Ink for ink jet recording

A technology of inkjet recording ink and ink, which is applied in the direction of ink, printing, household utensils, etc., and can solve problems such as insufficient solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

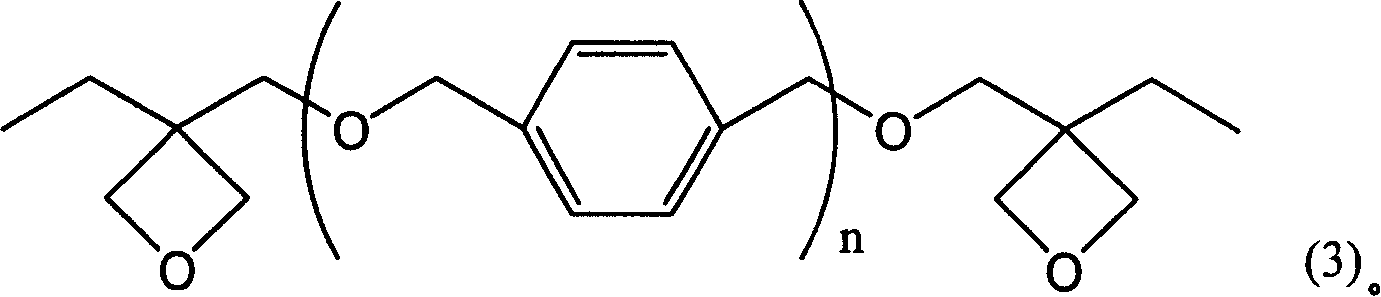

[0033] Next, various embodiments of the present invention will be explained in detail.

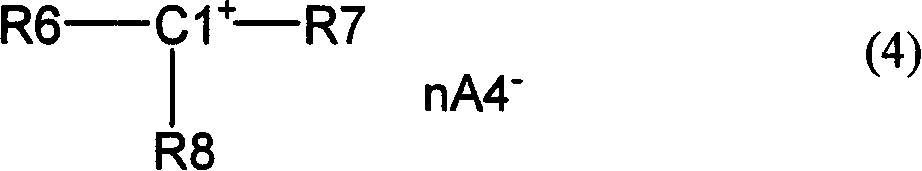

[0034] In the inkjet recording ink as described in each embodiment of the present invention, various photo-acid generators capable of generating acid upon exposure to light include onium salts, diazonium salts, quinonediazide compounds, organic halides, aromatic sulfonates, Acid compounds, bisulfone compounds, sulfonyl compounds, sulfonic acid compounds, sulfonium compounds, sulfonamide compounds, iodonium compounds, sulfonyldiazomethane compounds, and mixtures of these compounds.

[0035]Specific examples of the above compounds include triphenylsulfonium triflate, diphenyliodonium triflate, 2,3,4,4-tetrahydroxybenzophenone-4-naphthoquinonediazide Sulfonate, 4-N-phenylamino-2-methoxyphenyldiazosulfate, 4-N-phenylamino-2-methoxyphenyldiazo-p-ethylphenylsulfate, 4-N- Phenylamino-2-methoxyphenyldiazo-2-naphthylsulfate, 4-N-phenylamino-2-methoxyphenyldiazophenylsulfate, 2,5-diethoxy- 4-N-4'-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com