Method for flattening tin ball and fixture

A solder ball and fixture technology, applied in the field of solder ball leveling methods and fixtures, can solve problems such as difficulty, difficulty in setting environmental conditions, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The aforementioned and other technical content, features and effects of the present invention will be clearly understood in the following detailed description of two preferred embodiments with accompanying drawings.

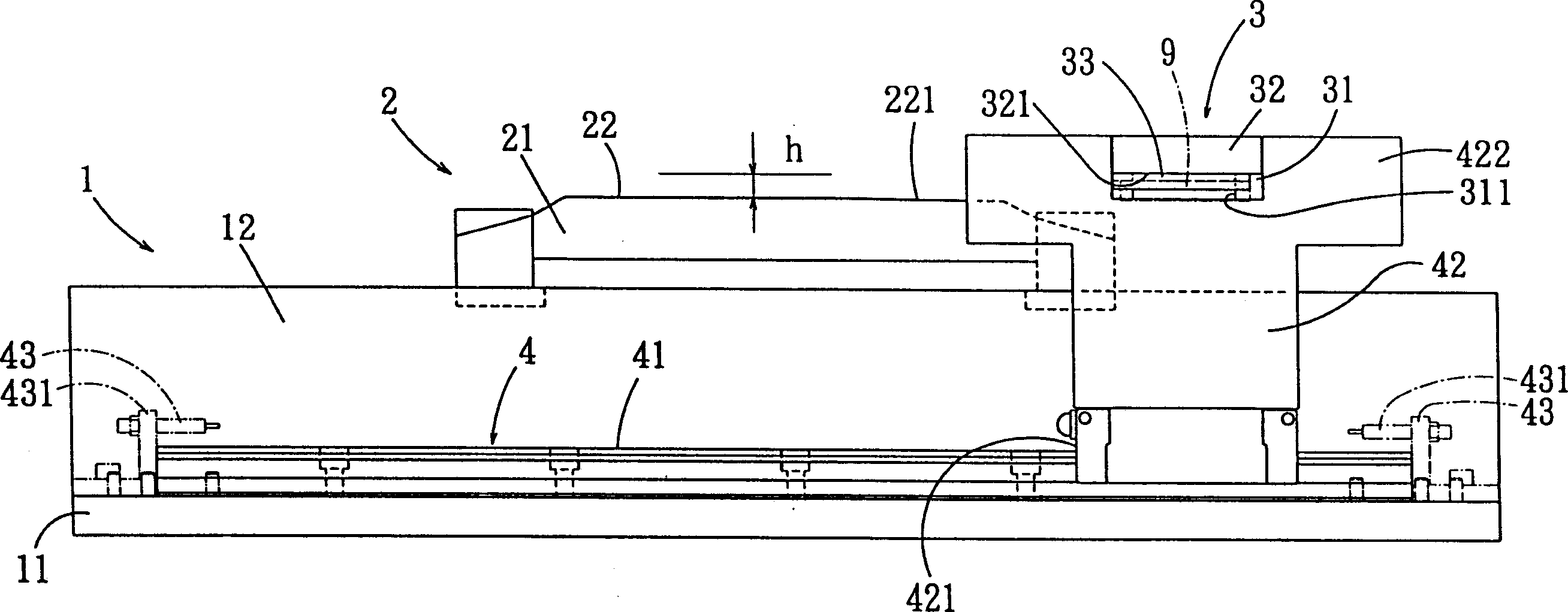

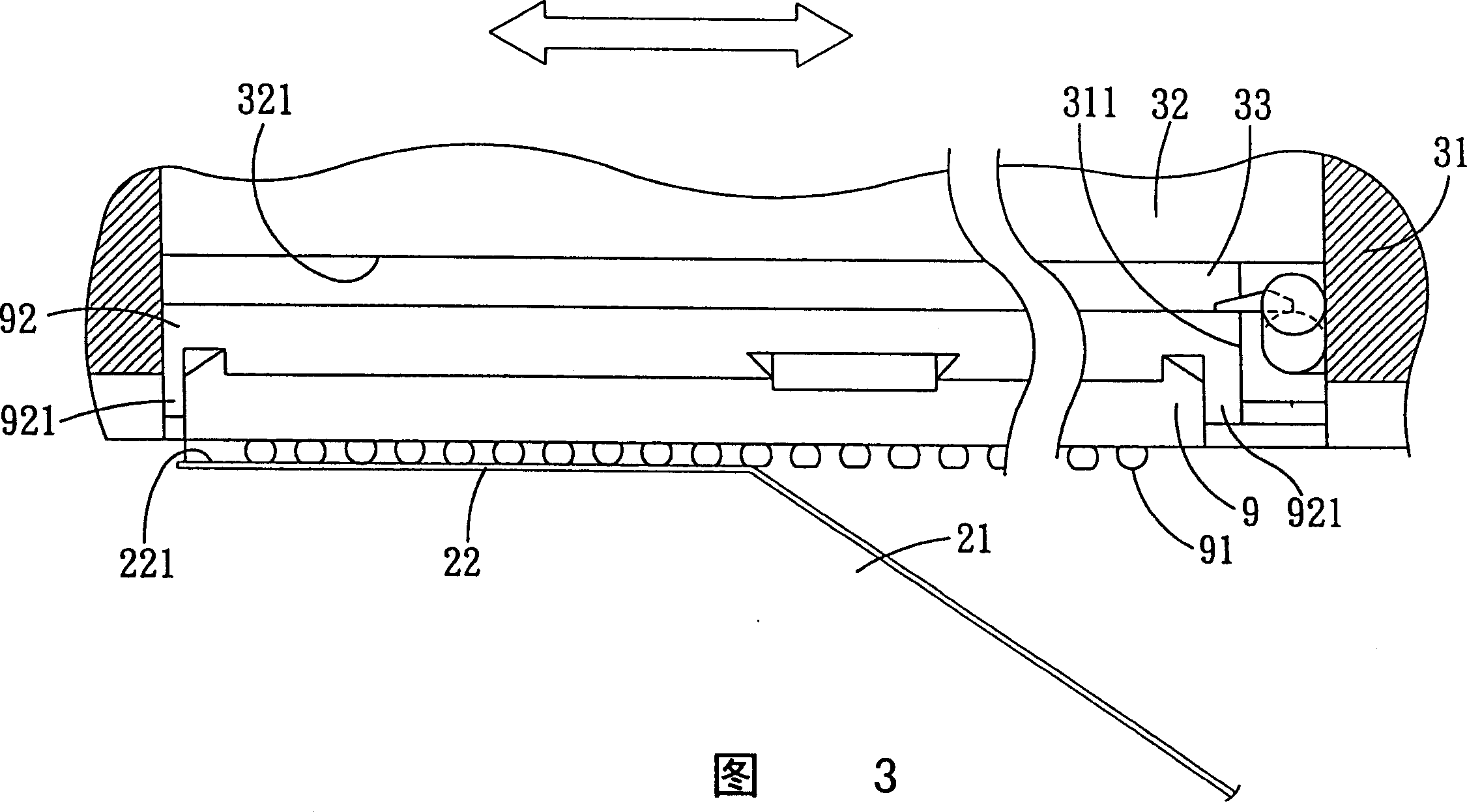

[0011] Such as figure 2 , 3 shows the first preferred embodiment of the solder ball leveling method of the present invention, including a base 1, a leveling device 2 on the base 1, a clamp 3 on the base 1, And a displacement generating device 4 capable of relative displacement of the clamp 3 and the leveling device 2 .

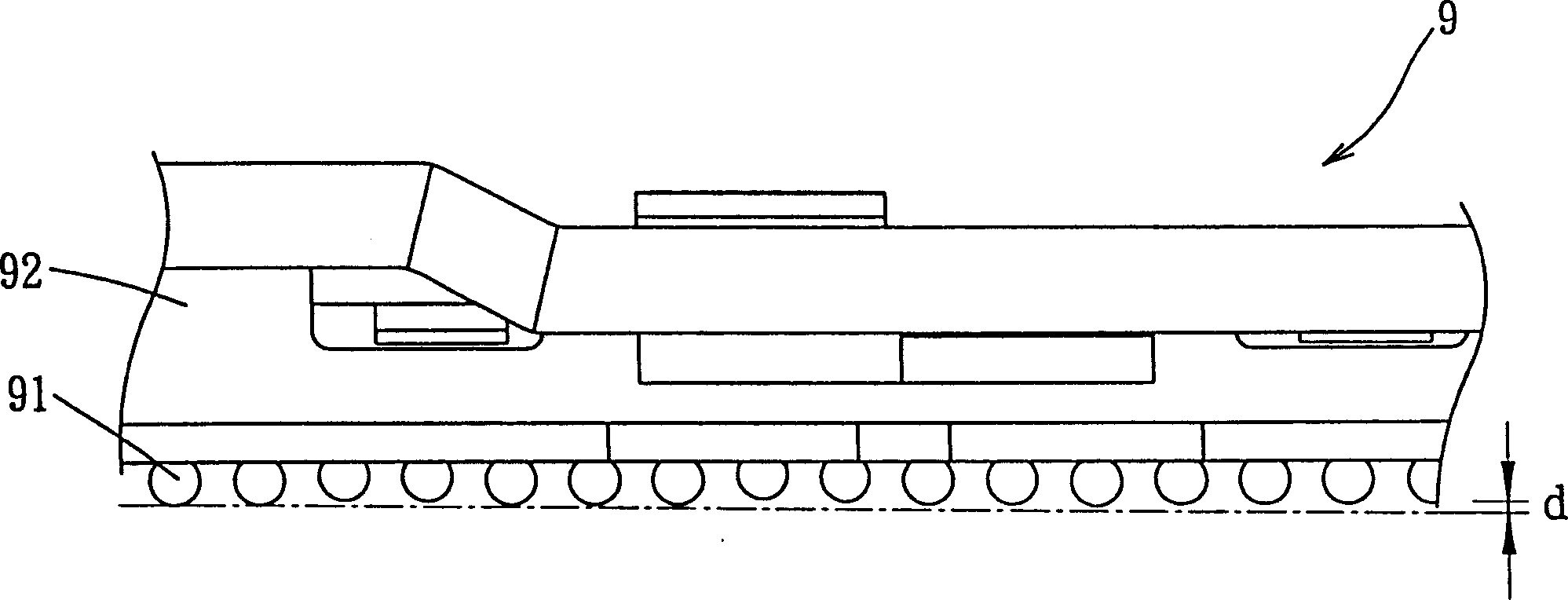

[0012] The base 1 has a bottom plate 11 and an accommodating portion 12 fixed above the bottom plate 11 . The leveling device 2 has a platform 21 erected at the center of the accommodating portion 12, and a rough surface 22 laid on the platform 21. In this preferred embodiment, the material of the rough surface 22 is diamond sandpaper, and the rough surface 22 has The first side 221 facing upwards.

[0013] The displacement generating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com