Plant fiber food packaging material capable of tolerating high-temperature baking and its process

A plant fiber and food packaging technology, applied in packaging, wrapping paper, packaged food, etc., can solve environmental quality problems, decomposition and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

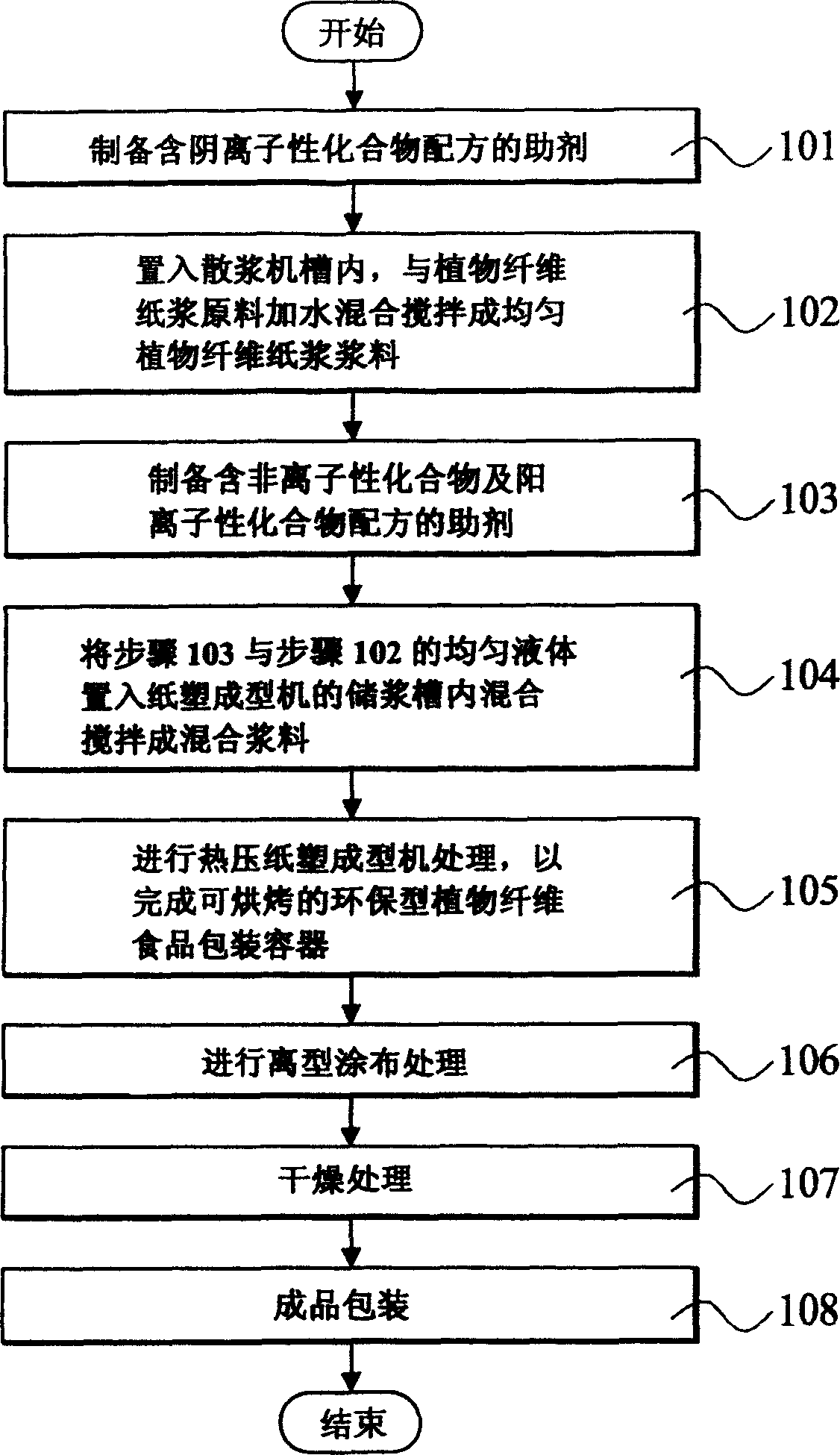

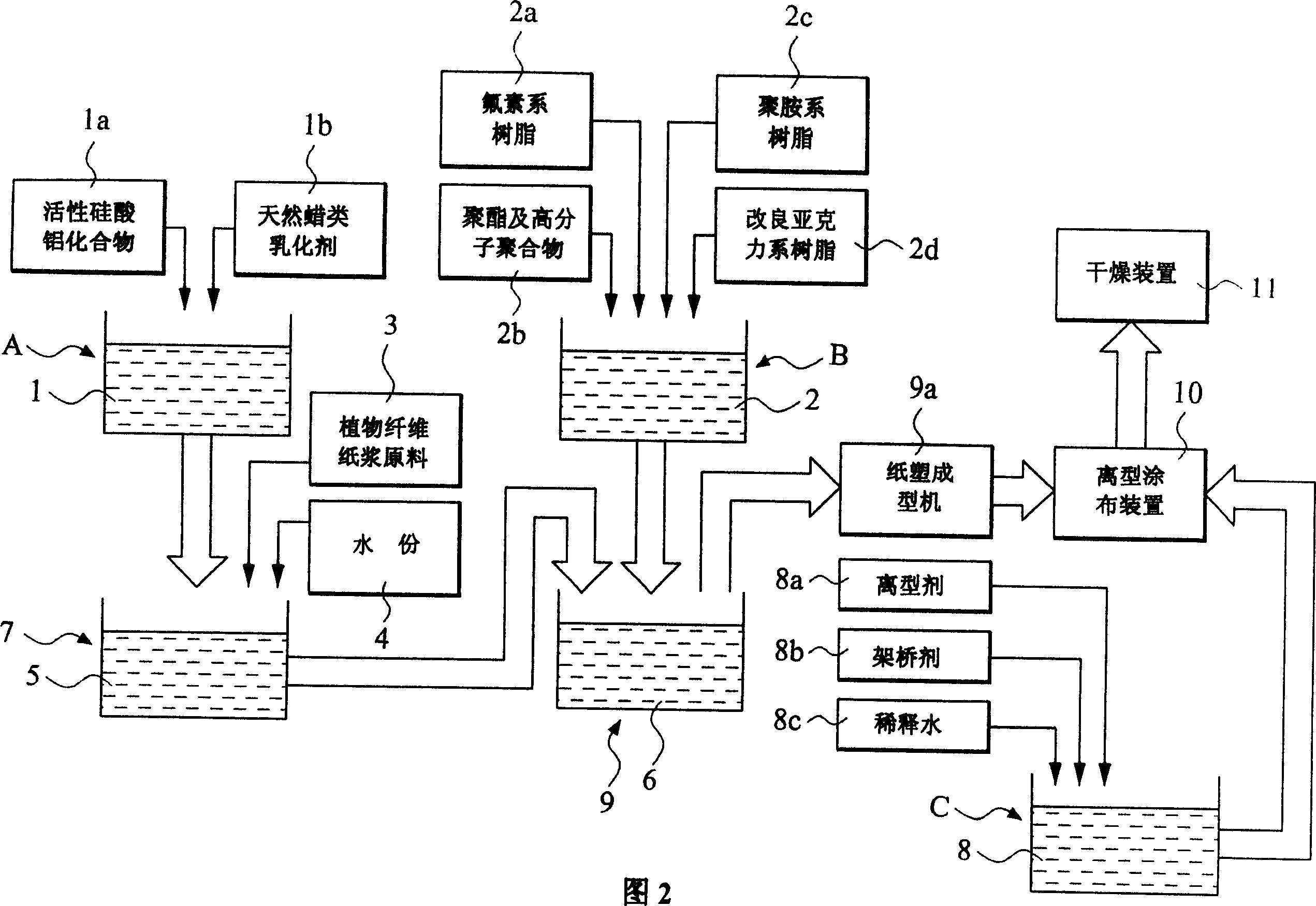

[0044] refer to figure 1 Shown, it is the technology of the vegetable fiber food packaging material that the present invention can withstand high temperature baking, and Fig. 2 is that the present invention realizes figure 1 Schematic diagram of the system for the preparation of the complexes by the process shown.

[0045] see also figure 1And shown in Fig. 2, process technology of the present invention and formula are described in detail as follows. The formula of the high-temperature baking-resistant plant fiber food packaging material of the present invention mainly includes auxiliary agent 1 containing anionic compound formula, auxiliary agent 1 containing nonionic compound formula and cationic compound formula Agent 2, plant fiber pulp raw material 3 and moisture 4 etc. form the mixed slurry 6 according to the manufacturing method of the present invention, and then make the container of the environment-friendly plant fiber food packaging material which can be baked by t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap