Intelligent type heat pump water heater

A heat pump water heater, an intelligent technology, is applied in the directions of fluid heaters, household heating, heating methods, etc., can solve the problems of insufficient preheating time, unstable performance of the heat pump water heater, etc., and achieves long service life, low cost, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

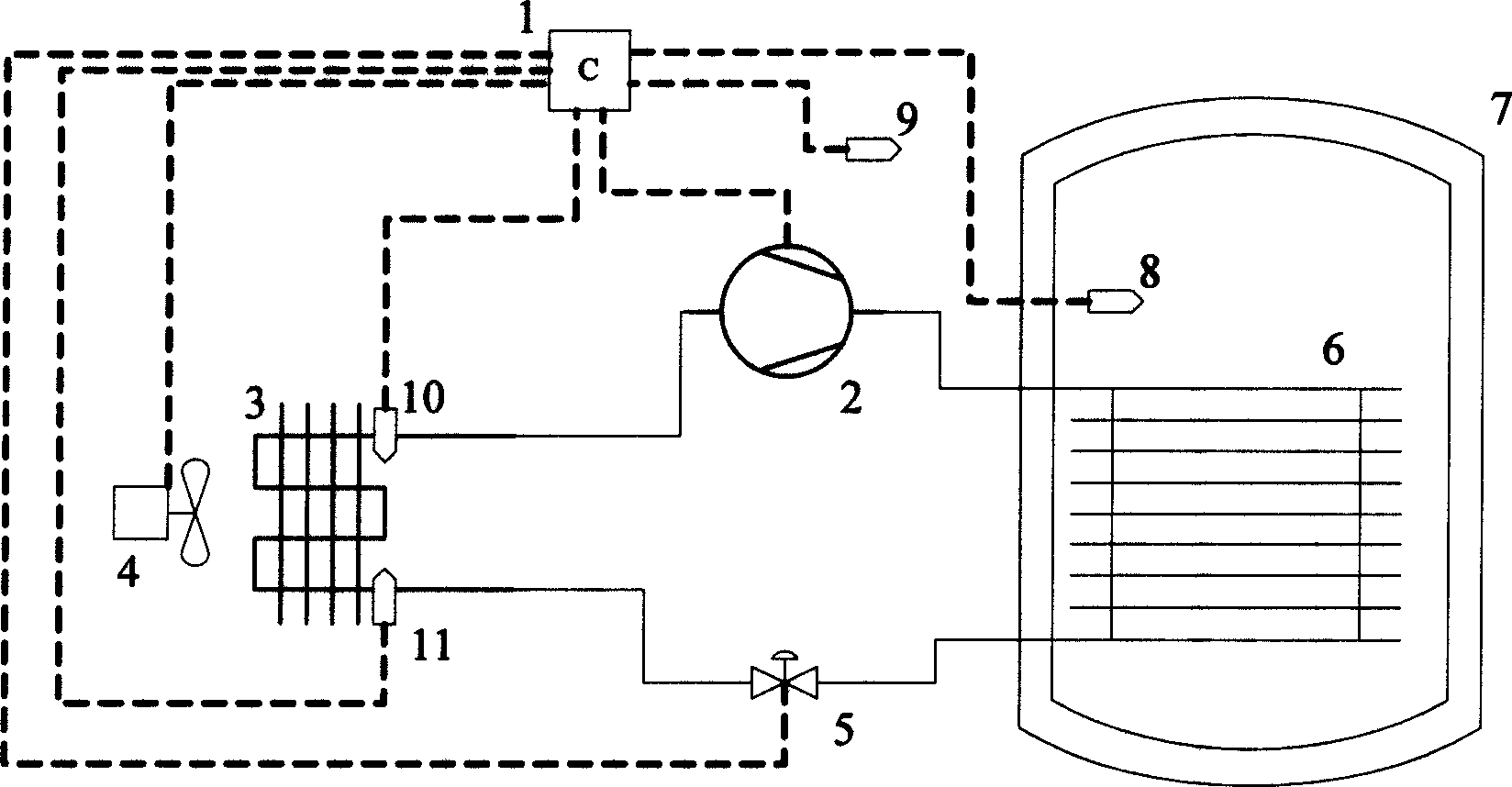

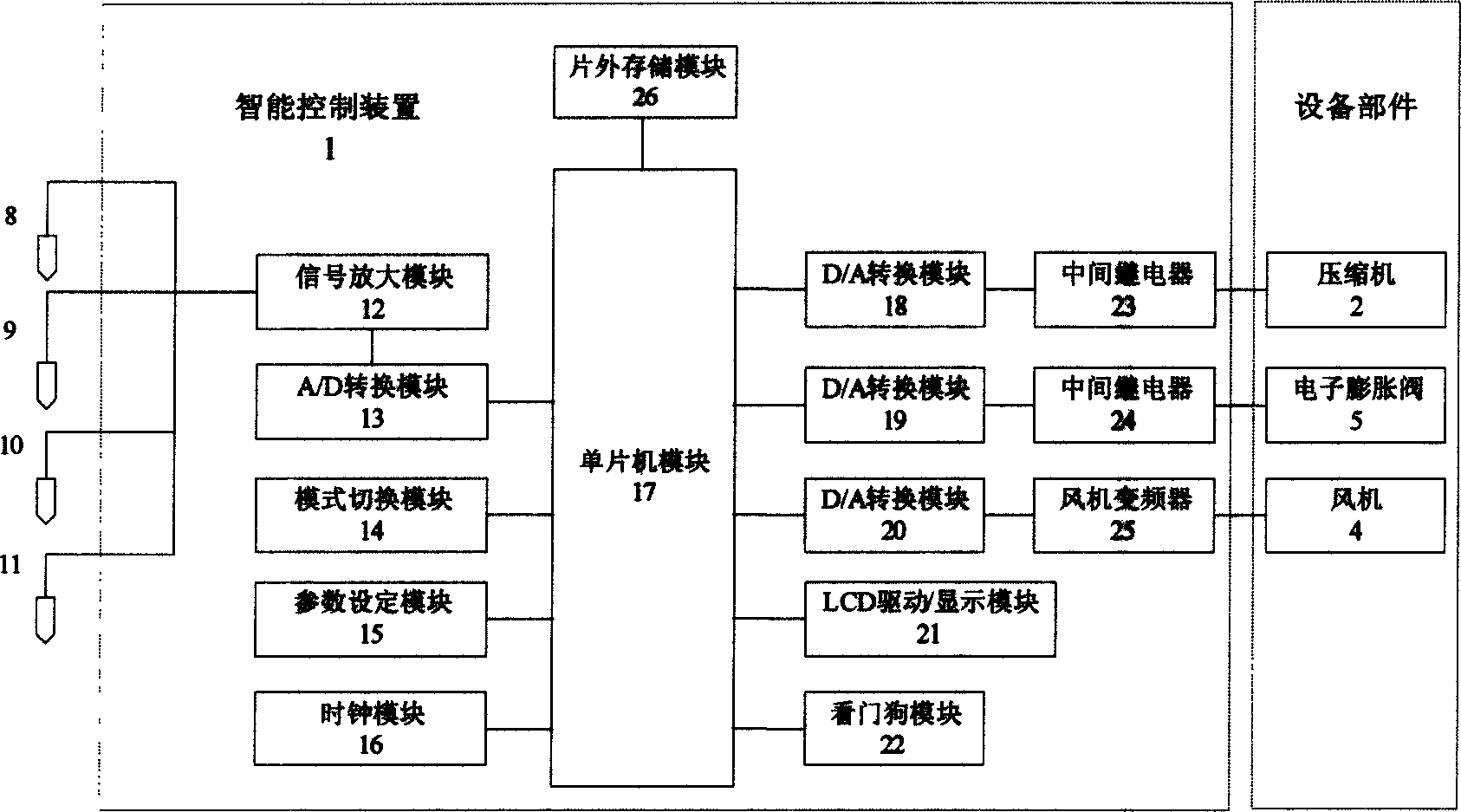

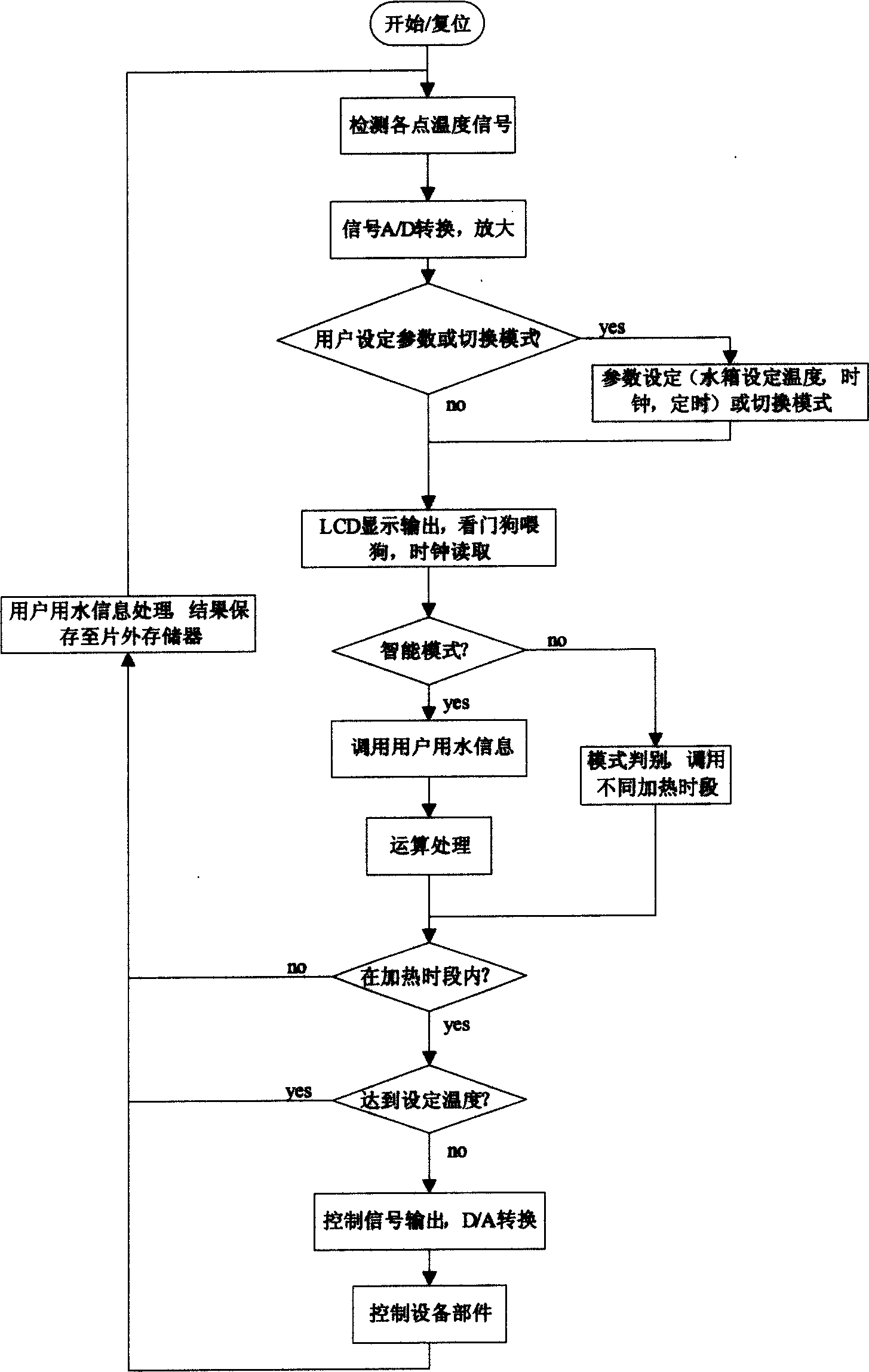

[0017] Overall structure of the present invention is as figure 1 As shown, the intelligent heat pump water heater consists of a compressor 2, an evaporation coil 3, a fan 4, an electronic expansion valve 5, a condensing coil 6 and a living water tank 7 to form a conventional heat pump water heater system, and its operating status is regulated by an intelligent control device 1. The water tank temperature sensor 8 is set in the middle of the living water tank 7 to monitor the temperature of hot water in the tank, the ambient temperature sensor 9 is set in the outdoor space where the evaporation coil 3 is located, to monitor the ambient temperature, the evaporator inlet temperature sensor 11 and the evaporator outlet The temperature sensors 10 are respectively arranged on the inlet and outlet pipes of the evaporating coil 3 to monitor the degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com