Anti-glare Anti-reflection hard coating film, image display device, and method for producing Anti-glare Anti-reflection hard coating film

A manufacturing method and anti-reflection technology, applied in chemical instruments and methods, diffusion elements, nonlinear optics, etc., can solve the problem of high price, and achieve the effects of suppressing reflection, providing reflection, and suppressing glare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

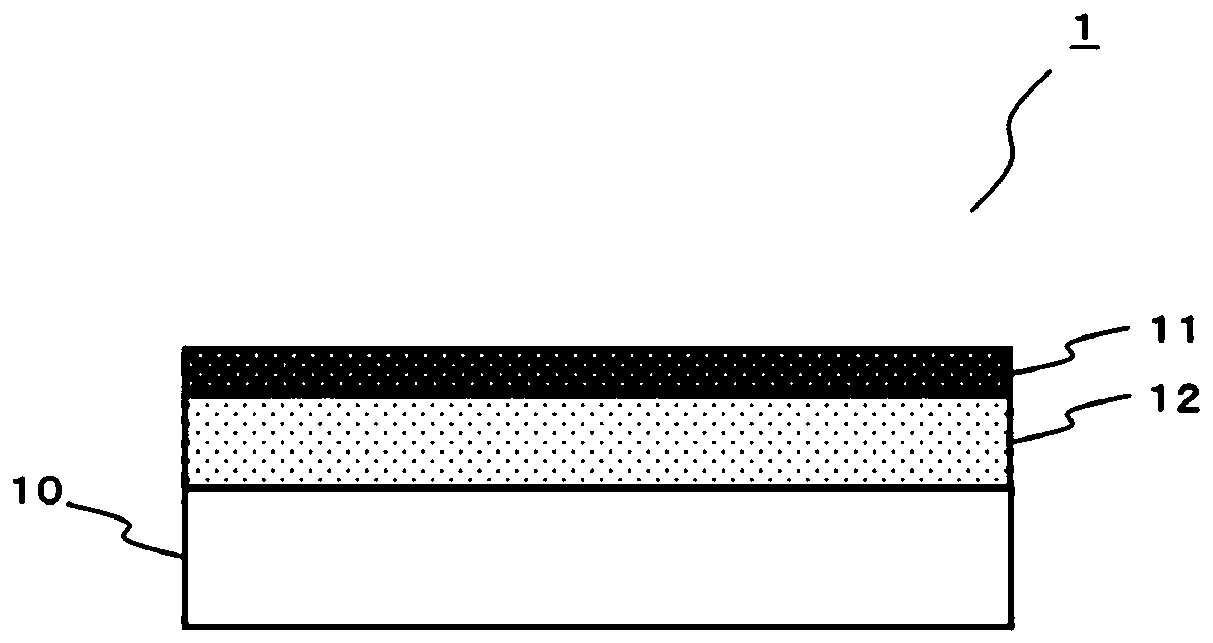

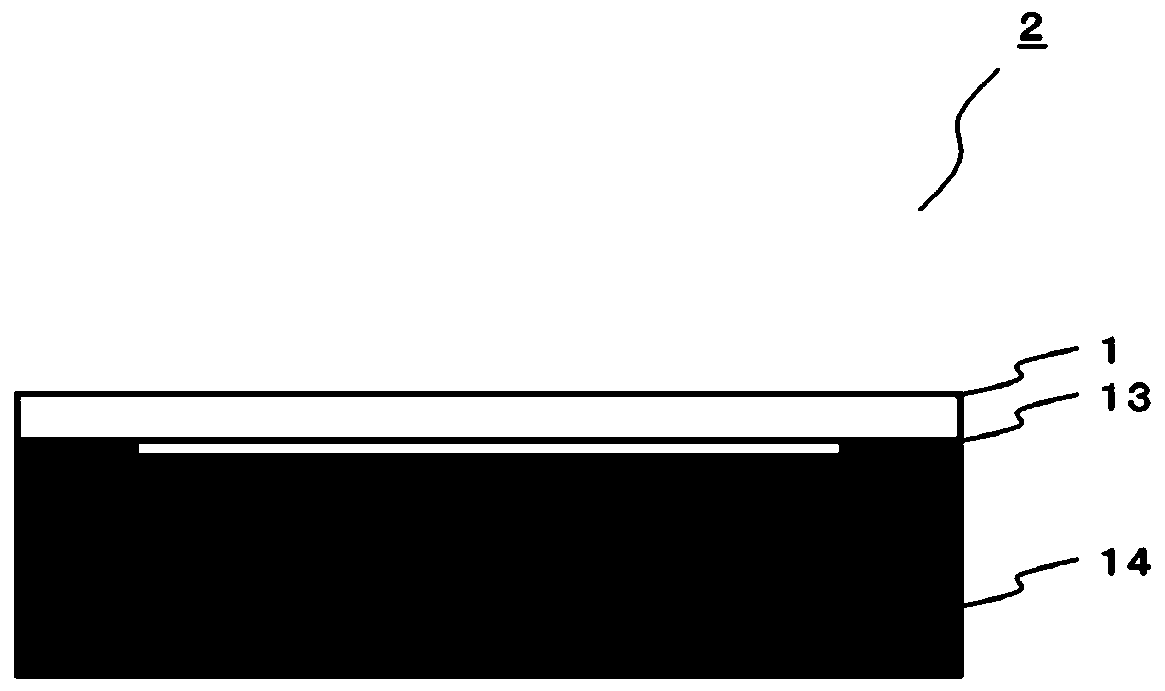

[0179] · Translucent substrate

[0180] As a light-transmitting substrate, a polyethylene terephthalate (PET) film (Tetoron KEL86W, Teijin Dupont film Co., Ltd. manufacture).

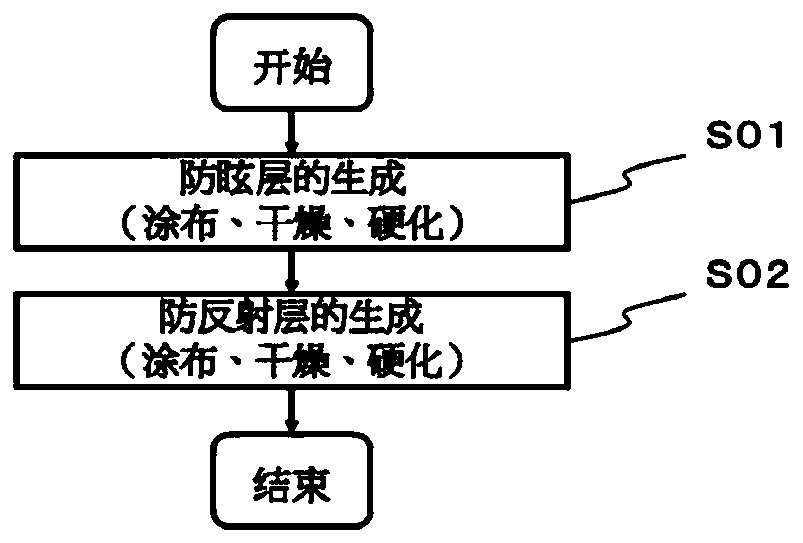

[0181] · Formation of anti-glare layer

[0182] Using a bar coater, the photocurable resin composition (coating solution) A is coated on the base material so that the average film thickness after drying becomes 4 μm to 5 μm, and then the coating is carried out in an oven at a temperature of 85° C. 2 minutes to dry. Thereafter, using a high-pressure mercury lamp, the irradiation dose was 300mJ / cm 2 Photocuring is performed to form an anti-glare layer.

[0183] It is difficult to measure the refractive index of a layer containing fine particles having a particle diameter exceeding 100 nm by the method described in this specification. Since the resin of the anti-glare layer has a refractive index of 1.52 only at 589 nm, the refractive index of silica fine particles is 1.46, and the refractive index of...

Embodiment 2

[0191] An antiglare layer and an antireflection layer were formed in the same manner as in Example 1, except that the photocurable resin composition (coating liquid) B was used when forming the antiglare layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com