Oscillating mechanism for a distributor roll of a press

A technology of lateral swinging and friction rollers, which is applied in printing machines, general parts of printing machinery, printing, etc., can solve the problems of multi-structure space, hindering the reduction of the diameter of friction rollers, etc., and achieve the effect of small diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

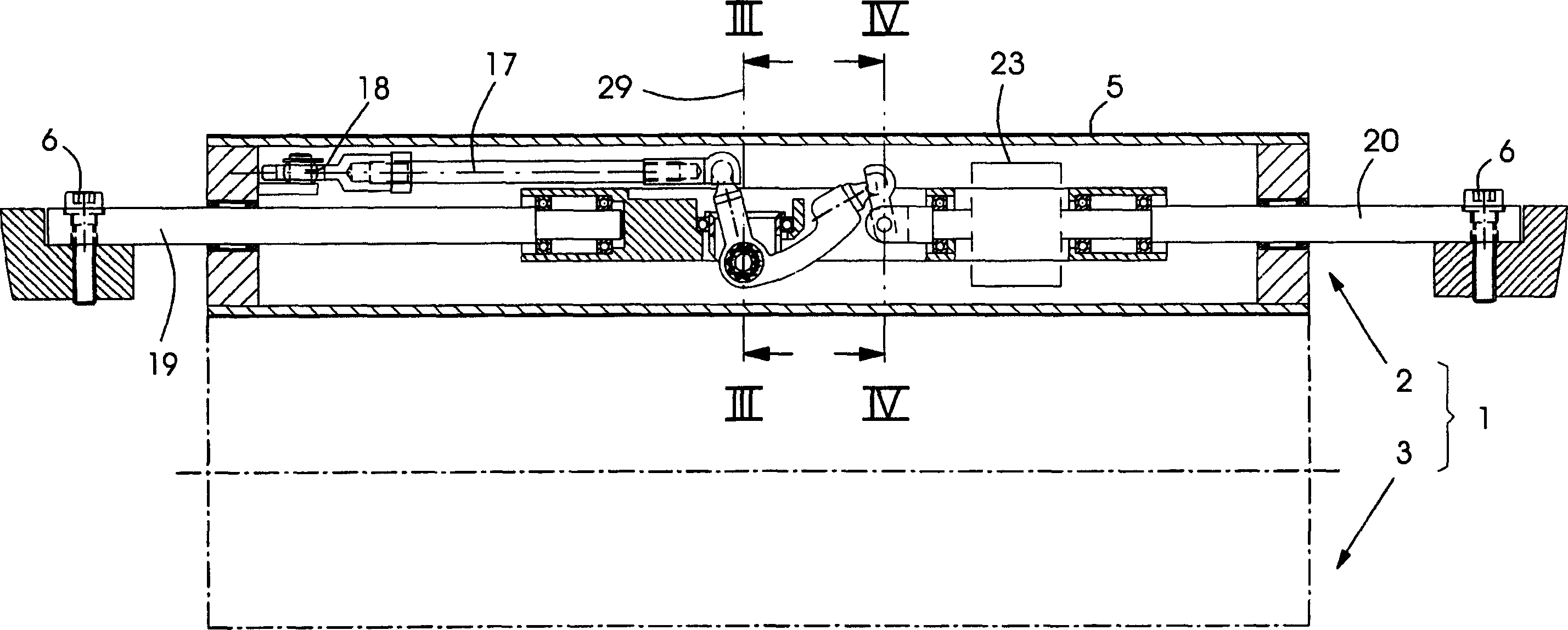

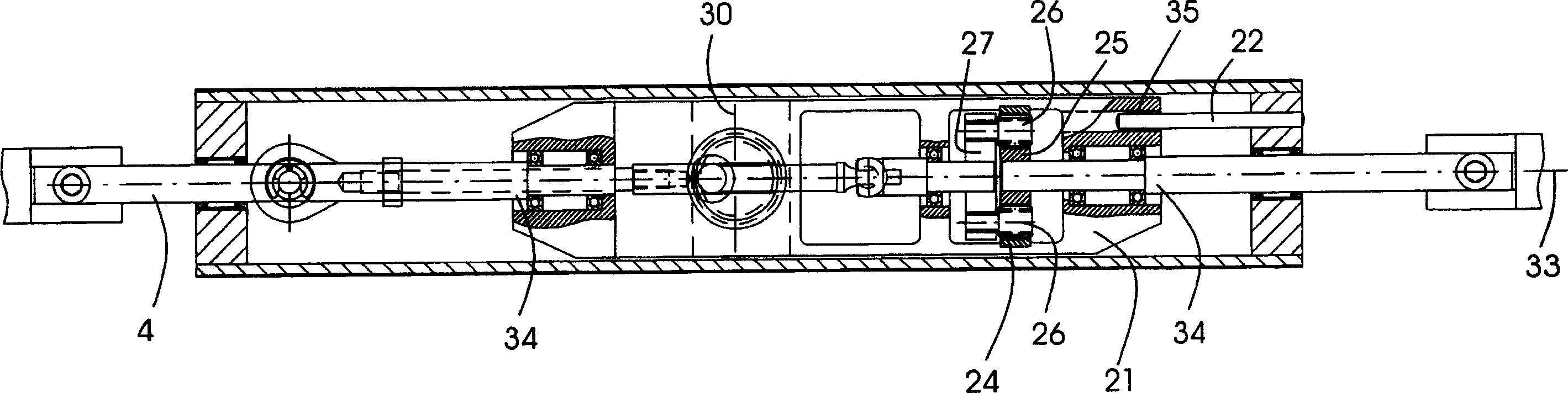

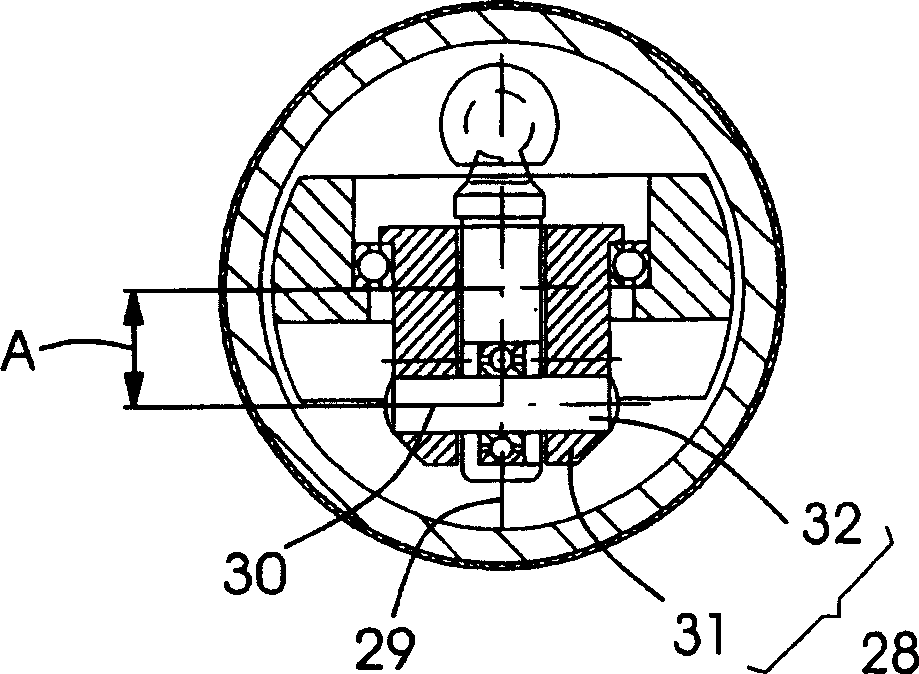

[0025] exist Figures 1 to 8 A printing press 1 for offset lithography is shown in detail in the figure. The printing machine 1 comprises a friction roller 2 and a further roller 3 which is rotationally driven by friction between the rollers, so that no gear pair connecting the friction roller 2 to the further roller 3 is required. exist figure 1 The other roller 3 is marked with a dotted line in . The rubbing roller 2 comprises a multi-section roller shaft 4 and a hollow roller body 5, which is rotatable on the roller shaft 4 around the roller shaft and movable along the roller shaft. The roller shaft 4 does not rotate and is locked in a roller lock 6 designed as a quick lock. To the extent that the friction roller 2 needs to be temporarily removed from the printing press 1 for maintenance purposes, it is advantageous that the roller lock 6 can be released and locked quickly.

[0026] A crank transmission device 7 using space transmission technology is arranged inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com