Laser Raman sample pool for gas analysis

A gas analysis and sample cell technology, which is used in the analysis of materials, material excitation analysis, and material analysis by optical means. It can solve problems such as low collection efficiency, difficult installation, and loose structure, and achieve improved collection efficiency and good sealing , compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

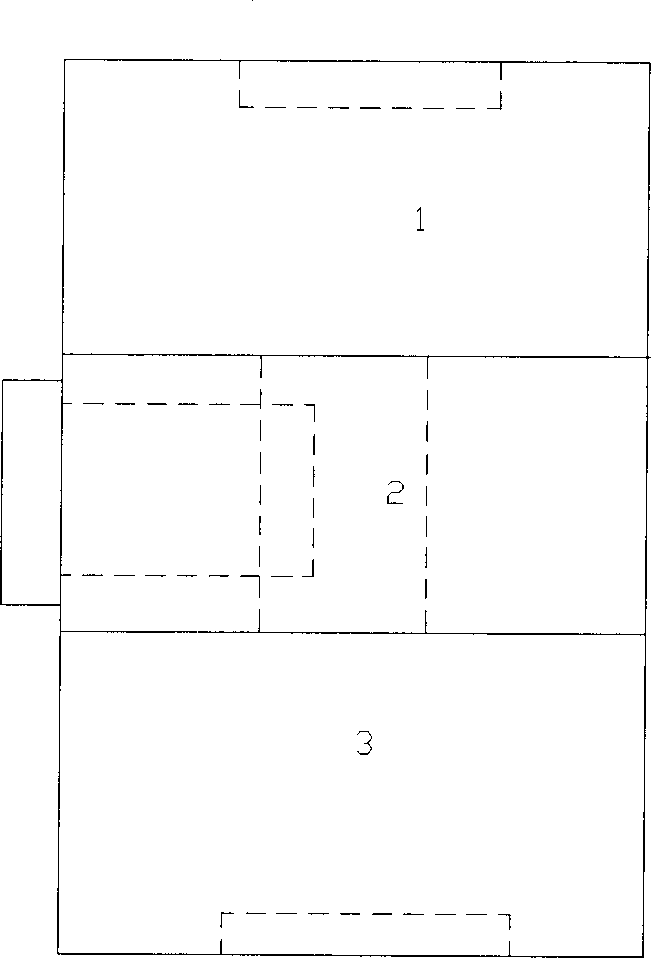

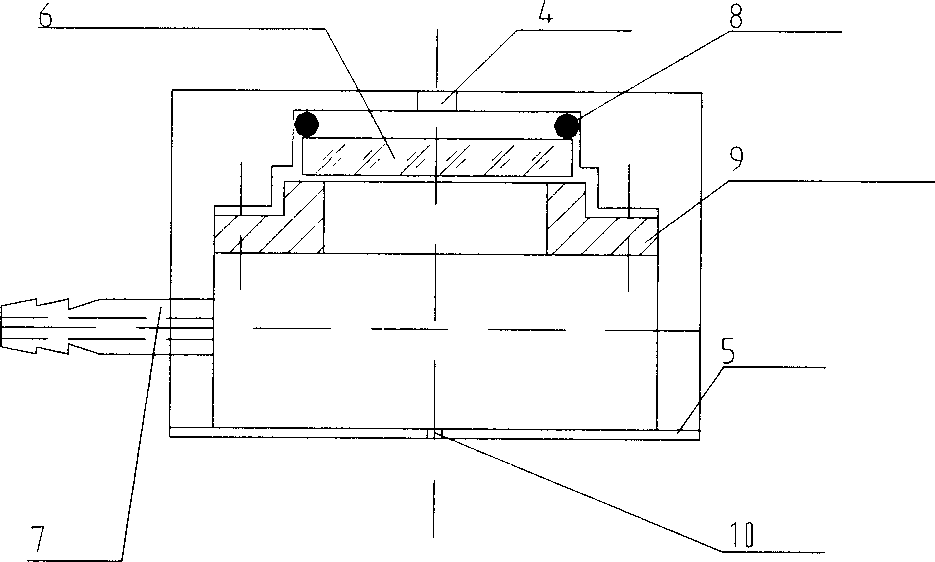

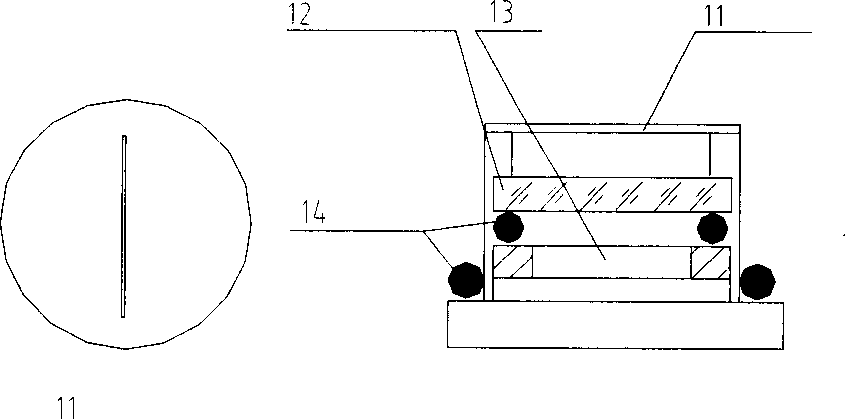

[0028] like Figure 1-4 Shown, the present invention is connected by upper, middle and lower three sections. An aperture aperture 4,5 is respectively arranged on the top and bottom of the upper section 1, a spherical laser mirror 6 is arranged in the middle, the center of curvature is at the center of the middle section 2, and an air nozzle 7 is arranged on the side. The inside of the middle section 2 is a cylindrical hole, which is ground into a cylindrical mirror surface, or electroplated to form a mirror surface after fine milling. A side hole is opened on the front side of the middle section 2, and a hollow cylinder is embedded in the side hole. The cylinder goes deep into one end of the middle section. A thin disc 11 with a slit is pasted, and an interference filter 12 that blocks the laser itself and its Rayleigh scattering is installed behind the thin disc 11, and the filter 12 closes the slit. The lower section 3 is also provided with an aperture aperture 15,16 up and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com