Copper-based non-silver electric contacts with brazing filler metal coating and production thereof

A manufacturing method and layer structure technology, applied in the direction of contact materials, etc., can solve the problems of low welding efficiency, unstable welding quality, affecting the popularization and use of copper-based silver-free electrical contacts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

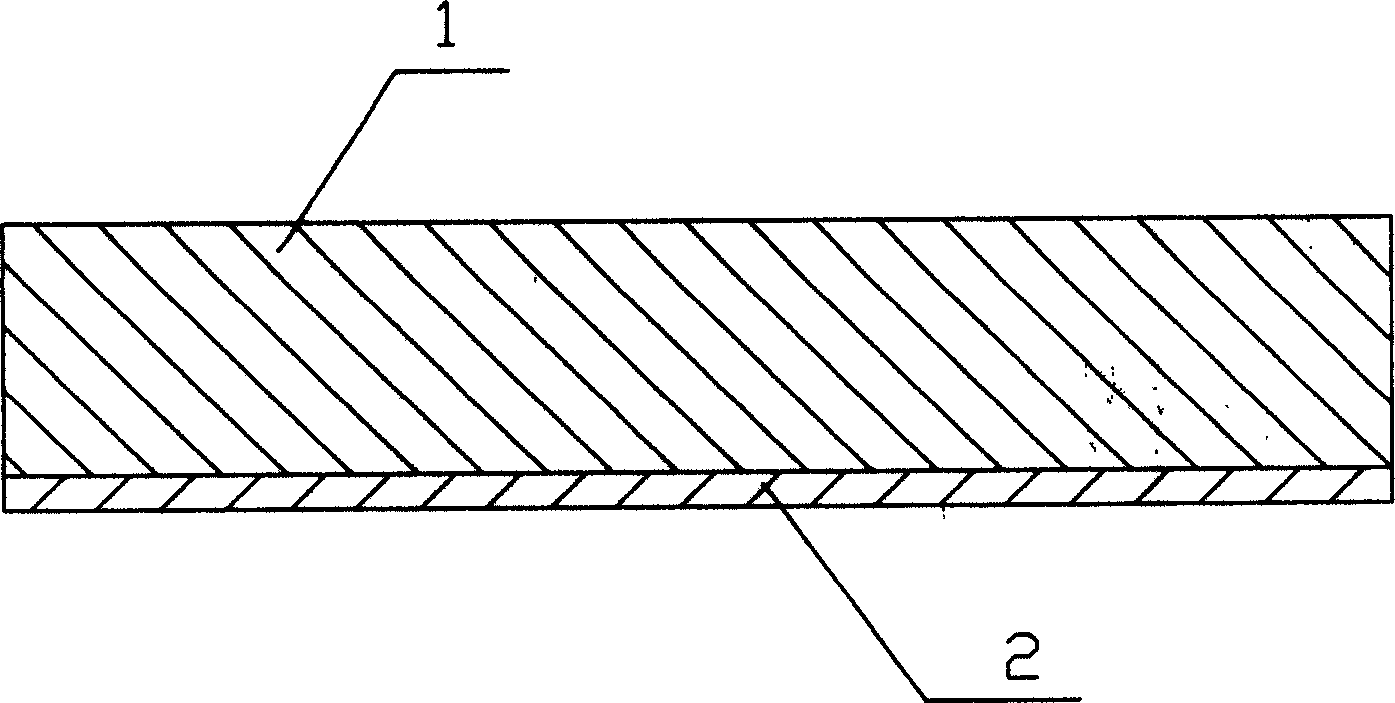

Image

Examples

Embodiment 1

[0012] Embodiment 1 box-type resistance furnace heating method: it is made of copper-based silver-free electrical contact material, brazing filler metal, brazing flux, and the brazing filler metal is evenly melted on the copper-based silver-free electrical contact material by a box-type resistance heating furnace. cost invented products.

Embodiment 2

[0013] Embodiment 2 high, intermediate frequency induction heating method: it is by copper-based silver-free electric contact material, brazing filler metal, brazing flux, by high-frequency, medium-frequency induction heating equipment, brazing filler metal is evenly melted on the copper-based silver-free electric contact material, Make the product of the present invention.

Embodiment 3

[0014] Embodiment 3 sintering method: it is made of copper-based silver-free electrical contact material, brazing material, brazing flux, and solder is evenly melted on the copper-based silver-free electrical contact material by hot-melt equipment to make the product of the present invention .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com