Large-scale seaweed cell or tissue reactor pre-culturing system

A cell culture and reactor technology, applied in the field of pre-culture systems, can solve the problems of dispersion, one-sidedness, and singleness, and achieve the effects of reliable experimental data, reduction of time and cycle, and reduction of system errors and human errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

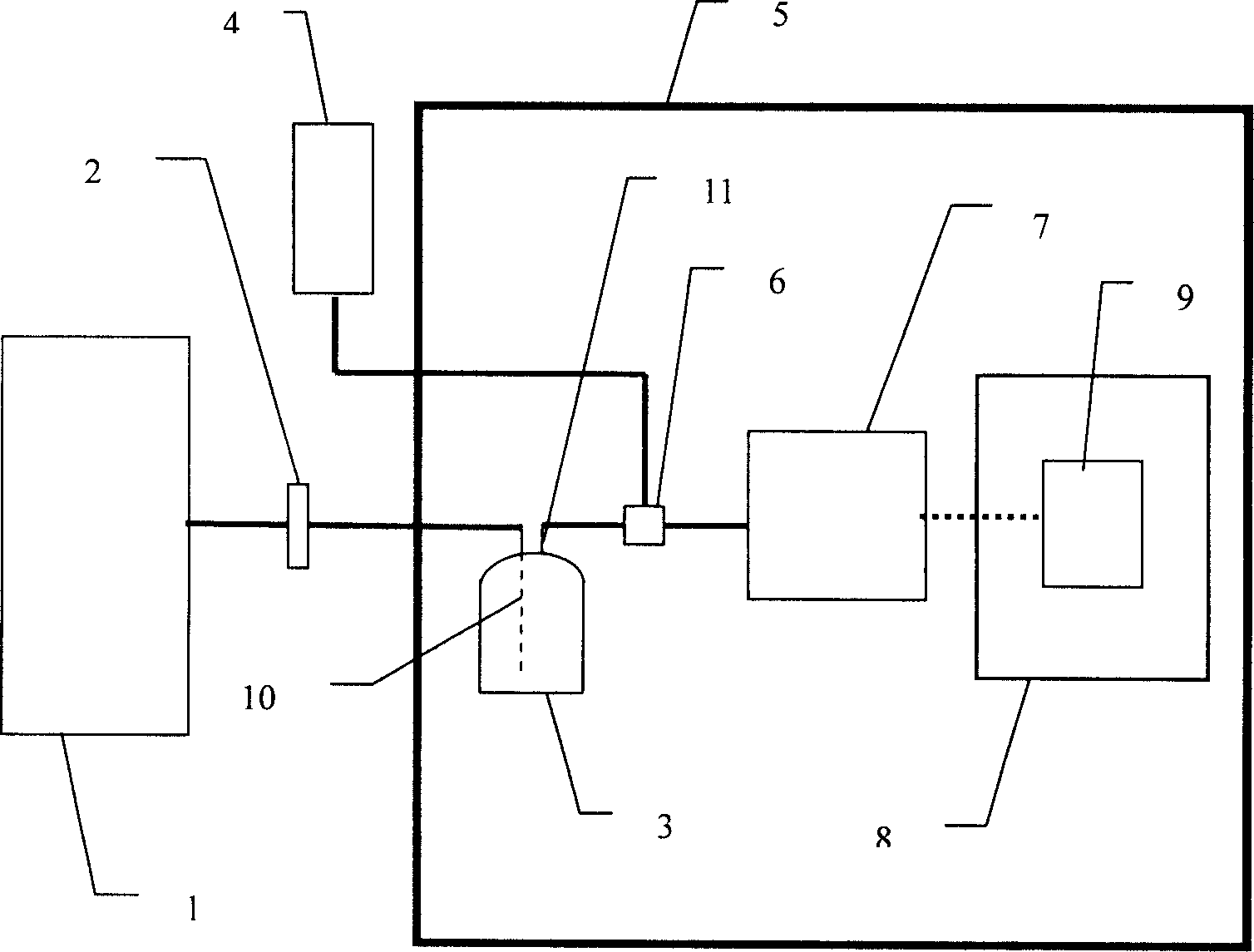

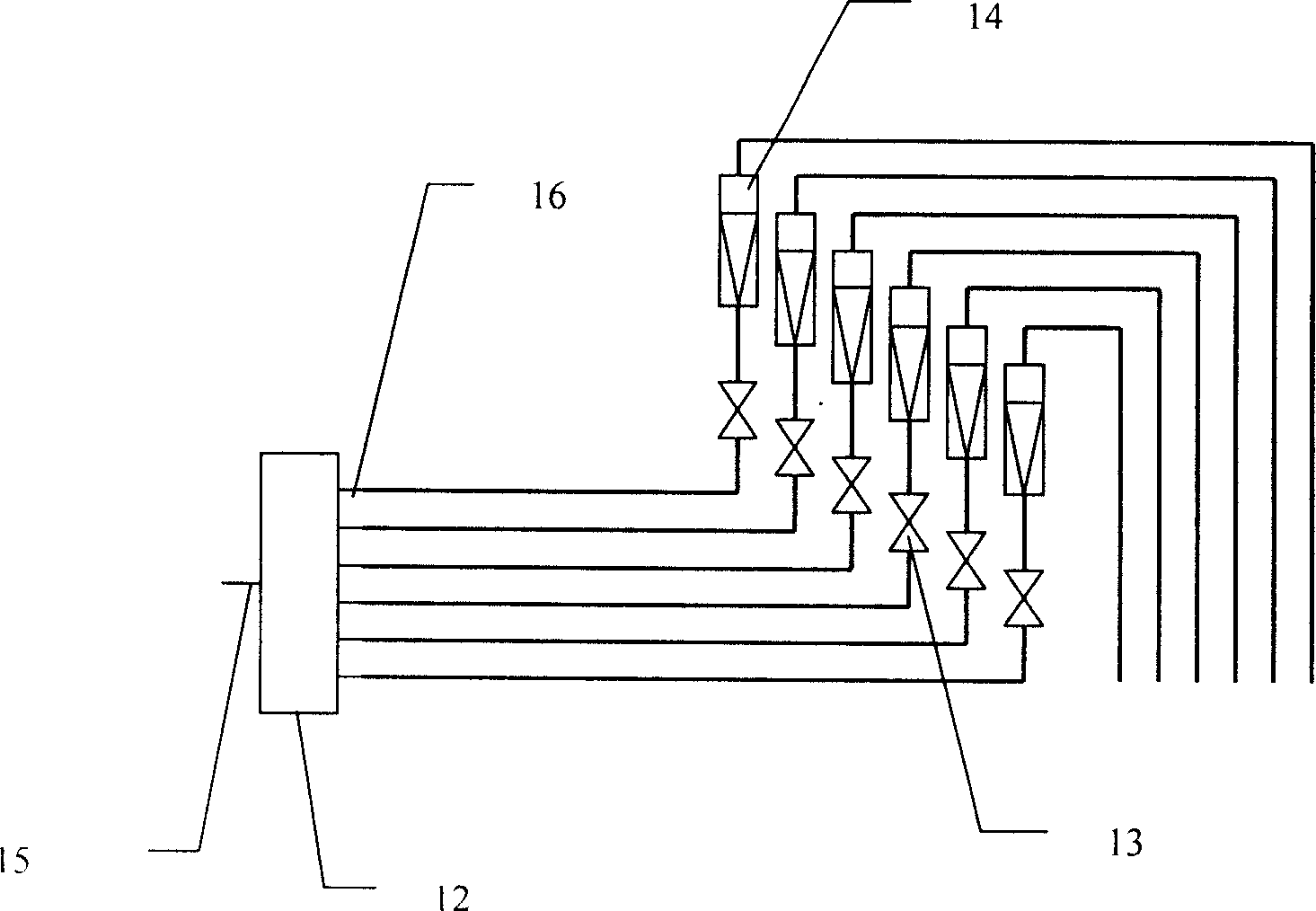

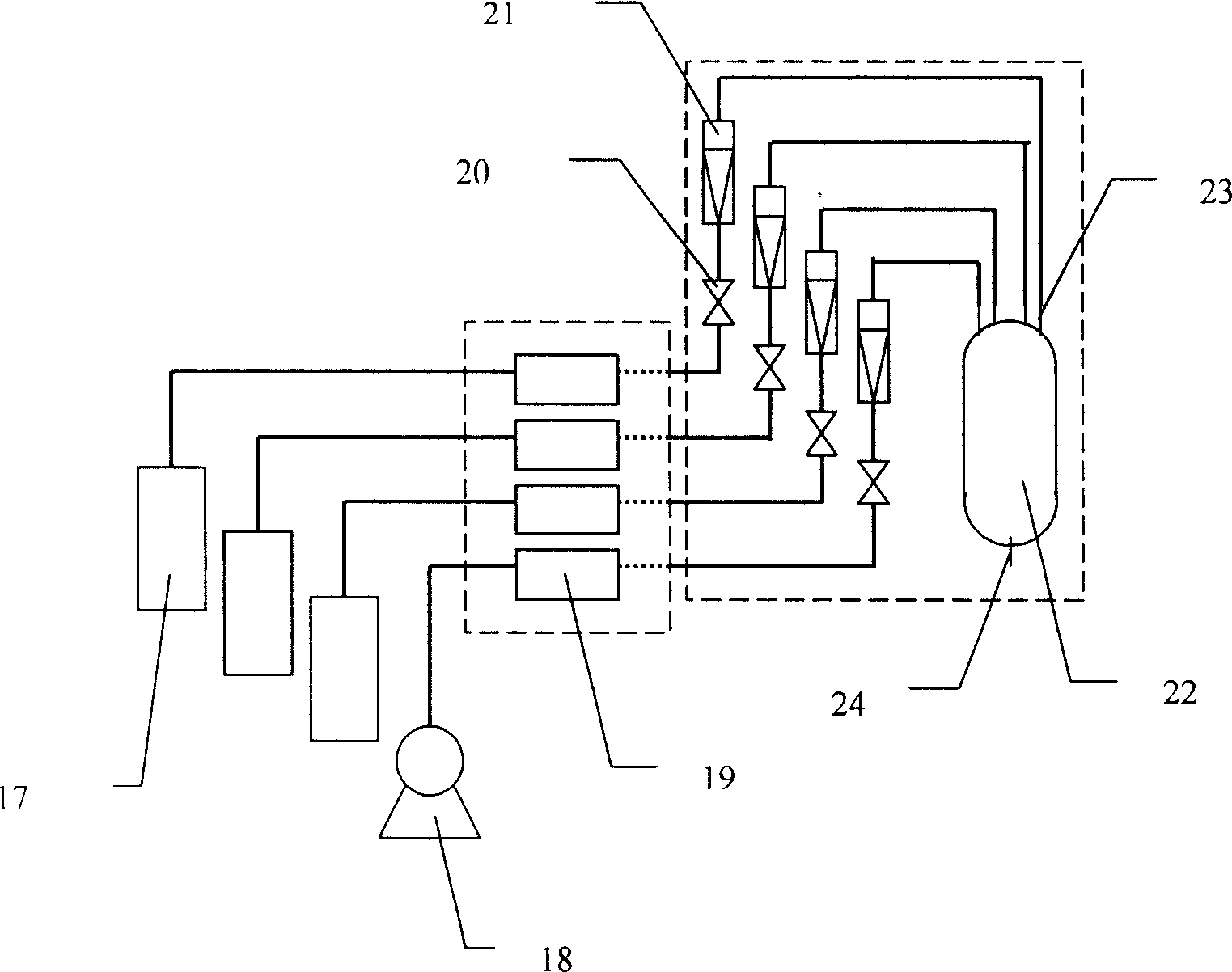

[0023] Such as Figure 1-6 As shown, the present invention includes: an external air supply unit 1, a filter sterilizer 2, a gas humidifier 3, an ethanol steam generator 4, a constant temperature incubator 5, a three-way valve 6, an internal multi-channel gas distribution unit 7, and Mobile lighting system 8, cell culture unit 9. Its connection mode is: external air supply unit 1, filter sterilizer 2 and ethanol steam generator 4 are set outside the constant temperature incubator 5, gas humidification device 3, three-way valve 6, internal multi-channel gas distribution unit 7, can The mobile lighting system 8 and the cell culture unit 9 are set in the constant temperature incubator 5; the main body of the gas humidification device 3 is a cylindrical glass container with a hemispherical top, the top of which is integrated with an air inlet port 10 and an air outlet port 11, and the air inlet port 10 extends into the container near the bottom. The external air supply unit 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com