Vortex compressor

A scroll compressor and volute technology, applied in the field of scroll compressors, can solve problems such as performance degradation, insufficient compression, and increased indicated power, and achieve the effects of improving efficiency, preventing the increase of indicated power, and preventing internal leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is based on Figure 1 to Figure 6 Examples of the present invention will be described.

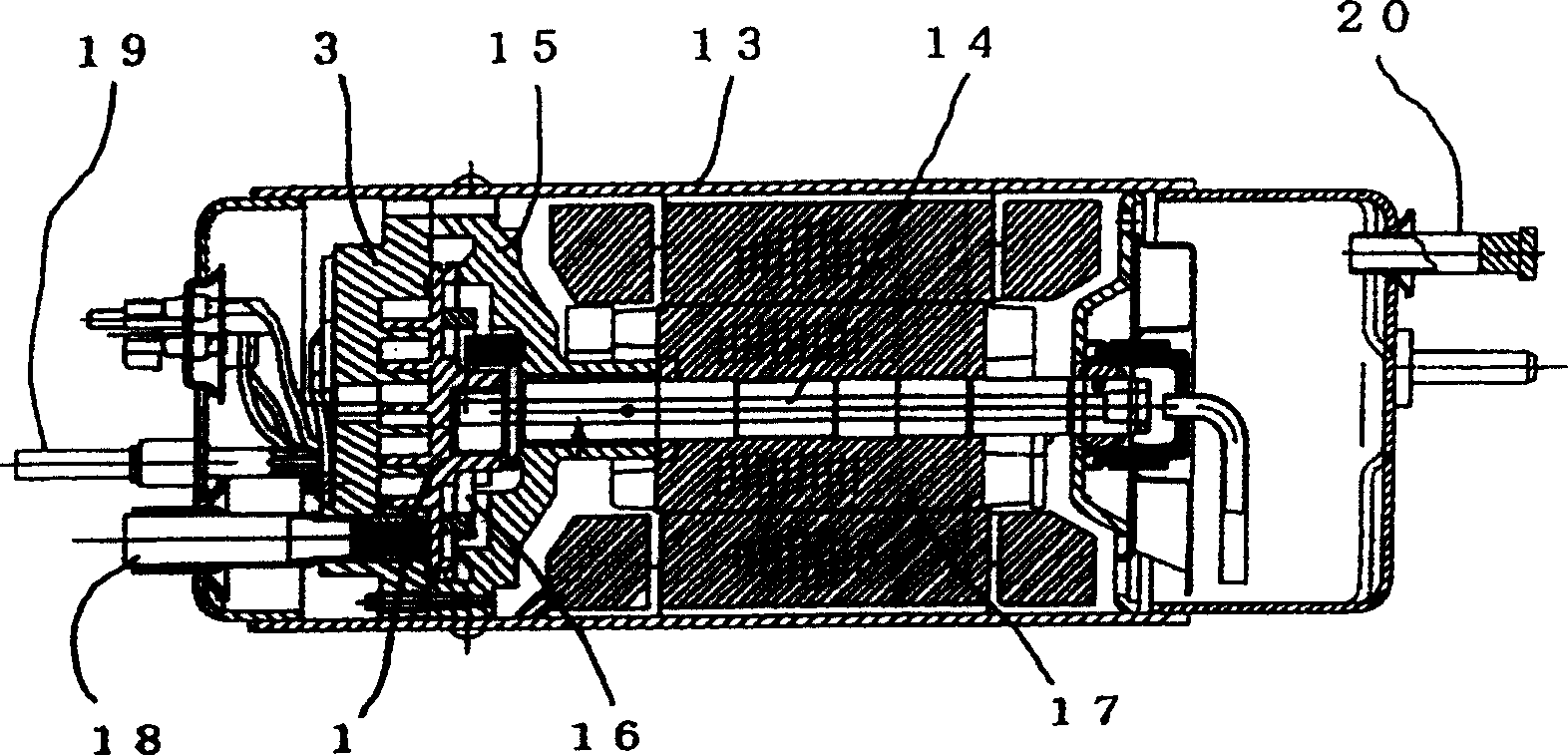

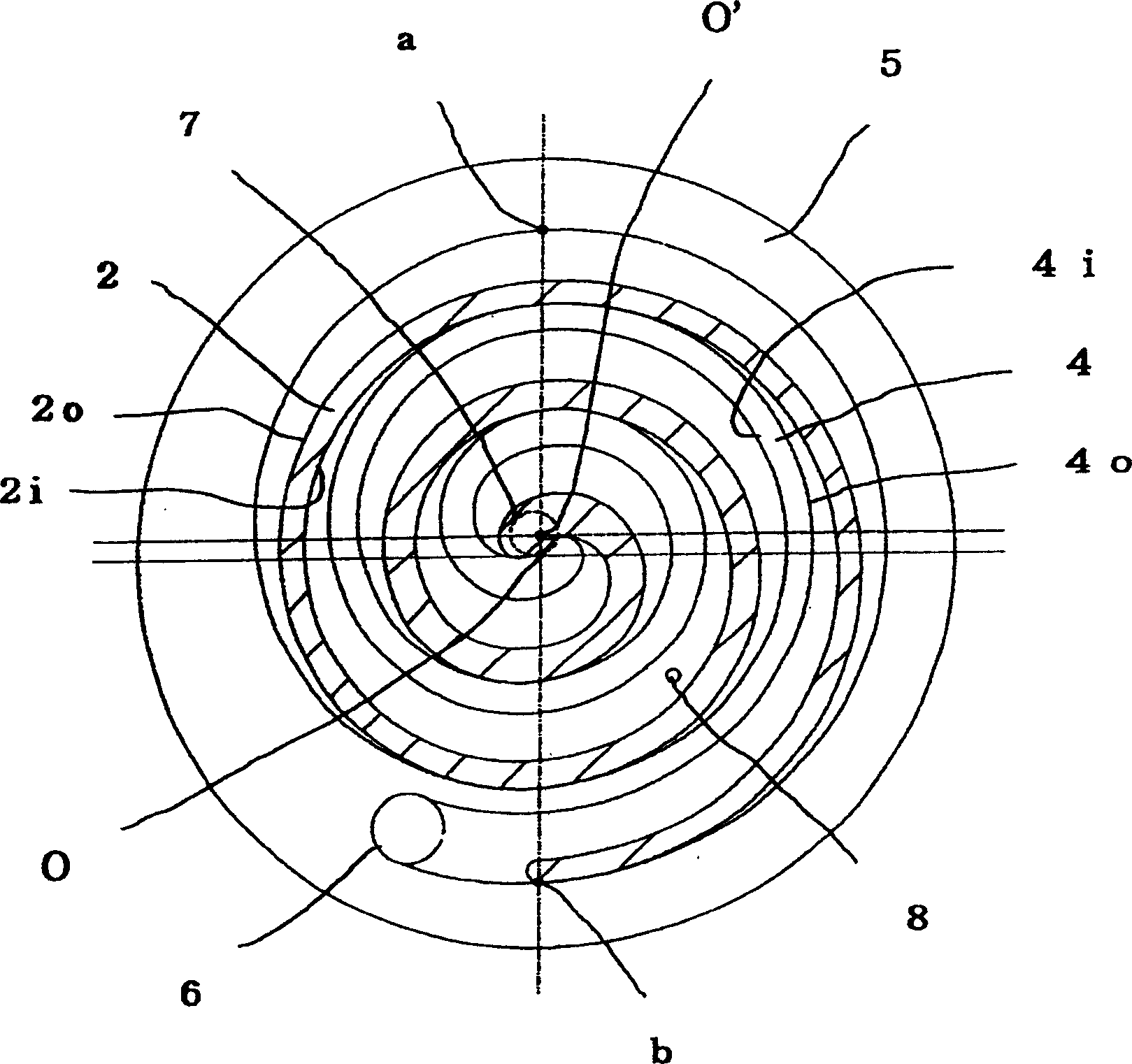

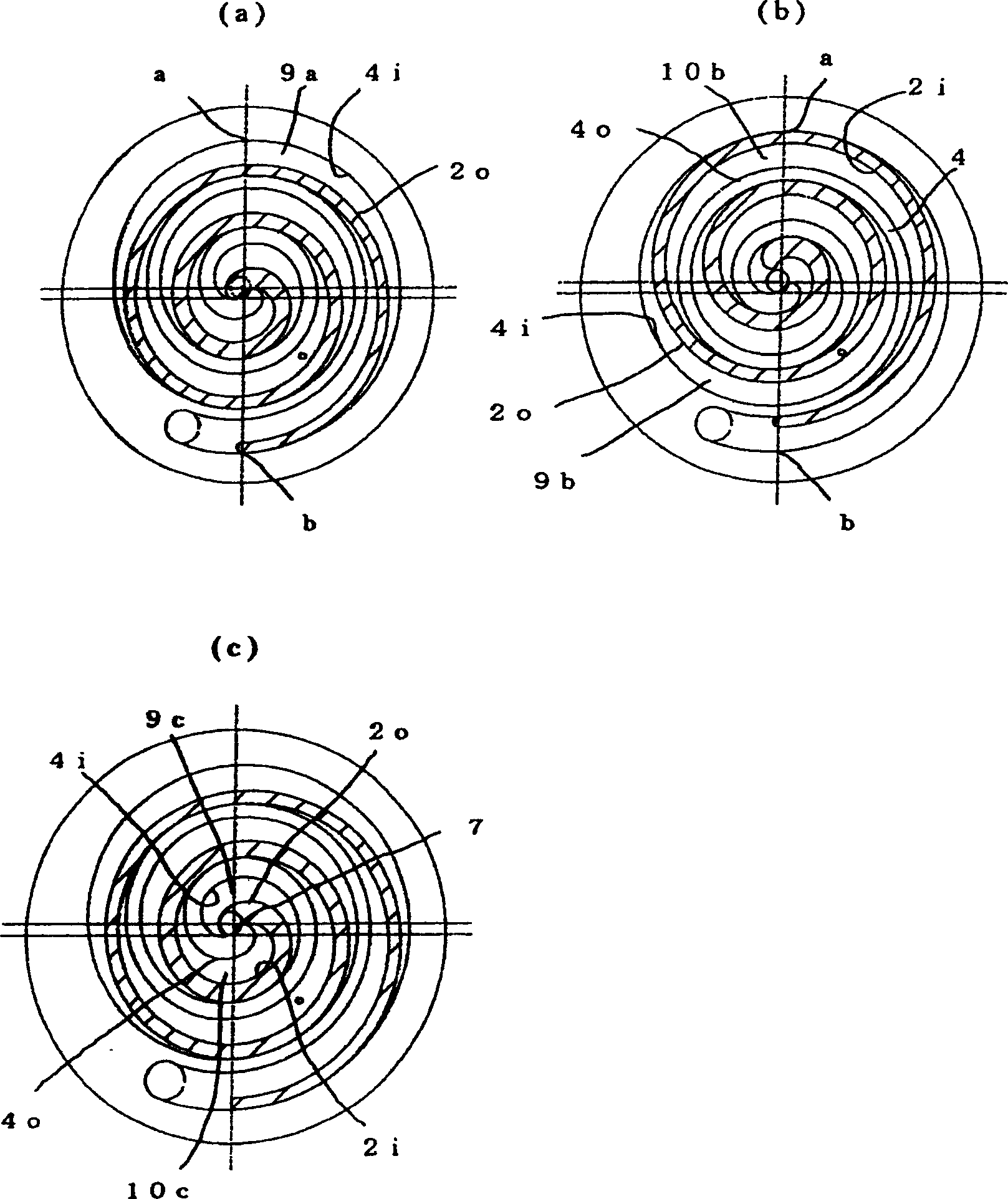

[0027] figure 1 A longitudinal sectional view showing a scroll compressor according to an embodiment of the present invention. The scroll compressor 13 has a rotating scroll 1 and a fixed scroll 3, a crank shaft 14 that rotates the rotating scroll 1, a bracket 15 that supports the crank shaft 14, and an Oldham ring 16 that allows the orbiting motion of the rotating scroll 1 and prevents rotation. , the motor 17 that drives the crankshaft 14 . The helicoids of the two volutes 1 and 3 have a basic vortex curve which is a reference curve defining the helical shape as an algebraic helical curve. By making the deflection angle of the spiral body of the fixed scroll 3 approximately 180 degrees larger than the deflection angle of the orbiting scroll 1, the rotation end position of the fixed scroll 3 is extended beyond the same position as the rotation end position of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com