Real time automatic cleaning method and apparatus for ink-jet head of digital ink-jet printer

A digital inkjet and automatic cleaning technology, which is applied in printing and other fields, can solve the problems of unreasonable control of cleaning operation time, inability to realize automatic real-time operation, unreasonable devices, etc., and achieve the effect of convenient real-time cleaning, simple structure and reasonable steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

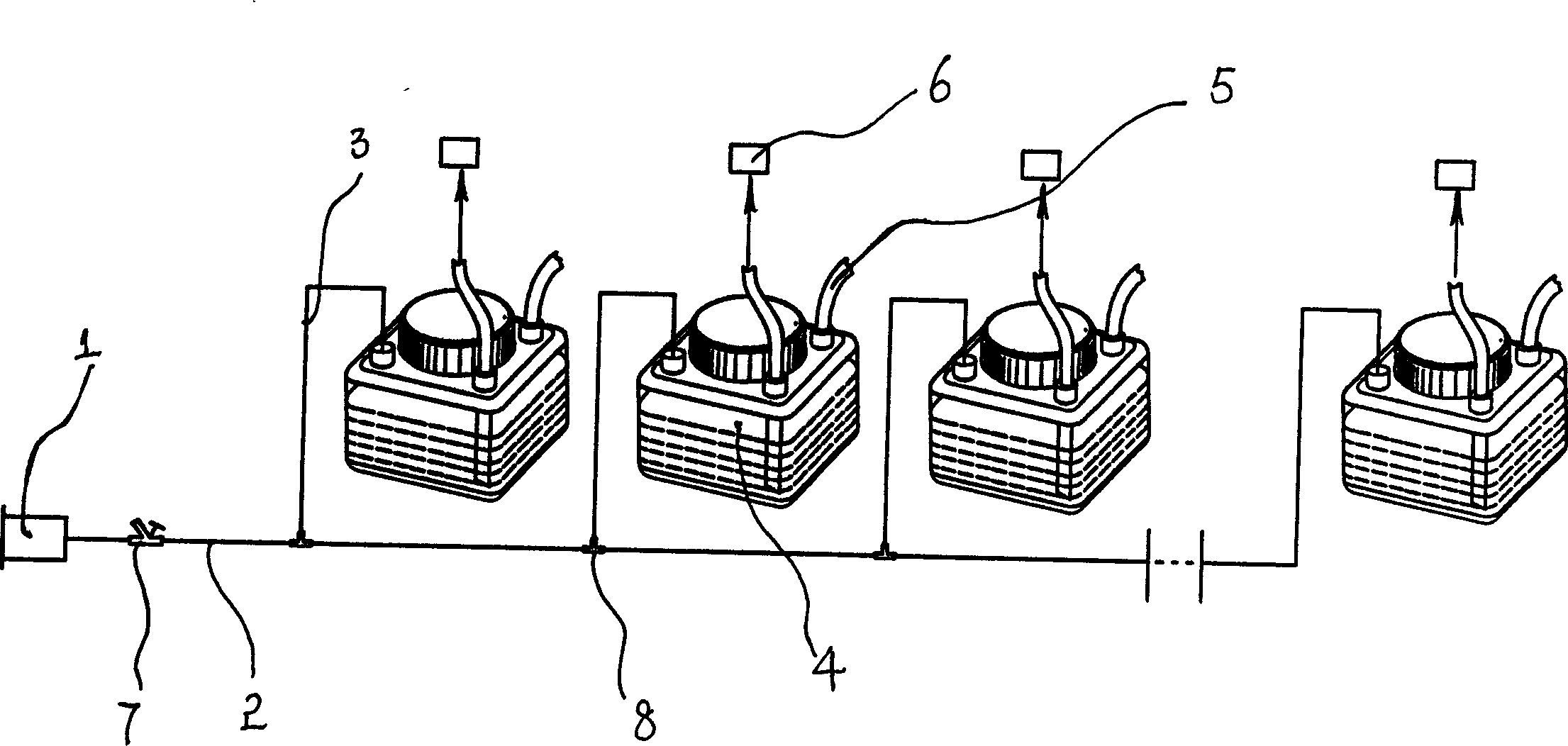

[0025] Embodiment 1: as figure 1 , the ink in the main ink bottle of each color passes through the liquid flow pump and the ink filter, and injects the ink of this color into the ink supply bottle 4 of each color as required. The compressed air of the cleaning device of the present invention is produced by the air pump 1, injected into the main air circuit 2 after being filtered, and after passing through the valve body 7 on the main air circuit 2, the air flows through several three-way valves 8 to connect with each branch air circuit respectively. 3 connected to each other, then enter the ink supply bottles 4 of various colors, and be connected to each nozzle 6 by the ink filling pipeline 5 inserted into the bottom of each ink supply bottle 4. The valve body 7 is a three-way valve controlled by a relay, and one foot thereof is directly connected with the outside world. The plane where the nozzles of the spray head 6 are located is higher than the liquid level of the ink in ...

Embodiment 2

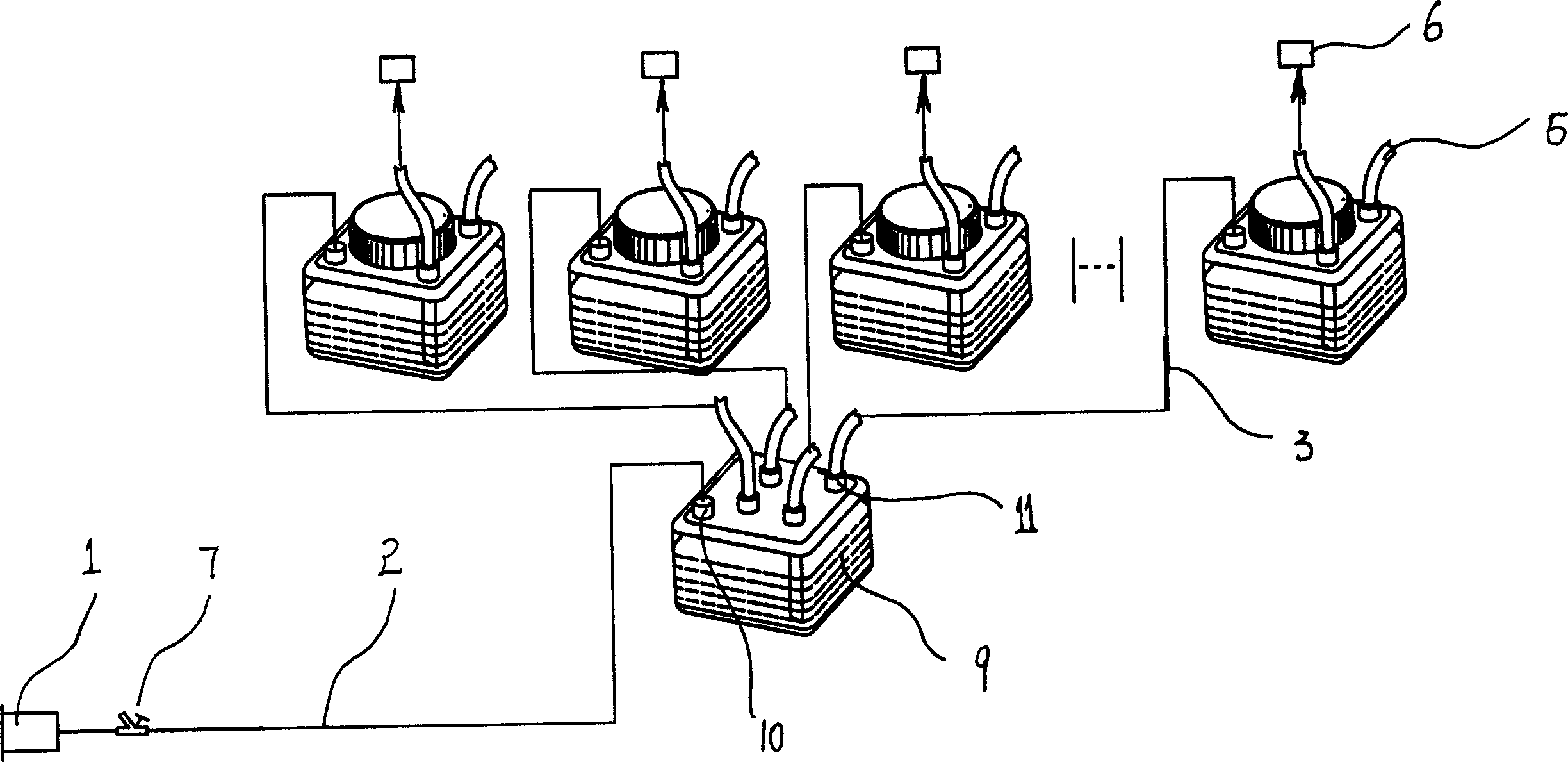

[0027] Embodiment 2: as figure 2 , the main gas path here is not connected to each branch gas path through a tee pipe, but a buffer chamber 9 is provided on the main gas path 2, and the buffer chamber 9 is connected to each branch gas path; the buffer chamber An air inlet 10 and an air outlet 11 connected to the branch airway 3 are arranged on the 9 . The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com