Synthetic resin forming product and producing method thereof

A technology of synthetic resin and manufacturing method, which is applied to other household appliances, household components, lighting and heating equipment, etc., can solve the problem of expensive molds, and achieve the effect of reducing the number of processes, reducing costs, and overall beauty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

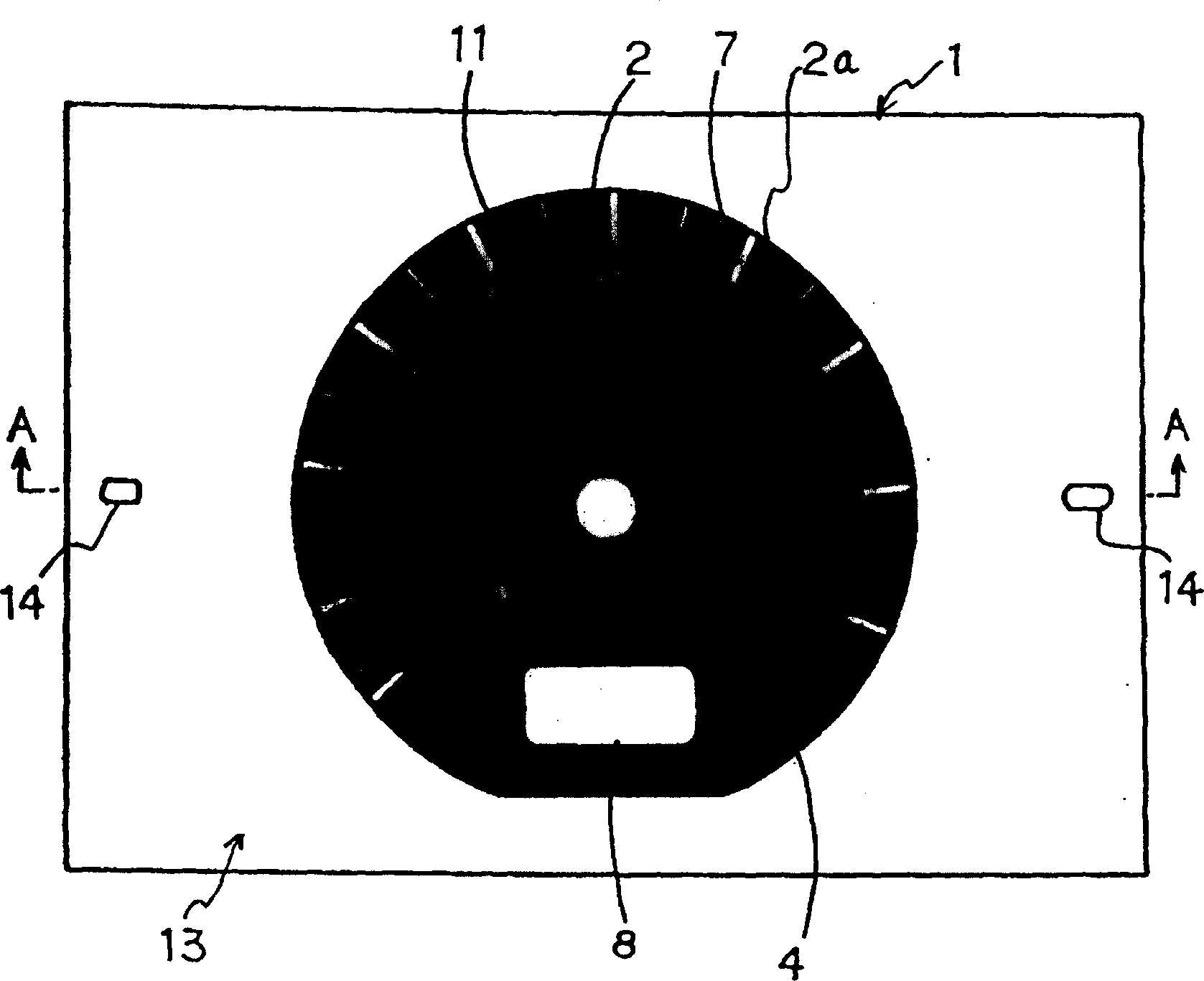

[0045] Such as figure 1 , 2 As shown, a small-diameter hole for inserting a rotating shaft 6 for a meter pointer is formed in the center of the synthetic resin plate 2 provided on the front of the panel for an automobile speedometer shown as the synthetic resin molded product 1 of this embodiment. 4, and form a scale and a numerical value 7 around it, and then form a window 8 for the odometer at the bottom.

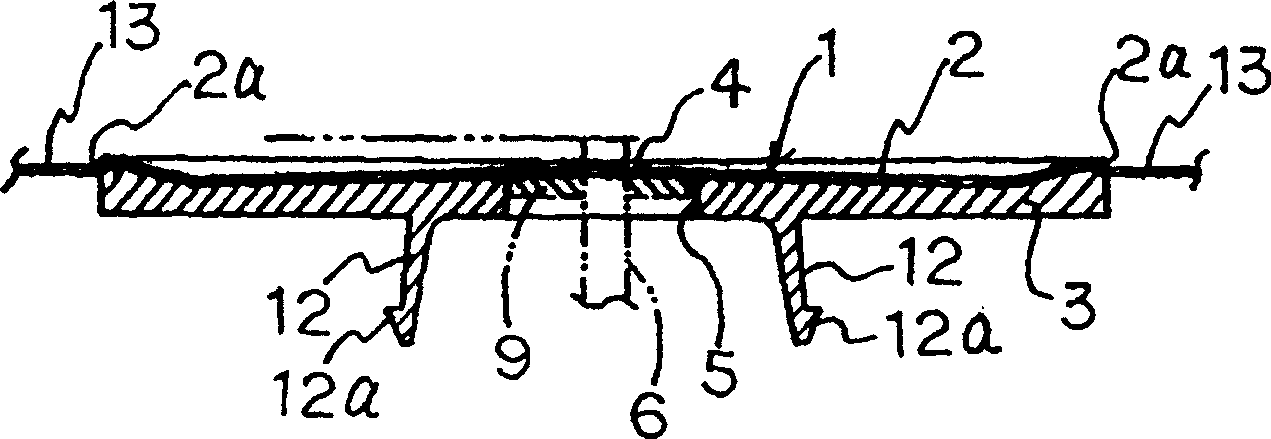

[0046] In addition, the above-mentioned small-diameter hole 4 is formed in the center of the synthetic resin plate 2 , and a large-diameter hole 5 larger than the small-diameter hole 4 is formed in the center of the synthetic resin molded part 3 corresponding to the formation portion of the small-diameter hole 4 .

[0047] Such as figure 2 As shown, the inner diameters of the small-diameter hole 4 of the synthetic resin plate 2 and the large-diameter hole 5 of the synthetic resin molding part 3 are different because the rotating shaft 6 of the instrument pointer is ins...

Embodiment 2

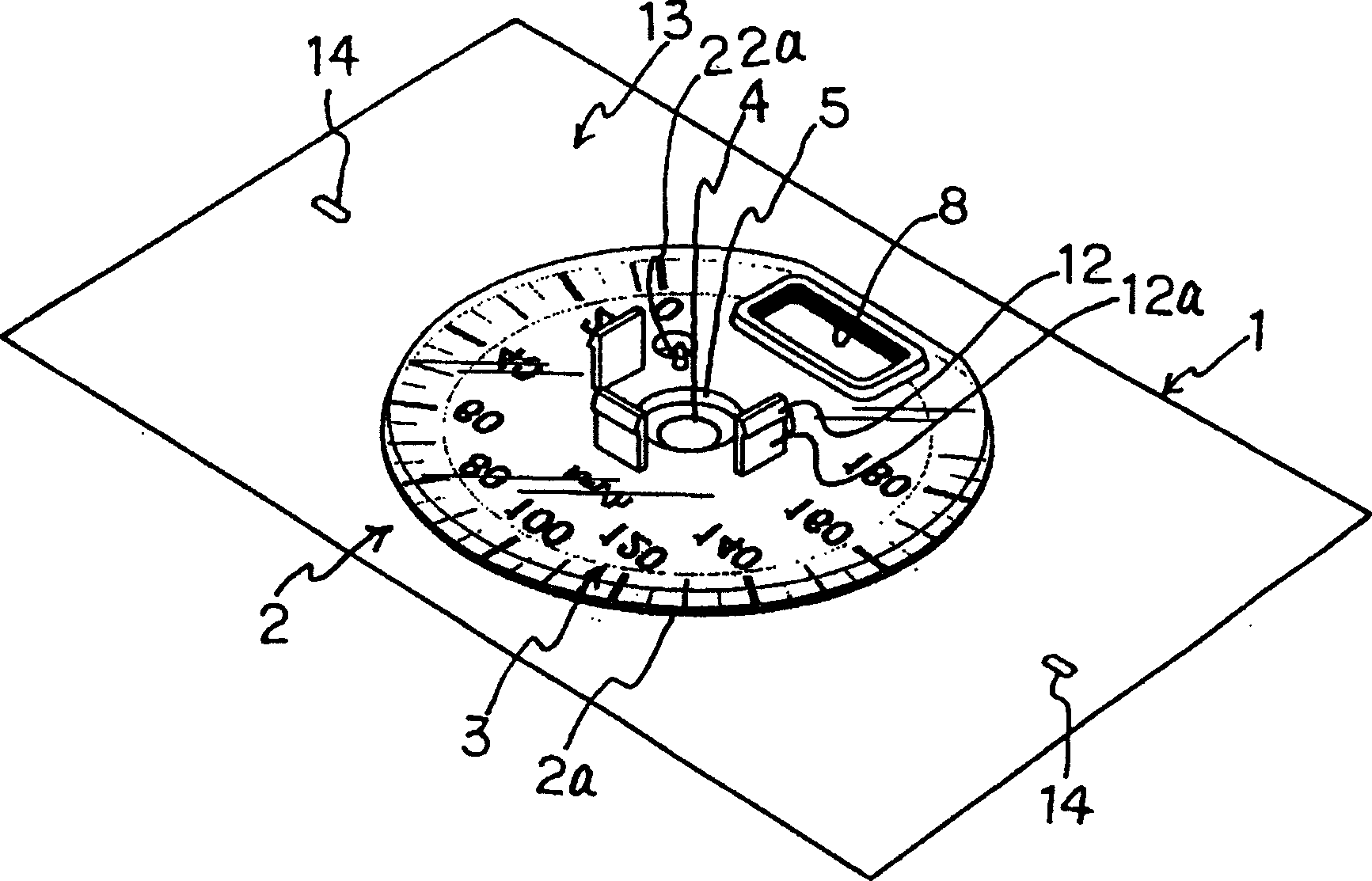

[0069] Such as Figure 7 , Figure 8 As shown, the synthetic resin molded product 1 of this embodiment is suitable for, for example, a panel for an automobile speedometer, and a small-diameter hole for inserting a rotating shaft 6 for a meter pointer is formed at the center of the synthetic resin plate 2 constituting the surface. 4. Scale and numerical value 7 are formed around it, and a window 8 etc. for the odometer is formed at the lower part. The above points are the same as those of the above-mentioned embodiment.

[0070] However, in this embodiment, the outer periphery of the synthetic resin plate 2 is previously extruded and punched so that it does not have the surrounding non-molded portion 13 as in the above-mentioned embodiment, and on the outer periphery of the synthetic resin molded product 1 The shape 2a is molded in a state where the synthetic resin plate 2 is covered on the side.

[0071] In addition, if Figure 9 As shown, in this manufacturing method, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com