Method of measuring foam rheological behaviour using bleed flou type multipoint pipe viscosimeter

A technology of viscometer and discharge tube, which is applied in the field of measuring foam rheology with a discharge type multi-point tube viscometer, which achieves the effects of short measurement time, stable foam performance and simplified measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

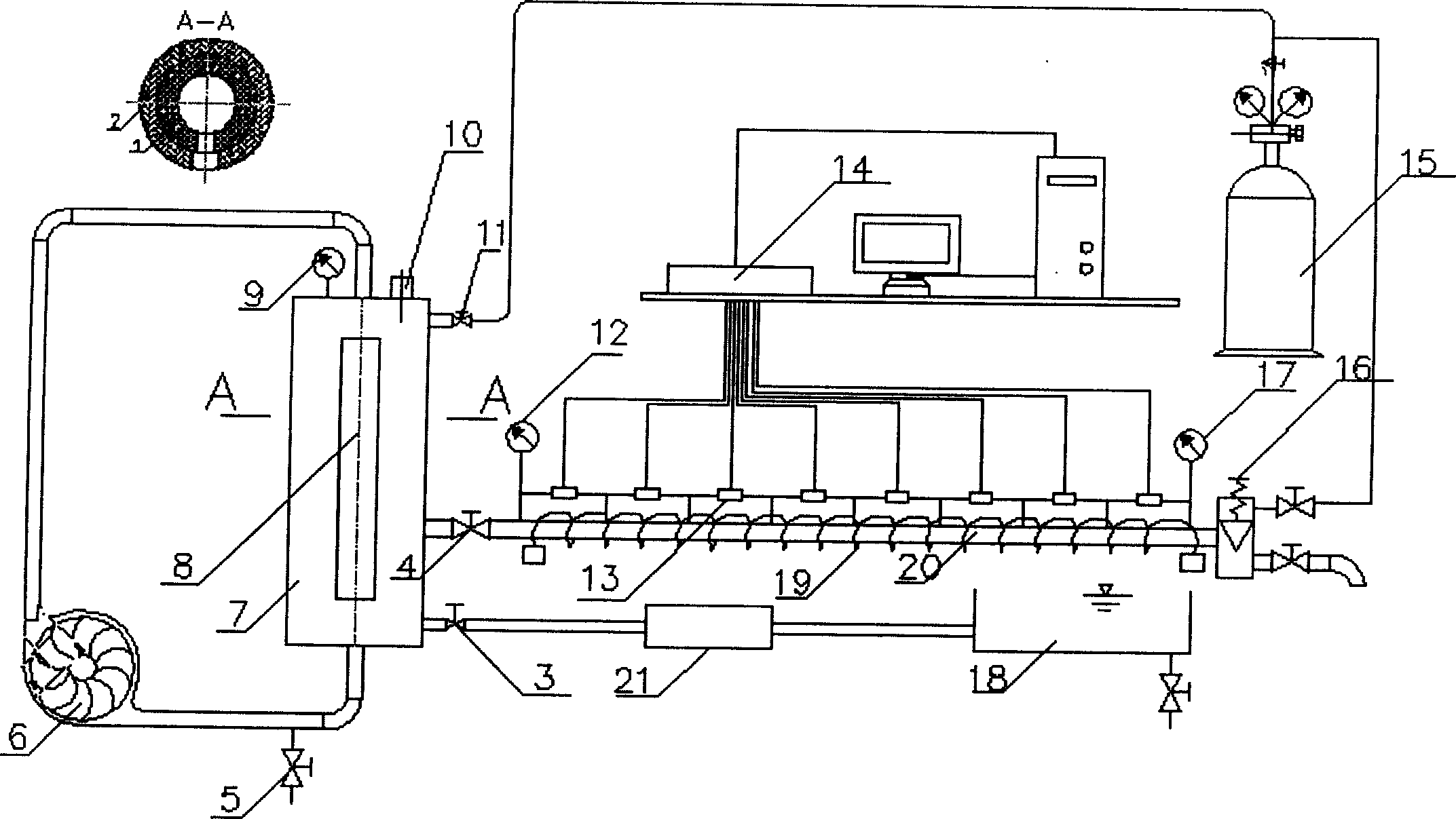

[0011] 1. Inject a predetermined volume of foaming agent into the foaming cylinder 7 through the liquid injection valve 3, and then use the temperature control system 2 to heat to a predetermined temperature and keep the temperature constant;

[0012] 2. Inject the compressed air into the foaming cylinder 7 through the gas injection valve 11 until the predetermined pressure is reached. The gas injection volume can be obtained according to the gas state equation from the injection pressure, temperature and system volume;

[0013] 3. Start the magnetic pump 6 to circulate the foam until the uniform foam is observed from the transparent observation tube 8, then the foaming work is completed. In the subsequent measurement, the magnetic pump 6 is always working, and the foam with eluate in the lower part is drawn out from the bottom, and then foamed after high-speed agitation, and then injected from the top of the cylinder. Stirring up and down in this way keeps the stability of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com