Adsorption and degradation material as well as preparation method and application thereof

An adsorption degradation and reaction technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, and other chemical processes, etc., can solve the problems of limited adsorption capacity and excessive silver concentration, so as to enhance adsorption effect, reduce potential harm, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

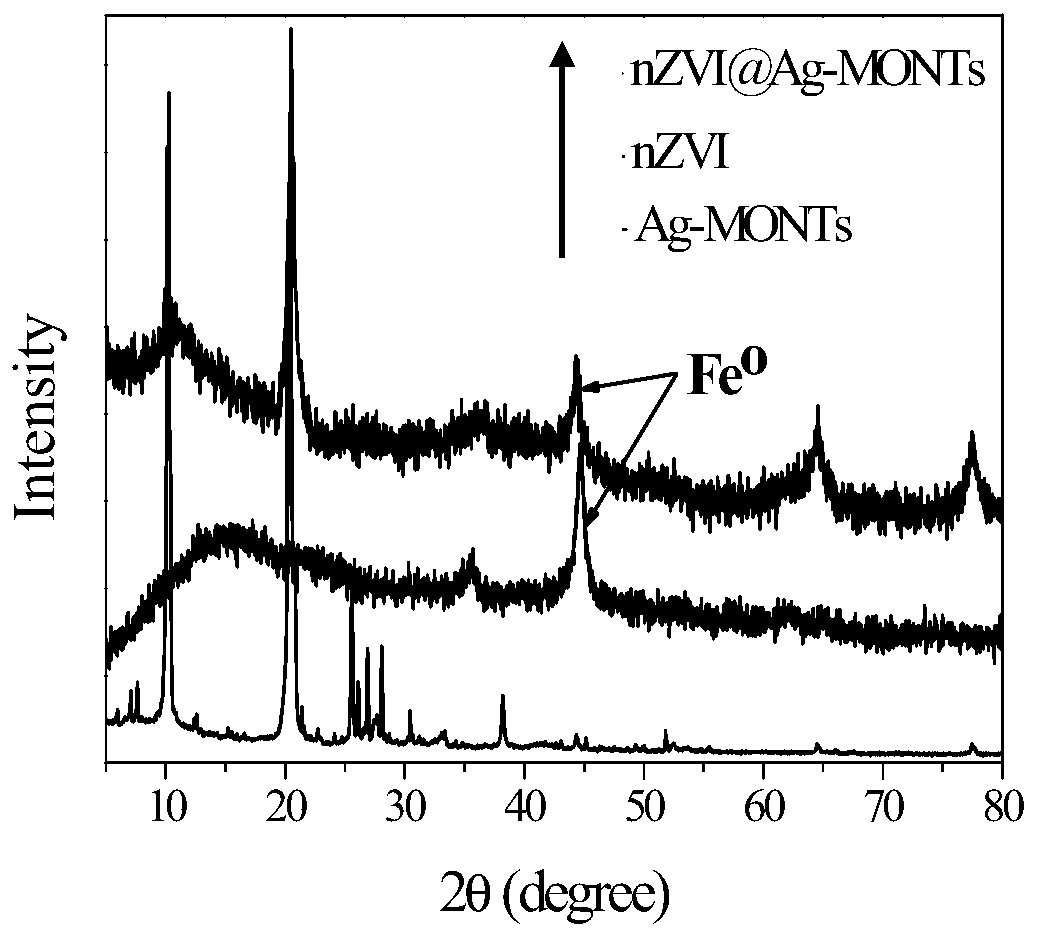

[0038] The preparation method of embodiment 1 adsorption degradation material

[0039](1) Dissolve 0.034g of silver nitrate and 0.021g of 1,2,3-benzenetricarboxylic acid in 7mL of water, then add 0.031g of 4,4-bipyridine to it, ultrasonically dissolve, then add 295μL of 1mol / L KOH solution to adjust the pH value to 6.0, and finally the mixture was transferred to a 25mL polytetrafluoroethylene autoclave. The initial temperature was 30°C, raised to 160°C in 4 hours, maintained at 160°C for 36 hours, and then cooled to 30°C in 6 hours. Alternately washing with ethanol and water for 2-3 times, and drying to obtain metal-organic nanotube material Ag-MONTs.

[0040] (2) Add 5ml of anaerobic deionized water to a 50ml Erlenmeyer flask, then add FeSO 4 ·7H 2 O and the Ag-MONTs powder prepared in step (1) (the mass ratio of nZVI to Ag-MONTs is 1:1), stirred at room temperature for about 3h to disperse. Afterwards, under nitrogen protection, 5ml (16g / L) of newly configured NaBH 4 Th...

Embodiment 2

[0041] The preparation method of embodiment 2 adsorption degradation material

[0042] (1) Dissolve 0.034g of silver nitrate and 0.021g of 1,2,3-benzenetricarboxylic acid in 7mL of water, then add 0.031g of 4,4-bipyridine to it, ultrasonically dissolve, then add 295μL of 1mol / L KOH solution to adjust the pH value to 6.0, and finally the mixture was transferred to a 25mL polytetrafluoroethylene autoclave. The initial temperature was 30°C, raised to 160°C in 3 hours, maintained at 160°C for 48 hours, and then cooled to 30°C in 12 hours. Alternately washing with ethanol and water for 2-3 times, and drying to obtain metal-organic nanotube material Ag-MONTs.

[0043] (2) Add 10ml of oxygen-free deionized water to a 50ml Erlenmeyer flask, then add FeSO 4 ·7H 2 O and the Ag-MONTs powder prepared in step (1) (the mass ratio of nZVI to Ag-MONTs is 1:2), stirred at room temperature for about 4h to disperse. Afterwards, under nitrogen protection, 10ml (8g / L) of newly configured NaBH ...

Embodiment 3

[0044] The preparation method of embodiment 3 adsorption degradation material

[0045] (1) Dissolve 0.034g of silver nitrate and 0.021g of 1,2,3-benzenetricarboxylic acid in 7mL of water, then add 0.031g of 4,4-bipyridine to it, ultrasonically dissolve, then add 295μL of 1mol / L KOH solution to adjust the pH value to 6.0, and finally the mixture was transferred to a 25mL polytetrafluoroethylene autoclave. The initial temperature was 30°C, raised to 160°C in 2 hours, maintained at 160°C for 60 hours, and then cooled to 30°C in 18 hours. Alternately washing with ethanol and water for 2-3 times, and drying to obtain metal-organic nanotube material Ag-MONTs.

[0046] (2) Add 20ml of oxygen-free deionized water to a 50ml Erlenmeyer flask, then add FeSO 4 ·7H 2 O and the Ag-MONTs powder prepared in step (1) (the mass ratio of nZVI to Ag-MONTs is 1:5), stirred at room temperature for about 6h to disperse. Afterwards, under nitrogen protection, 20ml (4g / L) of newly configured NaBH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com