K-type polarizer and preparation thereof

A polarizer, pre-polarization technology, applied in optics, polarizing elements, optical elements, etc., can solve problems such as unsuitable use, polarizers with stripes or spots, etc., and achieve the effect of reducing potential harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0134] Poly(isooctyl acrylate-co-isobornyl acrylate) polymers were prepared by solution polymerization as described below. Isooctyl acrylate (IOA, 90 parts by weight), isobornyl acrylate (IBA, 10 parts by weight), benzyl dimethyl ketal (0.2 parts by weight, available from Sartomer, West Chester PA as Esacure KB-1 ) and ethyl acetate (100 parts by weight, available from EM Science, Gibbstown, NJ) were added to the reaction vessel and injected with N 2 15 minutes and irradiated with UV light (two Sylvania F40 / 350 BL fluorescent tubes, Danvers, MA) for 18 hours with stirring. The samples were diluted with 50 parts by weight of ethyl acetate and used to prepare the following examples. A series of examples were carried out by mixing 10 parts by weight of the above polymer, 0-0.4 parts by weight of cyanuric chloride, and 0-1 part by weight of 1-decanol.

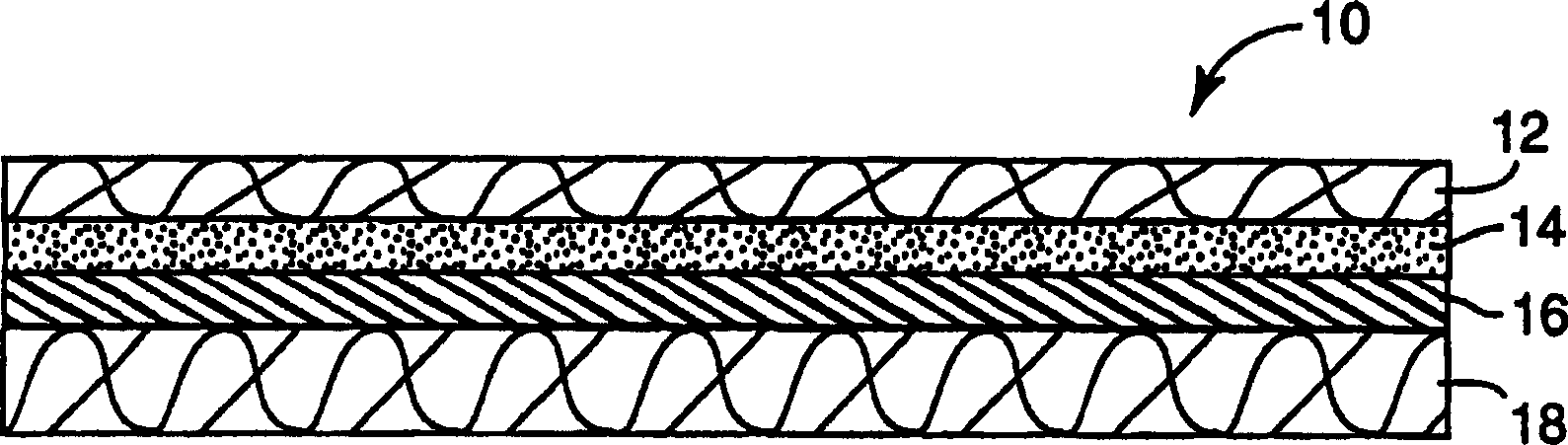

[0135] Each solution was coated onto pre-oriented polyvinyl alcohol (PVA) film at a wet thickness of 0.508 mm using an eight-p...

Embodiment 2

[0142] Poly(IOA-co-IBA) polymer was prepared as described in Example 1. A series of examples were performed by mixing 10 parts by weight of this polymer overnight with 0-0.4 parts by weight of cyanuric chloride and 0-1.05 parts by weight of 1-decanol. Sandwich structures were obtained as described in Example 1 using these solutions. Conversion was then achieved by placing them in an oven at 165°C for 15 minutes. All of the examples except Example 2A exhibited the maroon red color characteristic of partially dehydrated PVA after heating. The results are listed in Table 2.

[0143] Example

Cyanuric chloride

parts by weight

1-Decanol

parts by weight

color

2A *

2B

2C

2D

2E

2F

2G

2H

0

0.02

0.041

0.12

0.2

0.2

0.28

0.401

0

0.057

0.109

0.312

0.521

0

0.73

1.049

none

uneven bright reddish brown...

Embodiment 3

[0147] Copolymers of isooctyl acrylate (IOA) and acrylamide were prepared by solution polymerization. Prepare the 2-propanol (EM Science, Gibbstown, NJ) and 150 parts by weight of ethyl acetate (EM Science, Gibbstown, NJ). Nitrogen was bubbled through the mixture for 15 minutes, then heated at 65° C. for 24 hours with stirring. A sample was obtained by mixing 10 parts by weight of the resulting polymer solution overnight with 0.2 parts by weight of cyanuric chloride and 0.52 parts by weight of 1-decanol. The mixture turned white overnight. The sandwich structure was obtained and transformed as described in Example 1. Upon heating, this example converted to the maroon red character of partially dehydrated PVA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com