Powerless cross sliding type cutter for with continuous casting small plate bland

A cutting machine and traverse technology, which is applied in the field of small slab cut-to-length cutting of metallurgical steelmaking and continuous casting machines, can solve the problems of short replacement cycle of spare parts, high comprehensive cost of use, difficult equipment maintenance, etc., and reduce the maintenance work intensity. , The effect of reducing the overall production cost and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

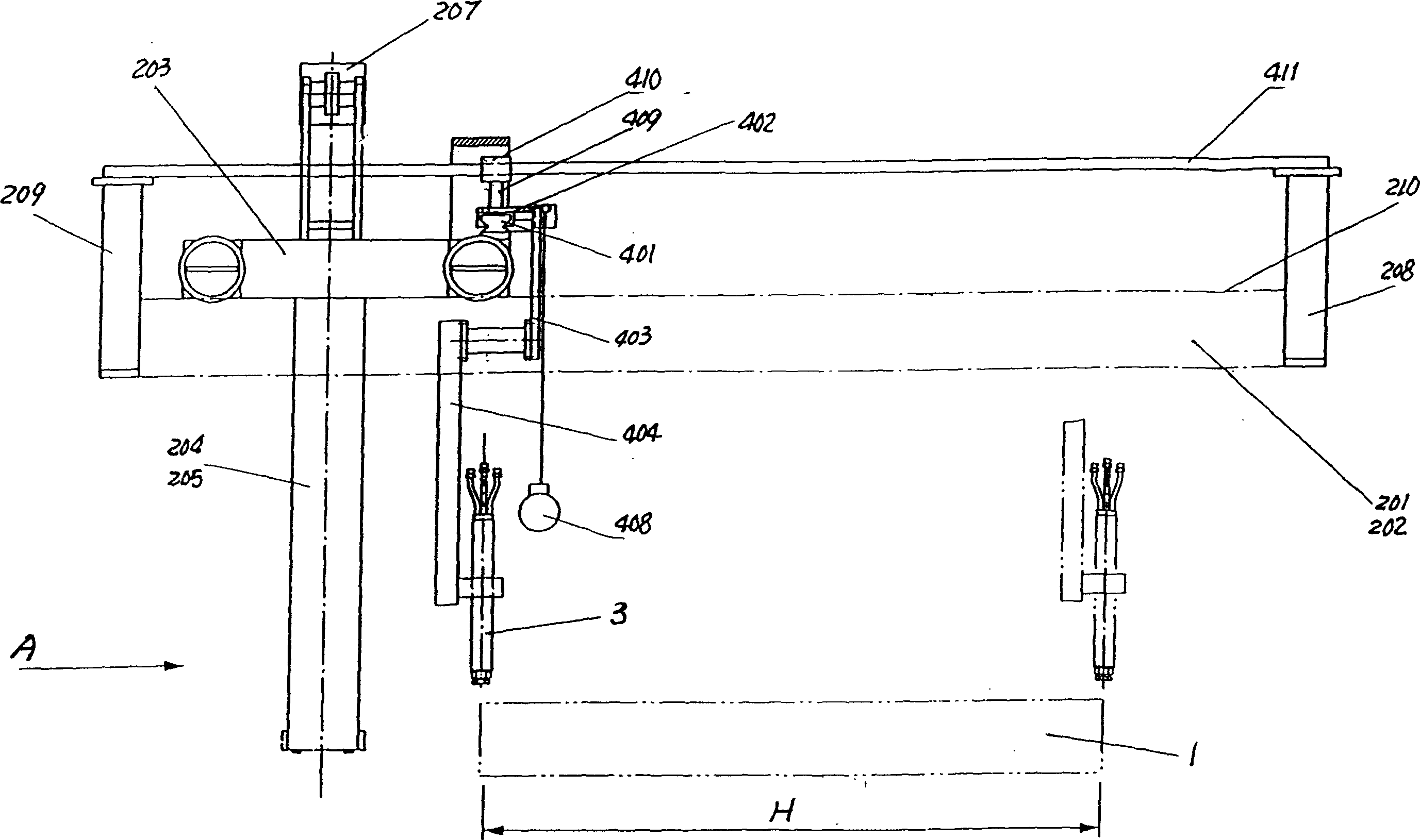

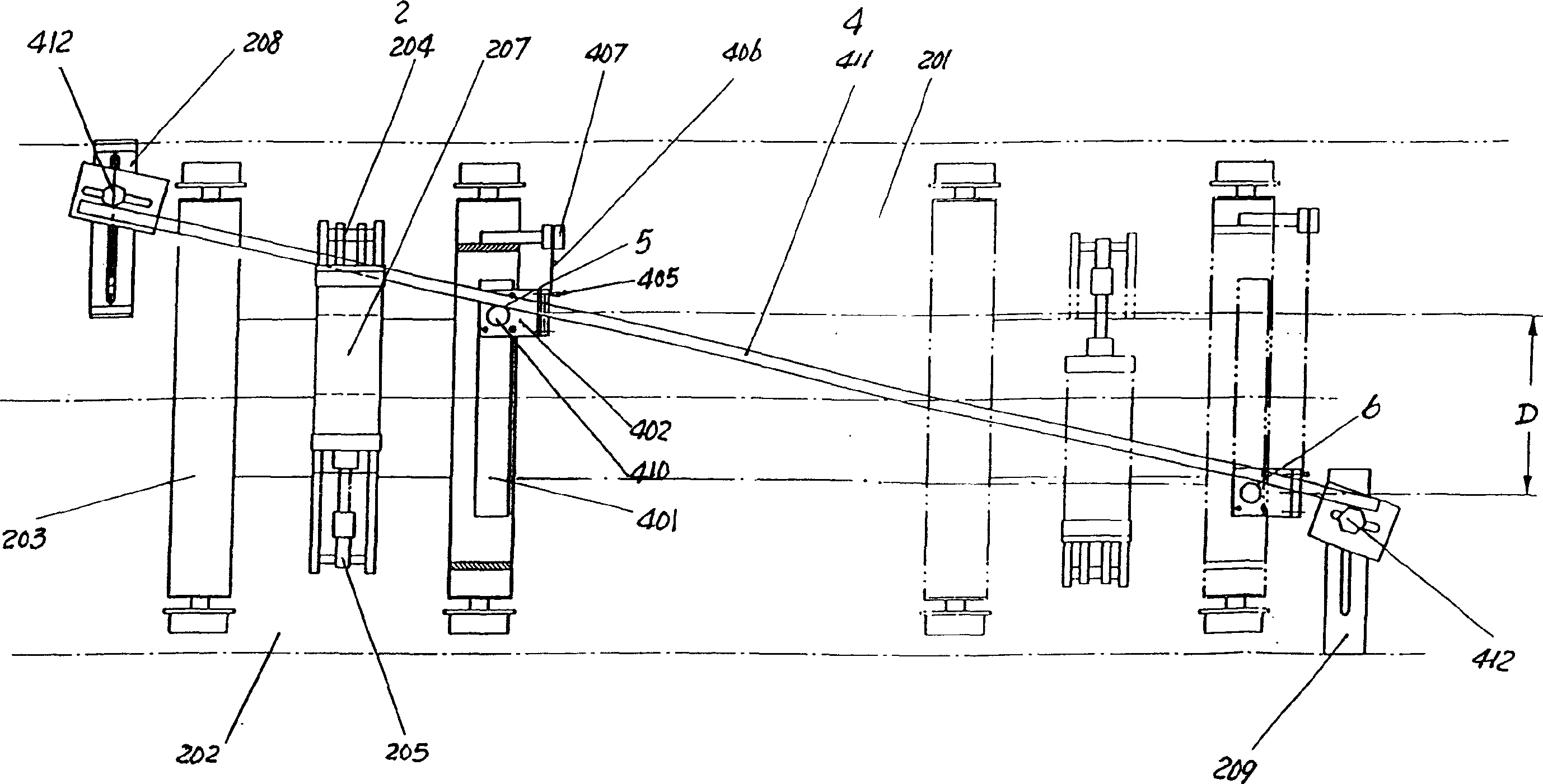

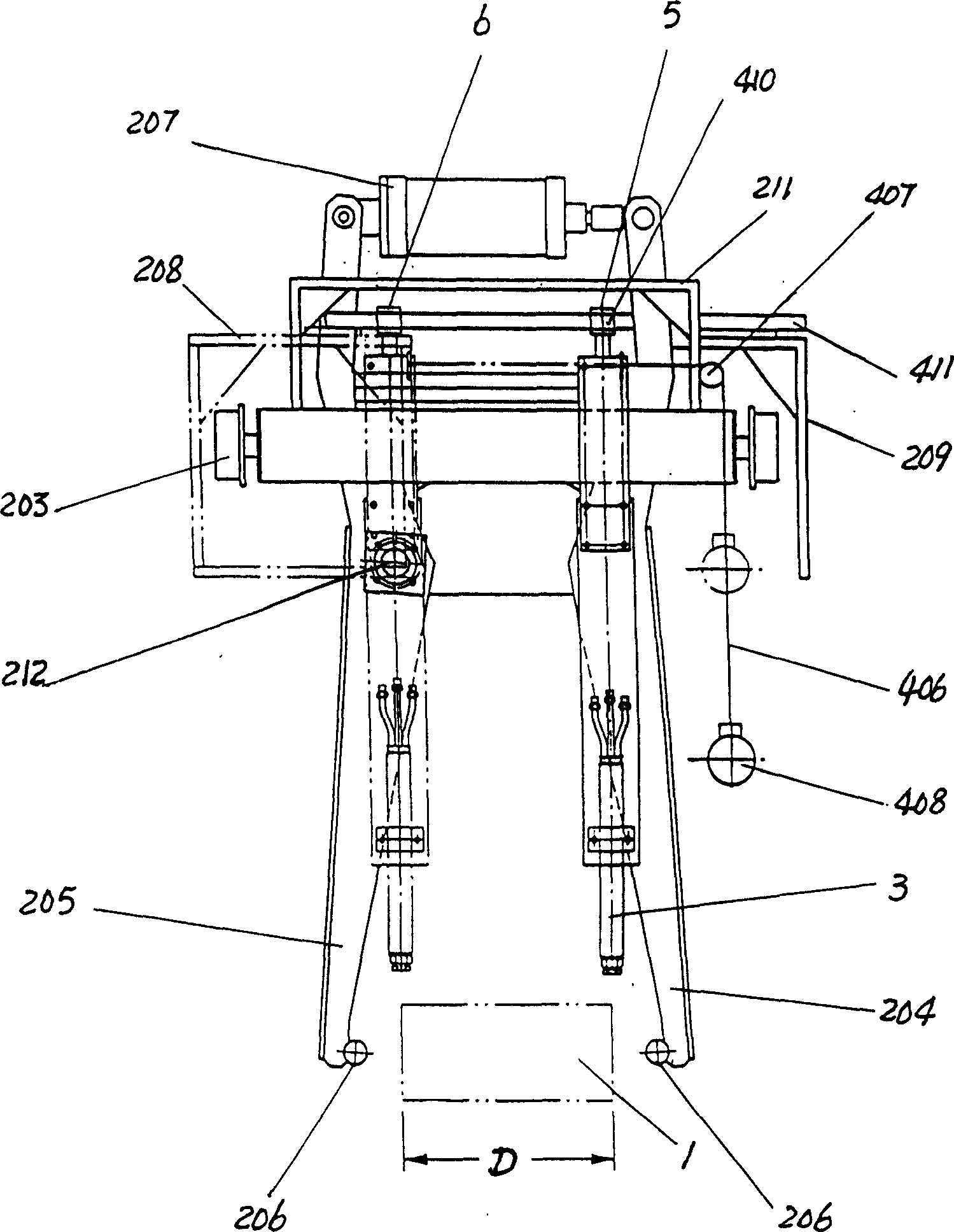

[0059] The technical key of the present invention is: inclined guide rail——produce lateral thrust, traverse guide rail—guidance. There can be many specific implementations about them, and only three are listed here.

[0060] 1. The inclined guide rail adopts alloy steel round bar or plate type, and the traverse guide rail uses linear guide rail finished parts and counterweight device.

[0061] 2. The inclined guide rail adopts the plate type with guide wheel groove in the middle, and the traverse guide rail adopts the plate type with guide wheel groove in the middle. This solution can be completely independently manufactured and processed, and the counterweight device can be eliminated.

[0062] 3. Both the inclined guide rail and the traverse guide rail adopt linear guide rail finished parts. The manufacturing workload of this scheme can be reduced to the minimum, and the counterweight device can also be canceled; the unit cost is relatively high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com