Vacuum ladle

A vacuum ladle and bag body technology, which is used in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of many times of transportation, not high temperature resistance, easy to generate internal stress, etc., and save the times of transportation. , high temperature resistant service life, reliable self-locking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

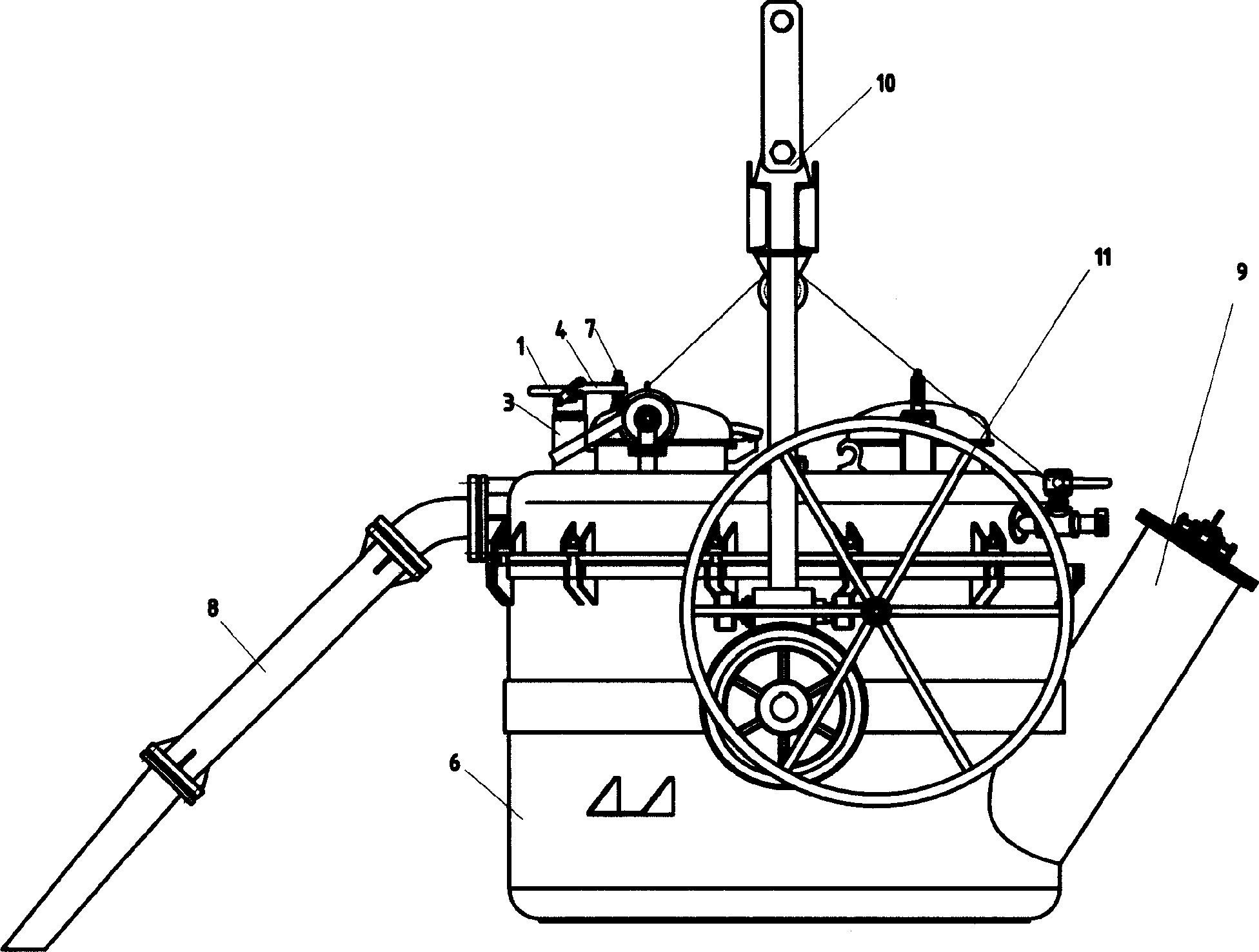

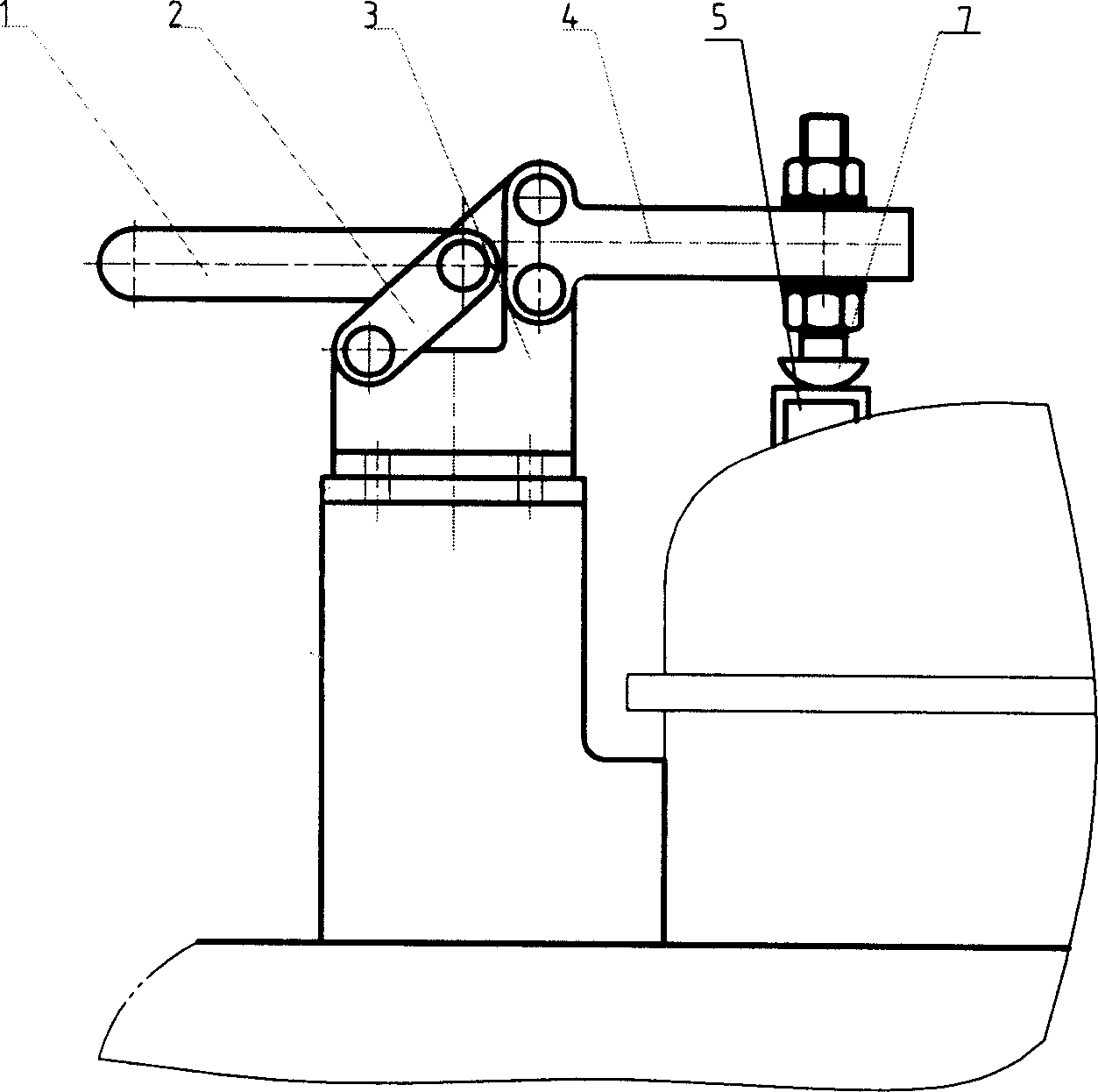

[0012] Vacuum ladle as shown in the figure, the nozzle, aluminum suction pipe 8 and aluminum outlet 9 are welded and fixed on the ladle body 6, the aluminum suction pipe is made of heat-resistant cast iron aluminum suction pipe, the hoisting assembly 10 is connected to the frame, and the There is a worm and gear transmission mechanism 11. The upper and lower heads of the package body are formed by spinning, with a volume of 12 tons. The locking device on the cover adopts toggle-type compression. The other end of the plate is hinged with the toggle handle 1, the front end of the toggle handle is fixedly connected with one end of the transverse side of the T-shaped guide bar 4, the other end of the transverse side of the guide bar is hinged with the side plate, and the hard side of the guide bar is equipped with a large semi-round head square neck Bolt 7, channel steel boss 5 is fixed on the bag cover corresponding to the bolt, and the bolt cap compresses the boss.

[0013] When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com