Debris flow sediment transport control method suitable for broad valley type debris flow gully

A control method and debris flow technology, applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve problems such as lack of development and utilization of sediment resources, difficulty in achieving the expected goal of governance, and reduced reservoir capacity, so as to improve governance effectiveness and high efficiency The effect of development, utilization and improvement of ecological landscape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

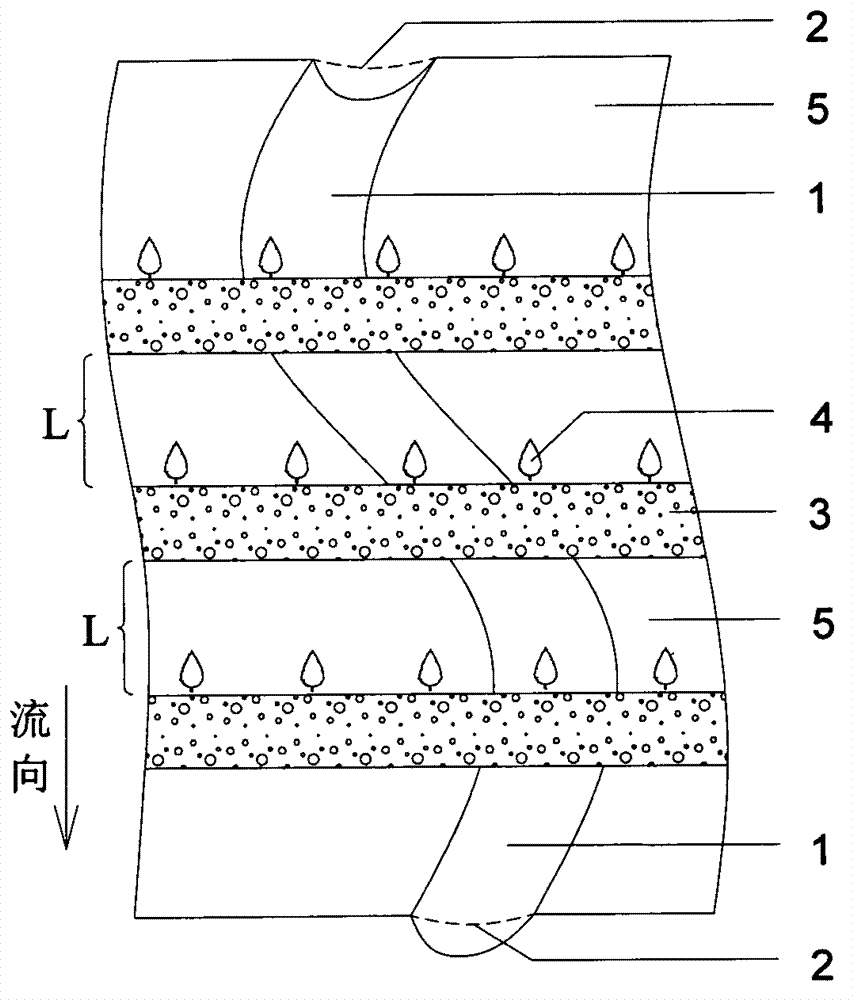

[0027] Such as figure 1 , Figure 4 , Figure 5 shown. For a wide valley type debris flow valley with a longitudinal slope of 3-5 degrees and a transverse width of 50-200m, the debris flow control method of the present invention is used in the wide valley type valley.

[0028] In the debris flow flow area and accumulation area in the gully, the existing loose solid matter on the ditch bed is used to backfill the sand transport ditch 1 on the ditch bed. The trench bed surface 5 jointly forms a flat and wide trench bed surface. In the debris flow circulation area and accumulation area in the valley, use the existing loose solid materials on the ditch bed to build 15 sand-retaining earth walls 3 horizontally along the valley contour line and distributed at a certain interval; the specifications of each earth wall 3: The top width b1 of the earth wall 3 is 0.8m, the bottom width b2 of the earth wall 3 is 1.0m, the height h of the earth wall 3 is 0.6m, and the length of the ear...

Embodiment 2

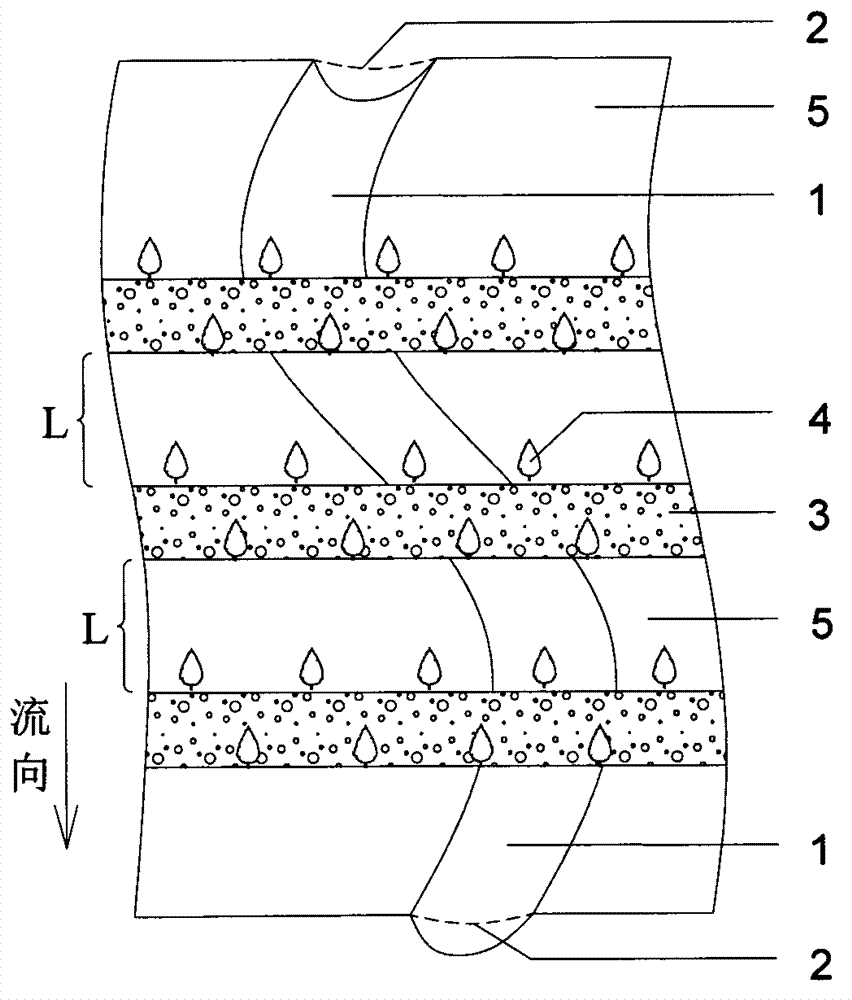

[0030] Such as figure 2 , Figure 4 , Figure 6 shown. For a wide valley type debris flow valley with a gully bed longitudinal slope of 6-8 degrees and a valley transverse width of 180-320m, the debris flow and sand transport control method of the present invention is used in the wide valley type valley.

[0031] In the debris flow flow area and accumulation area in the gully, the existing loose solid matter on the ditch bed is used to backfill the sand transport ditch 1 on the ditch bed. The trench bed surface 5 jointly forms a flat and wide trench bed surface. In the debris flow circulation area and accumulation area in the valley, use the existing loose solid materials on the ditch bed to build 12 sand-retaining earth walls 3 horizontally along the valley contour line and distributed at a certain interval; the specifications of each earth wall 3: The top width b1 of the earth wall 3 is 1.2m, the bottom width b2 of the earth wall 3 is 2.2m, the height h of the earth wal...

Embodiment 3

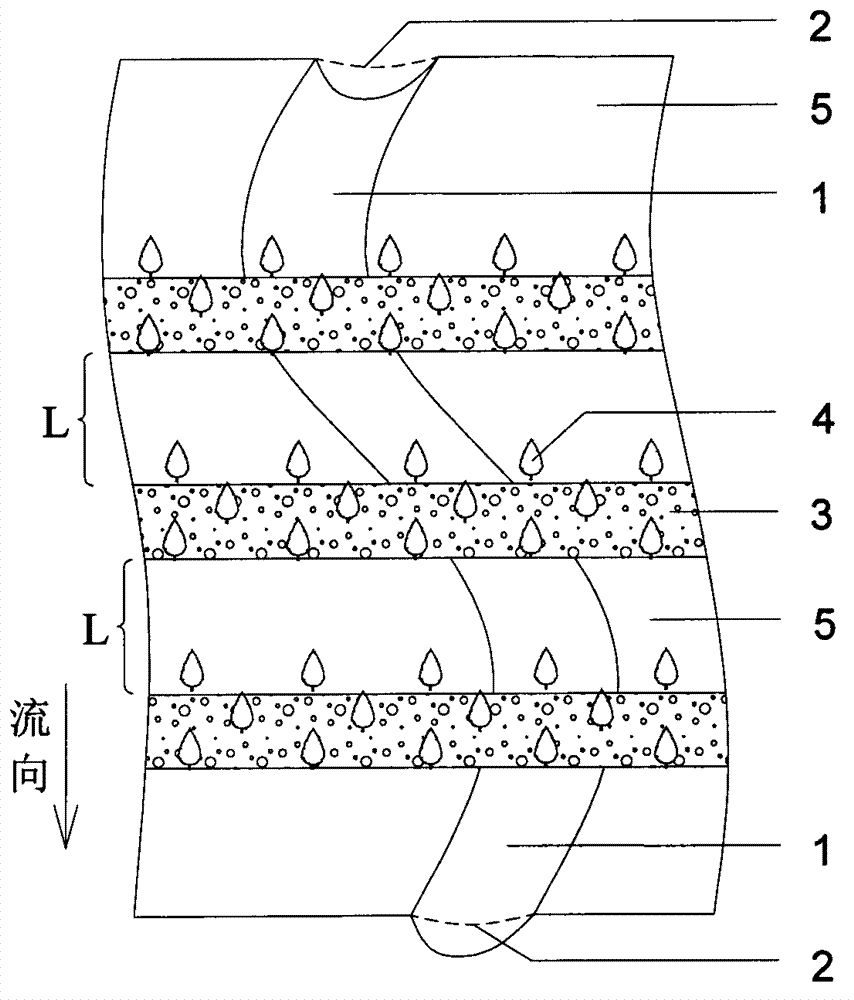

[0033] Such as image 3 , Figure 4 , Figure 7 shown. For a wide valley type debris flow valley with a gully bed longitudinal slope of 11-13 degrees and a valley transverse width of 220-360m, the debris flow and sand transport control method of the present invention is used in the wide valley type valley.

[0034] In the debris flow flow area and accumulation area in the valley, the existing loose solid matter on the ditch bed is used to backfill the sand transport ditch 1 on the ditch bed. The trench bed surface 5 jointly forms a flat and wide trench bed surface. In the debris flow circulation area and accumulation area in the valley, use the existing loose solid materials on the ditch bed to build 8 sand-retaining earth walls 3 distributed in a certain interval along the contour line of the valley; the specification of each earth wall 3: soil The top width b1 of the wall 3 is 1.5m, the bottom width b2 of the earth wall 3 is 2.6m, the height h of the earth wall 3 is 1.8m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com