Heat exchanger, heat exchanger manufacturing method, and air conditioner

A technology for heat exchangers and manufacturing methods, applied to heat exchange equipment, heating methods, air conditioning systems, etc., capable of solving problems such as processing through holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0035] Hereinafter, a first embodiment of the present invention will be described with reference to the drawings.

[0036] (1) Heat exchanger structure

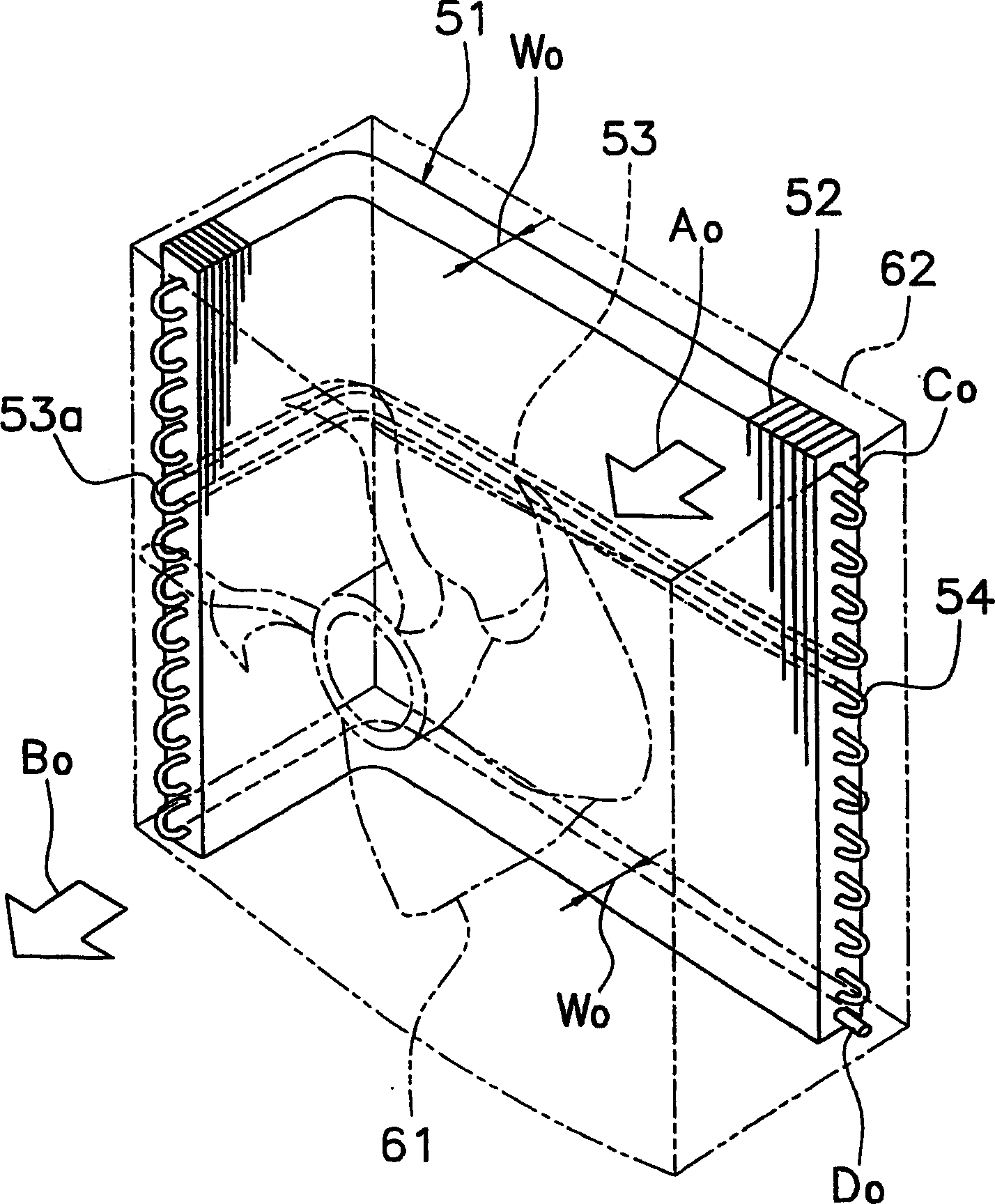

[0037] Figure 4 It is a schematic perspective view showing the outdoor unit of the air conditioner using the heat exchanger 1 according to the first embodiment of the present invention. The heat exchanger 1 is L-shaped, and its purpose is to match the air flow formed by the propeller blower 11 from the back side of the outdoor unit casing 12 to the front side (see arrow A). 1 and B 1 ) for heat exchange to evaporate or condense the refrigerant flowing inside the tube of the heat transfer tube.

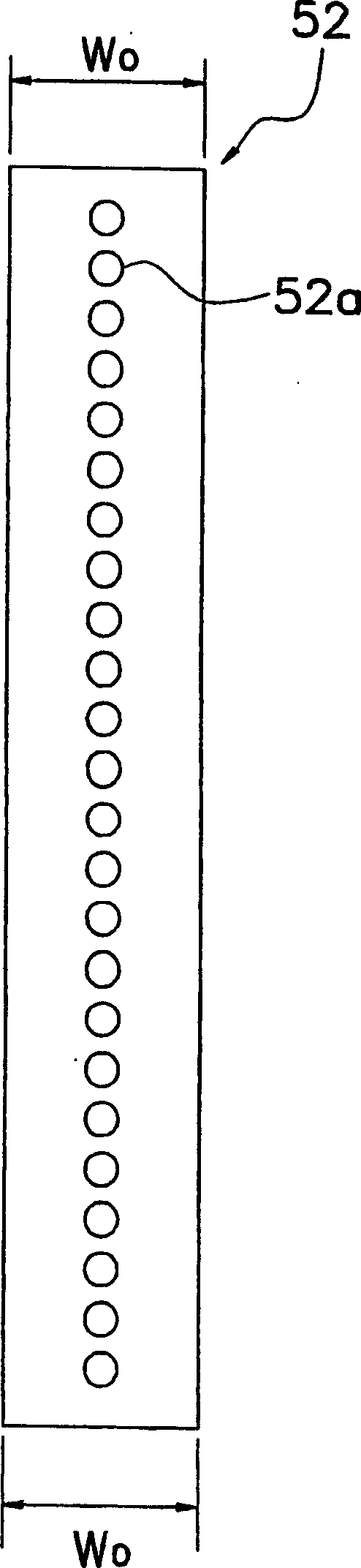

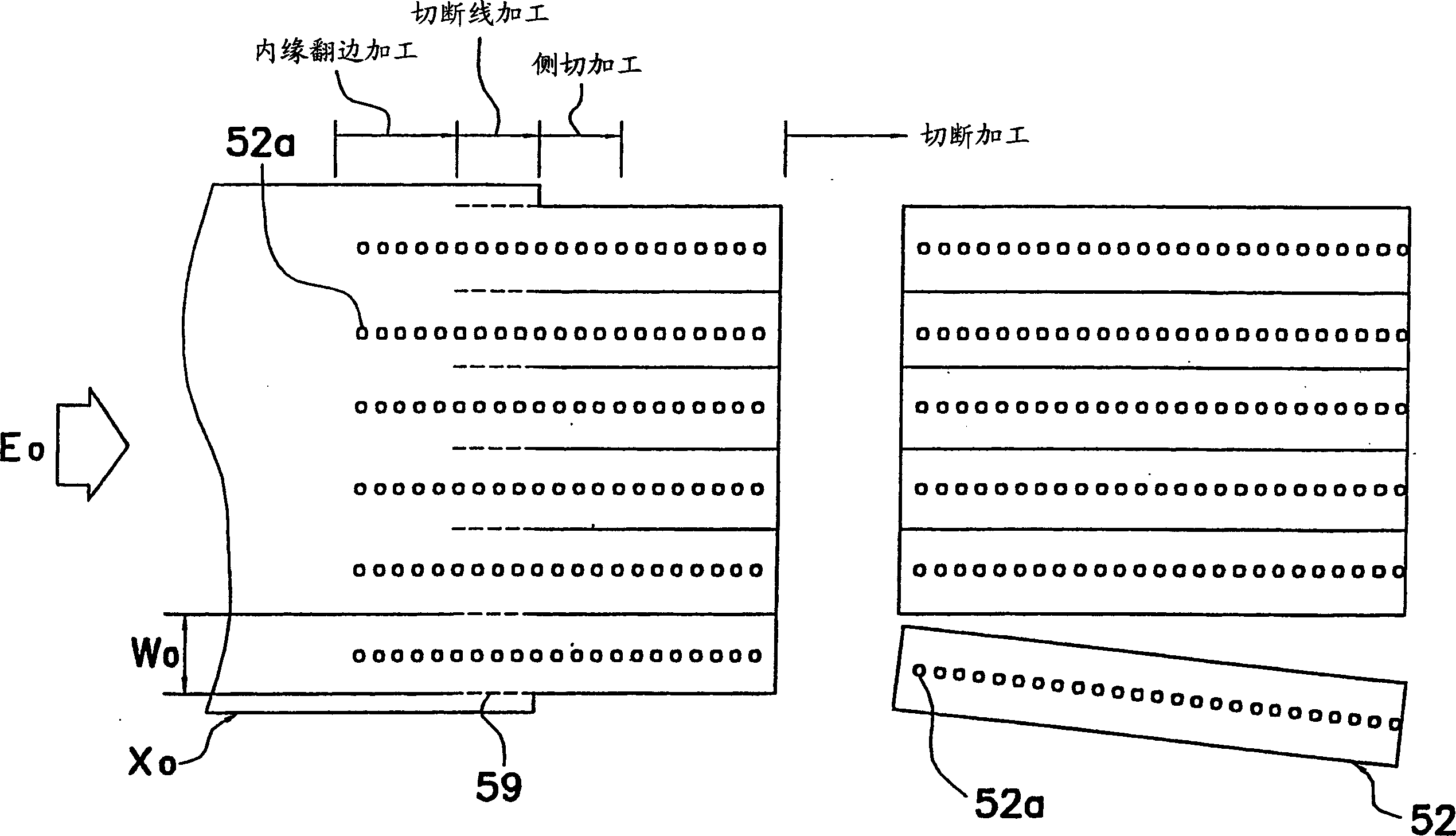

[0038] The heat exchanger 1 includes: a plurality of fins 2 arranged at predetermined intervals in the plate thickness direction; and a plurality of heat transfer tubes 3 attached to penetrate the plurality of fins 2 in the plate thickness direction. Heat sink 2 as Figure 4 and Figure 5 As shown, it has its width from one sid...

no. 2 approach

[0062] In the first embodiment, if Figure 5 As shown, the width of the heat sink 2 is continuously changed, but it can also be as Figure 7 As shown in the heat sink 22, the width is formed stepwise from one side to the other side by W 1 shrink to W 2 shape. Also in this case, the same effect as that of the first embodiment can be obtained.

no. 3 approach

[0064] In the first and second embodiments, such as Figure 5 and Figure 7 As shown, the heat sink 2 is formed in a symmetrical shape with respect to the center (centre) of the width direction of the heat sink, but it may also be Figure 8 Like the heat sink 32 shown, when two heat sinks are arranged in the heat sink width direction, it becomes a rectangular shape. In this case, compared with the first and second embodiments, the material loss of the plate-shaped blank can be further reduced.

[0065] (Other implementations)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com