Impeller or agitator type full-automatic washing machine

A fully automatic washing machine and agitator technology, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of system mass reduction, resonance frequency increase, suspension system manufacturing complexity, etc., to reduce transportation weight and ensure quality , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

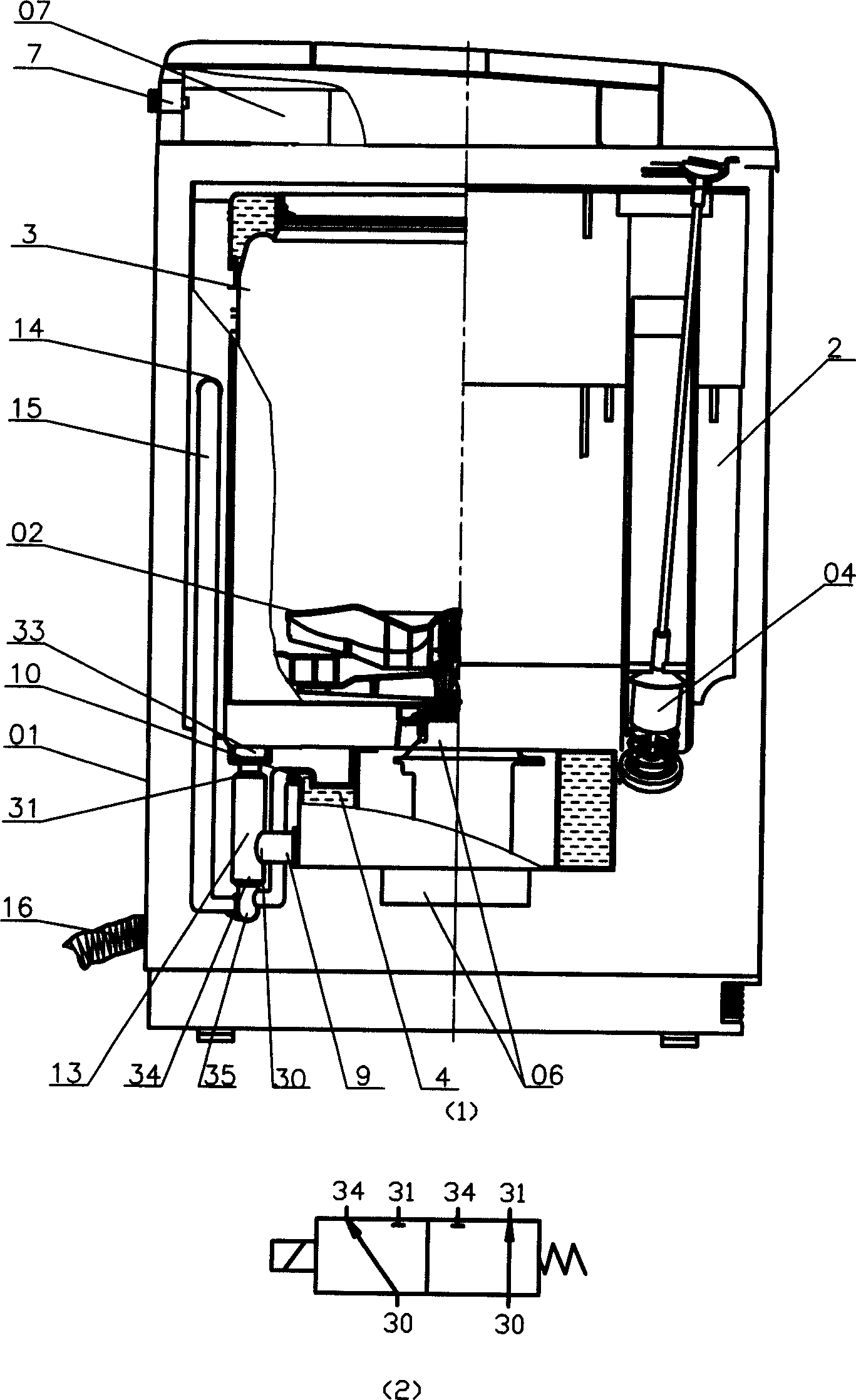

[0025] The washing machine of the first embodiment of the present invention is as figure 1 As shown: the water tub 2 is freely rotatably provided with a washing and dehydrating bucket 3 with a pulsator 02 rotatably provided at the inner bottom; it is hung in the outer casing 01 of the washing machine by the suspension part 04; the automatic controller controls the An integrated direct-drive motor—a deceleration clutch 06 is set at the center of the bottom of the water tank 2, and transmits power to the pulsator 02 and the washing and dehydrating bucket 3; the automatic controller controls the water injected by the water inlet solenoid valve 7 to pass through the water distributor 07 is sprinkled into the washing and dehydrating bucket 3; the bucket 2 is provided with a drain valve 13 at the bottom, and an overflow port 14 is provided at the top; the downstream of the drain valve 13 is connected to the overflow port 14 of the bucket through a vertically upward overflow pipe 15, ...

no. 2 Embodiment

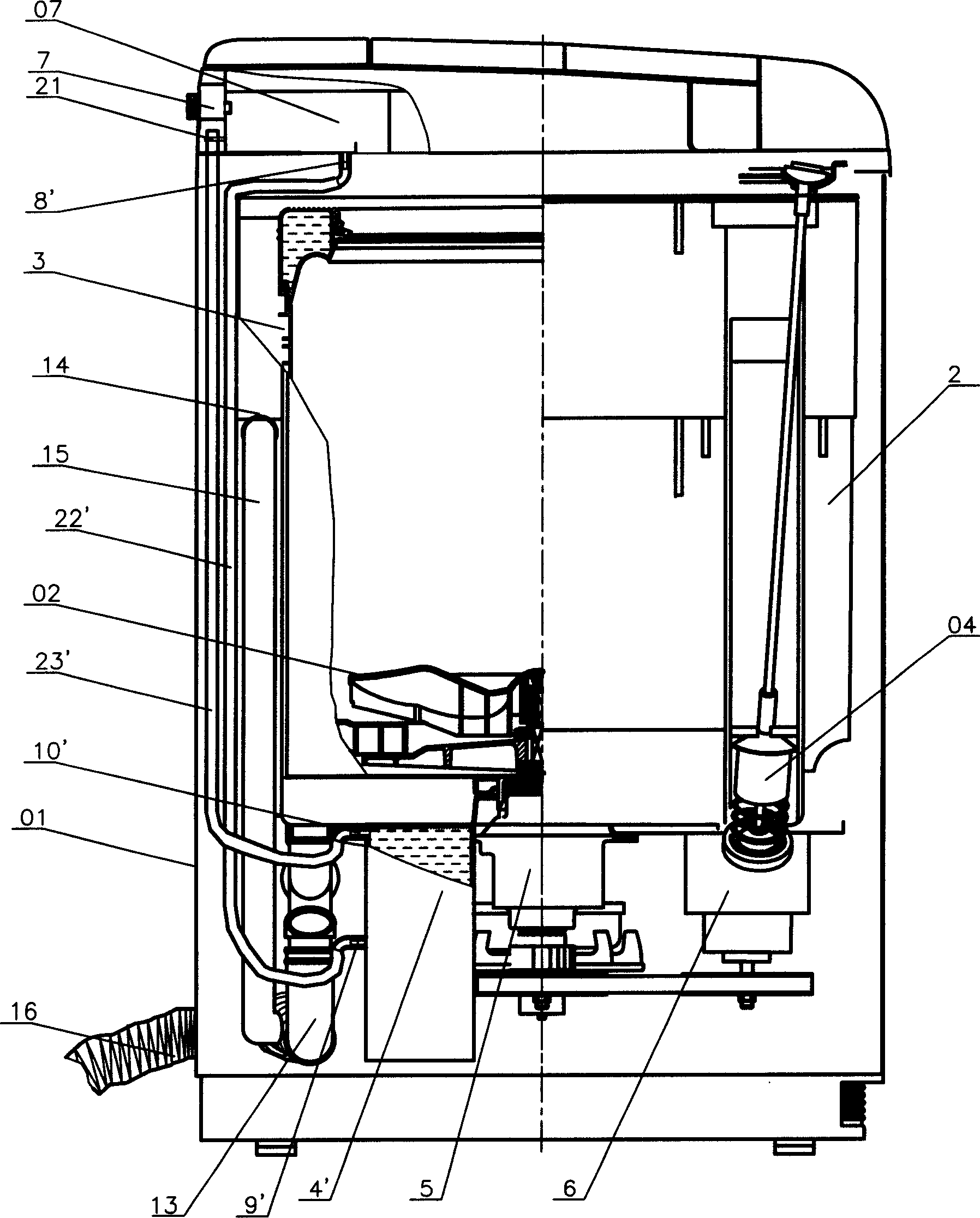

[0035] The washing machine of the second embodiment of the present invention is as image 3 shown. The washing machine has the typical constitution of another pulsator type fully automatic washing machine in the prior art. Its difference with the typical composition of the prior art pulsator type fully automatic washing machine described in the first embodiment is only: the automatic controller controls the power transmission to the pulsator 02 and the washing and dehydration bucket 3 is located at A belt transmission mechanism formed by the deceleration clutch 5 at the center of the bottom of the bucket 2 and the motor 6 on one side.

[0036] The 2nd embodiment washing machine of the present invention is to make following improvement on the basis of such prior art washing machine, see image 3 :

[0037] ——The bottom of the water bucket 2 is combined with a nearly cubic cavity 4' on the other symmetrical side of the motor 6. The cavity 4' can also be processed as an indepe...

no. 3 Embodiment

[0044] A washing machine according to a third embodiment of the present invention is shown in FIG. 4 . The washing machine is a typical structure of the prior art pulsator-type fully automatic washing machine described in Embodiment 1 or Embodiment 2 of the present invention, and the chamber for filling water can be the chamber in the form of Embodiment 1 or Embodiment 2, On the basis of the above, the following improvements are made, as shown in Figure 4:

[0045] - The chamber 4 or 4' is provided with a water injection hole 9" at its lower part and an exhaust overflow hole 10" at its top corner;

[0046] - The water outlet of the solenoid valve 7 is provided with a diversion hole 8";

[0047] ——The overflow pipe 15 is provided with an overflow hole 17 at a height higher than the exhaust overflow hole 10" and lower than the diversion hole 8";

[0048] ——Hose 22" connects water injection hole 9" and diversion hole 8"; hose 23" connects exhaust overflow hole 10" and overflow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com