Low-voltage low-frequency transformer of high-voltage wound asynchronous motor for drining mine hoister

A technology for asynchronous motors and mine hoists, which is applied in the control of motor speed or torque, motor generator control, AC motor control, etc. It can solve problems such as braking capacity limitations, shorten the transformation cycle, and reduce costs , good effect of control characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

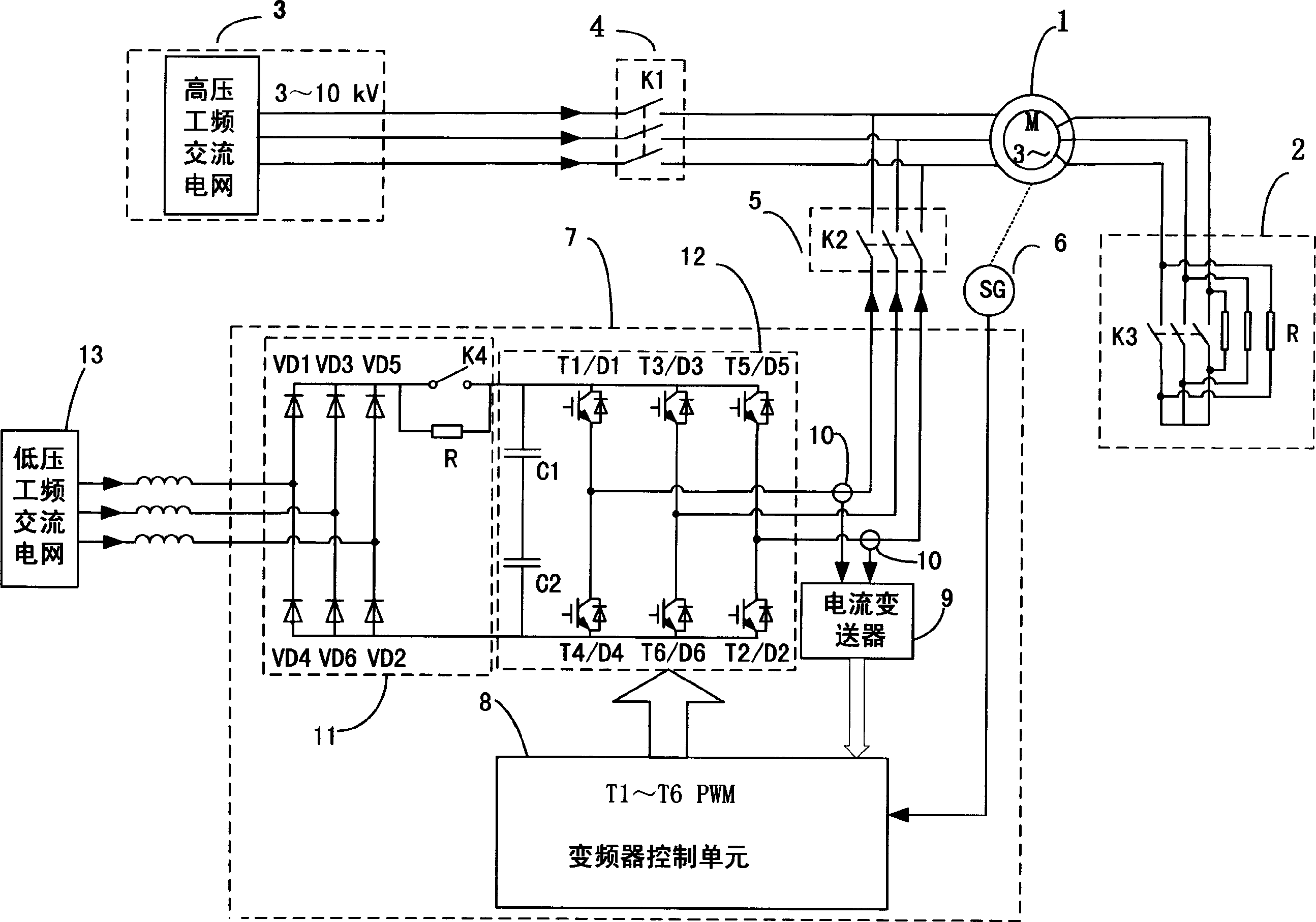

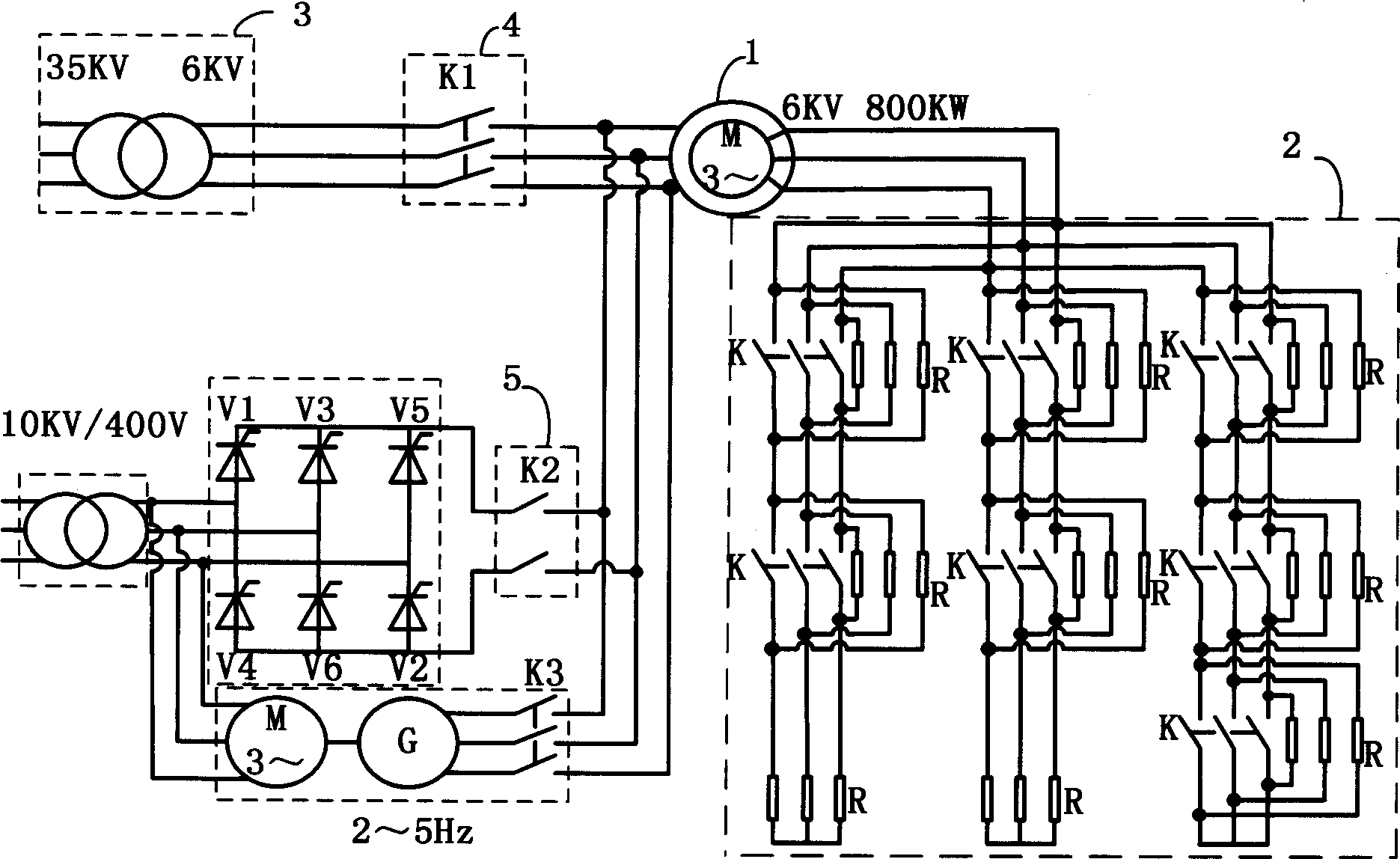

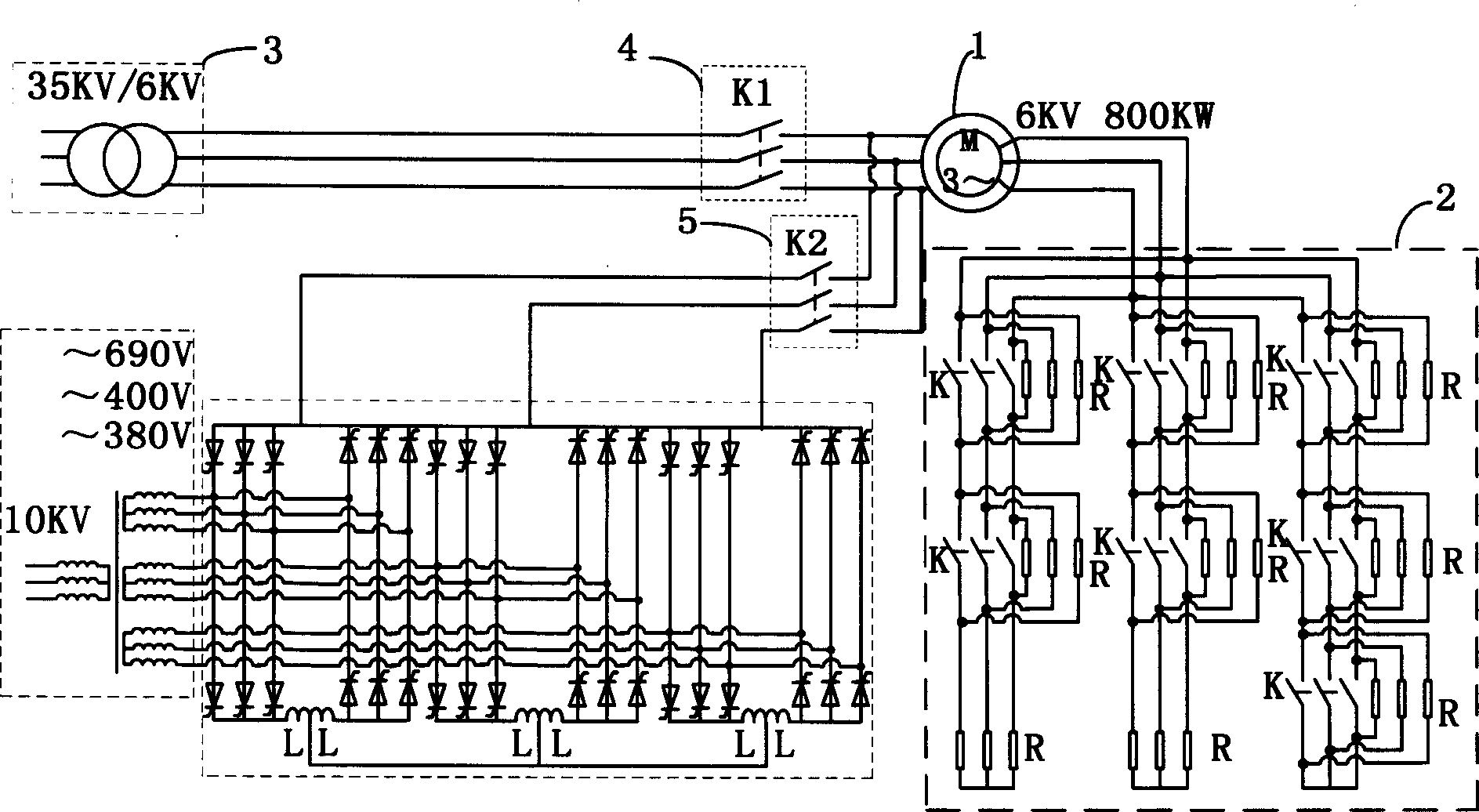

[0031] see figure 1 , figure 1 It is a block diagram of a low-voltage low-frequency frequency converter system for driving a high-voltage winding asynchronous motor of a mine hoist according to the present invention. The mine hoist system of the present invention has DC high-torque braking and low-frequency vector control and high-torque crawling links. The system consists of a High-voltage wound asynchronous motor 1 (model YR800-12 / 1430), load resistor 2, high-voltage power frequency AC power grid 3, high-voltage switching high-voltage switch 4, high-voltage intermittent switching switch 5, and low-voltage low-frequency inverter 7 for control. Take a mine whose depth is 368 meters in a coal mine as an example. K4 type coal feeder and hydraulic tension type steel wire rope tank road are selected, and the skip is a standard bucket of 12t. The original NC thyristor AC-DC-AC frequency conversion speed regulation is changed to a new low-voltage low-frequency DC braking and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com