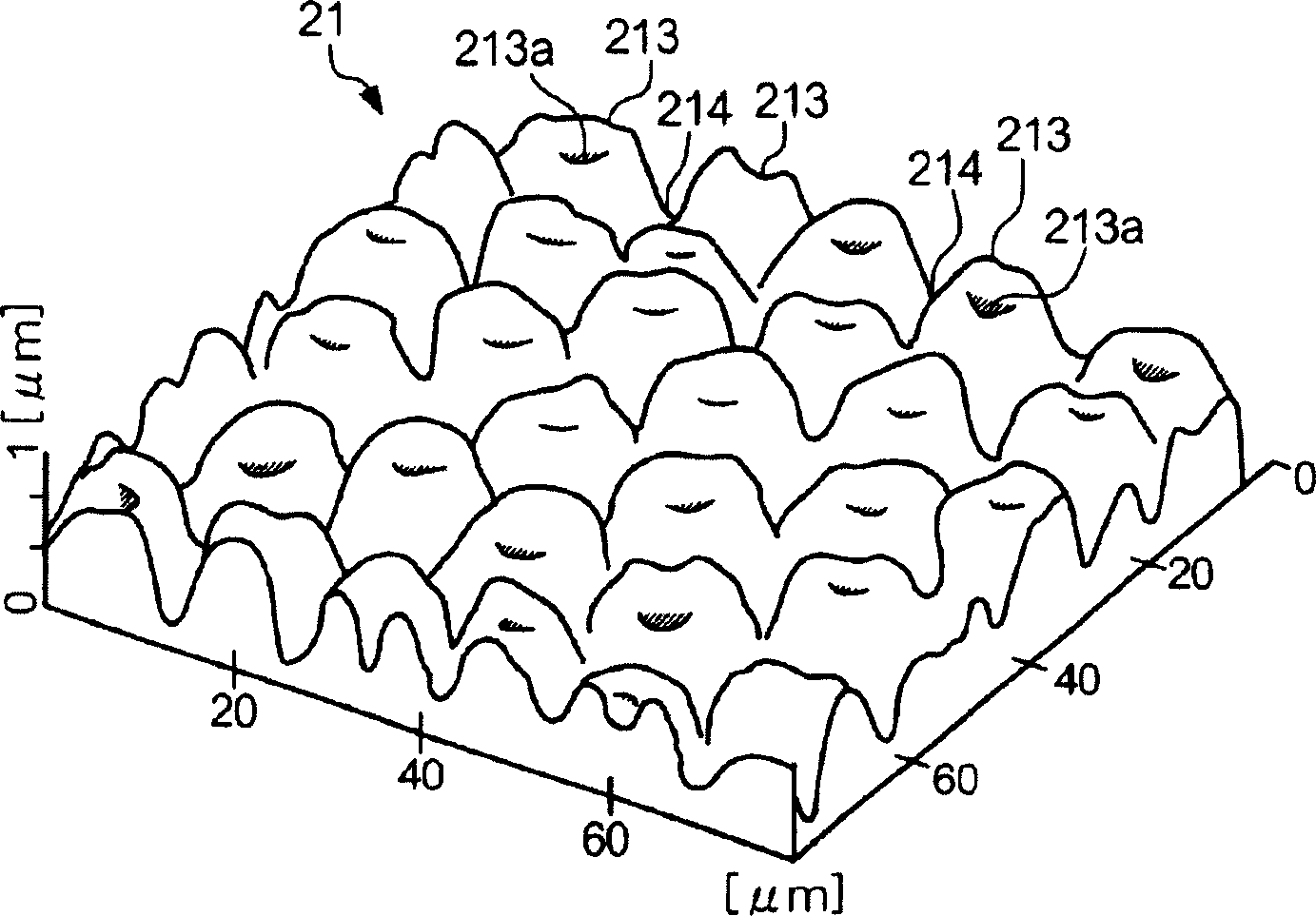

[0055] FIG. 1 is a cross-sectional view showing the configuration of a liquid crystal display device according to this embodiment, figure 2 It is an enlarged perspective view showing a part of this liquid crystal display device. From figure 2 The cross-sectional view of the I-I line observation is equivalent to that in Figure 1. As shown in these figures, the liquid crystal display device 100 has a first substrate 10 and a second substrate 20 tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com