Degradable insulating wire cable material with heat resistance and durability

An insulated wire and durability technology, applied in the direction of organic insulators, insulators, plastic/resin/wax insulators, etc., can solve the problems of poor mechanical properties, poor molding performance, poor compatibility, etc., and achieve physical and mechanical properties. There is performance, the effect of improving durability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0029] Embodiments 1 to 4: A degradable insulating wire and cable material with heat resistance and durability, consisting of the following components by weight:

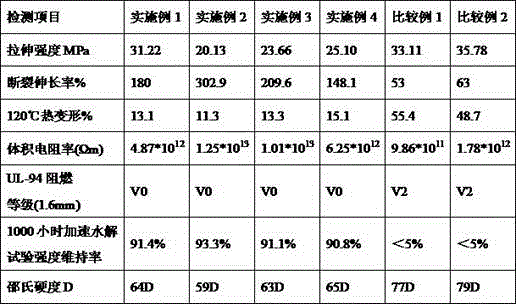

[0030] Table 1

[0031]

[0032] The above-mentioned L-polylactic acid and D-polylactic acid have a weight average molecular weight of 100,000 to 400,000.

Embodiment 1

[0033] Example 1 The metal deactivator is N-salicylamidophthalimide; the flame retardant is polycondensed aryl phosphate, mixed with triphenyl phosphate according to the weight ratio of 1:1; the filler is nano-dioxide A mixture of silicon and nano talcum powder.

Embodiment 2

[0034] Example 2 The metal deactivator is N,N'-bis[β(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hydrazine; the flame retardant is cyclic phosphoric acid ester, phosphorus cyanide flame retardant agent to form a mixture; the filler is mixed with nano-layered silicate and nano-calcium carbonate according to the weight ratio of 1:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com