Liquid crystal display apparatus and fabrication method of the same

A liquid crystal display and manufacturing method technology, which is applied in microlithography exposure equipment, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve problems such as deterioration of pixel circuit performance and leakage current, and prevent orientation disorder and reduce costs. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

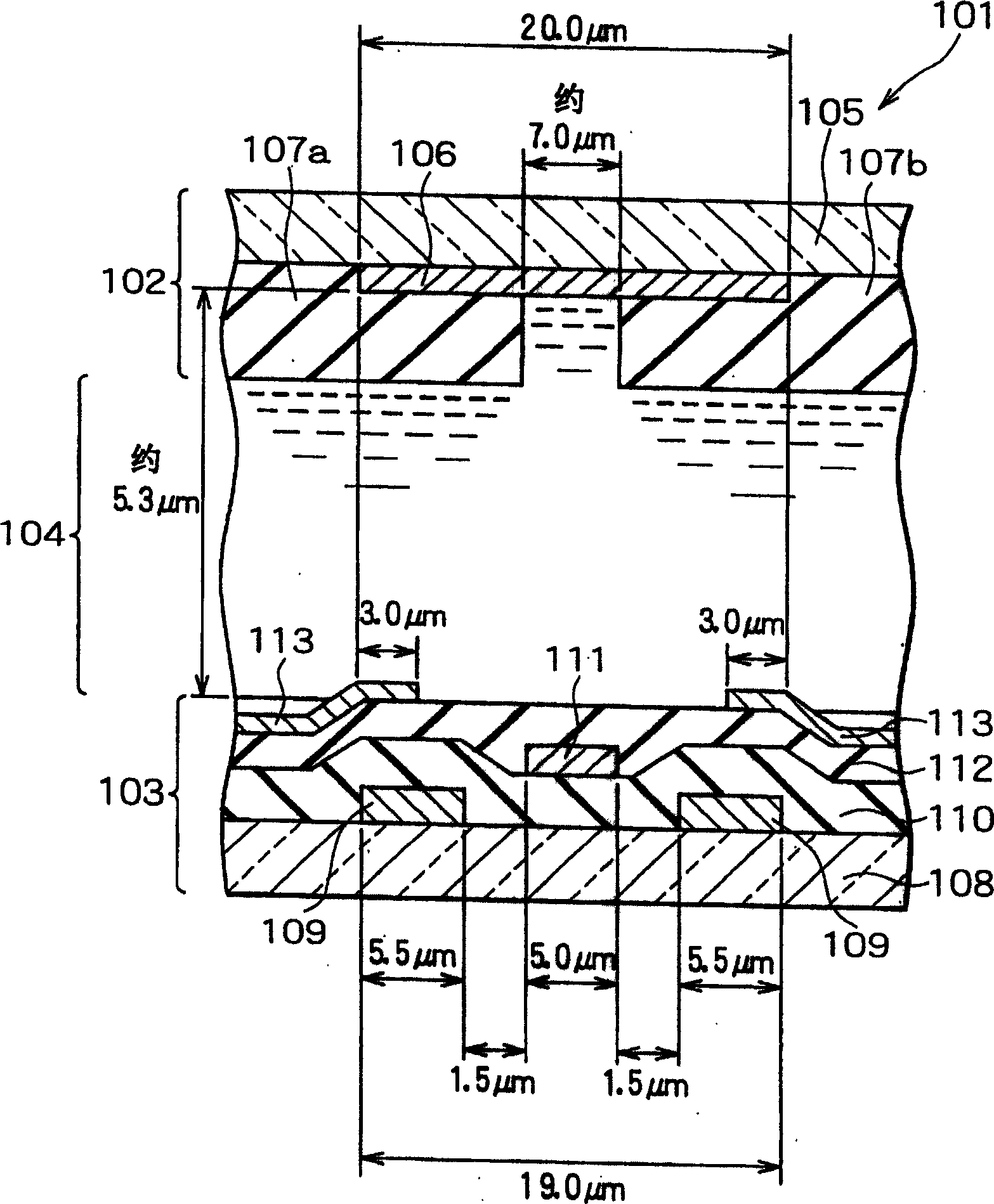

[0035] Embodiments of the present invention will be described below with reference to the drawings. Figure 5 is a sectional view showing a liquid crystal panel of a liquid crystal display device according to an embodiment of the present invention. The size of each part of the liquid crystal panel of this embodiment is Figure 5 shown as an example, but not limited to Figure 5 example shown. In the liquid crystal display device according to the present embodiment, a light source (not shown in the figure), a liquid crystal panel, and a frame body (not shown in the figure) accommodating these components are provided. Furthermore, if Figure 5 As shown, a liquid crystal panel 1 has a color filter substrate 2 and an array substrate 3 placed parallel to each other. A liquid crystal layer 4 is sealed between the color filter substrate 2 and the array substrate 3 .

[0036] In the color filter substrate 2 , there is provided a transparent substrate 5 formed of glass, for example, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com