Structure of water tank of having heat sink in liquid cooling type

A cooling device and water tank technology, applied in the direction of instruments, electrical digital data processing, digital data processing components, etc., can solve the problems of loss of grain structure precision, high cost, and reduced structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the technical content of the present invention, a preferred specific embodiment is given as follows.

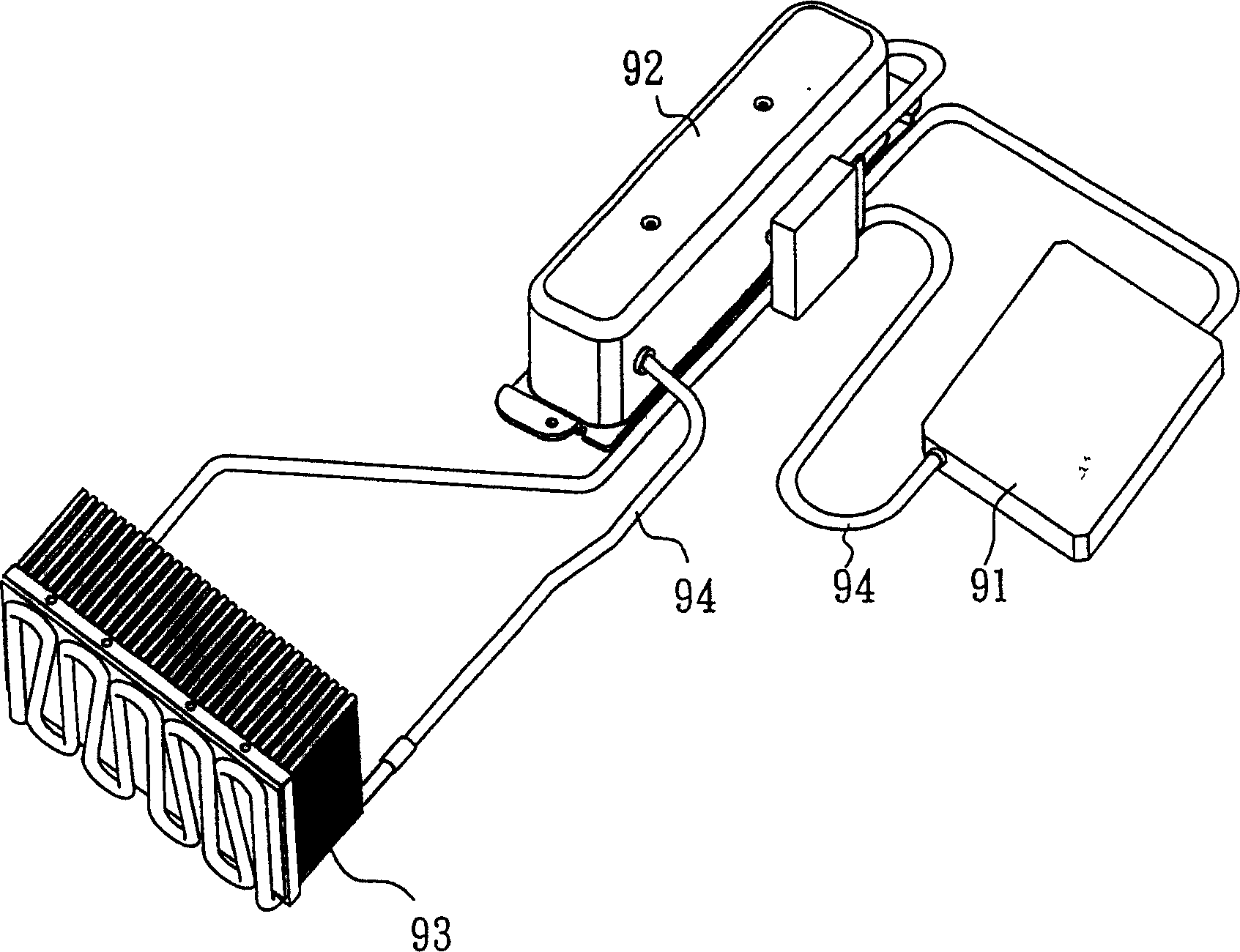

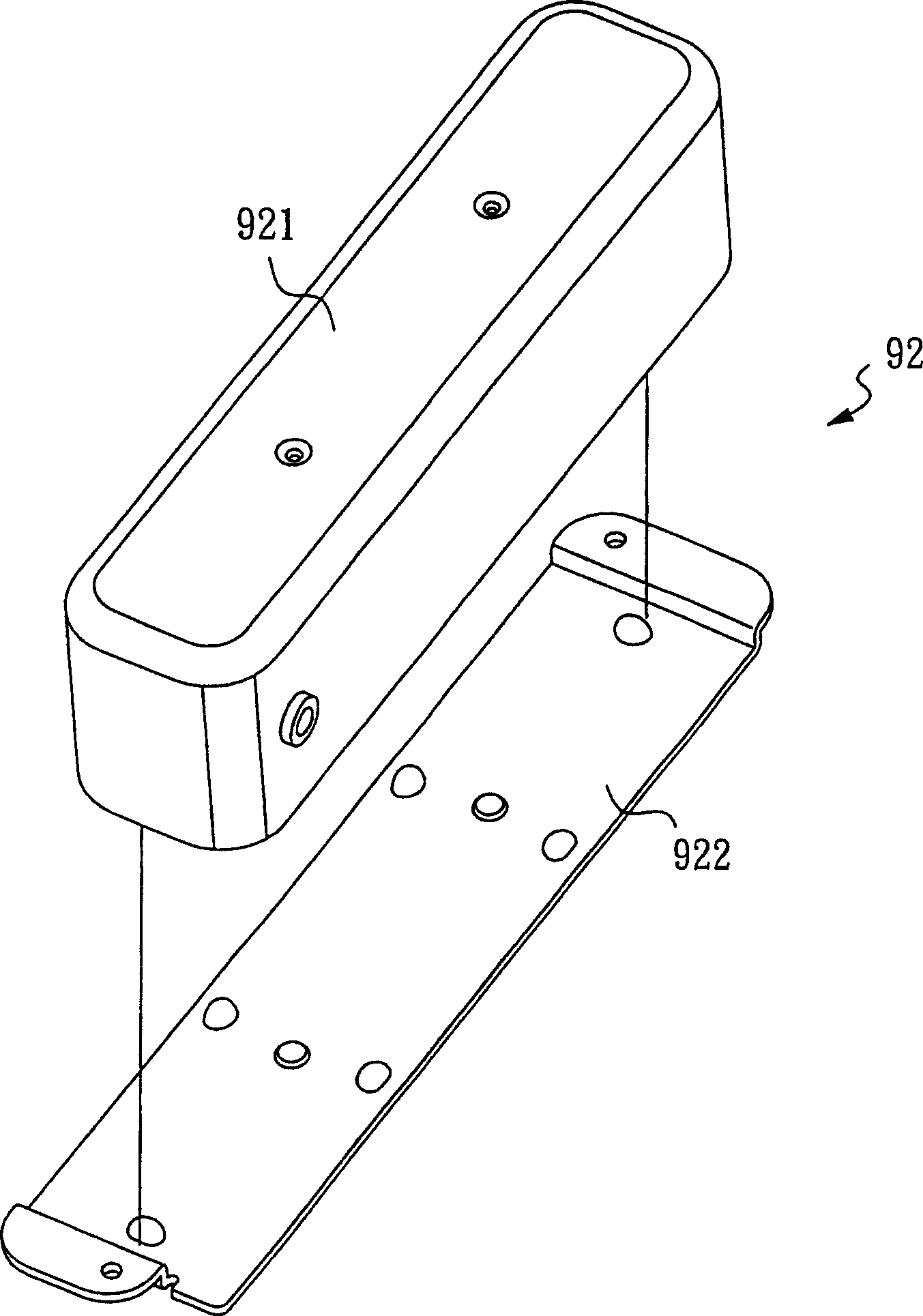

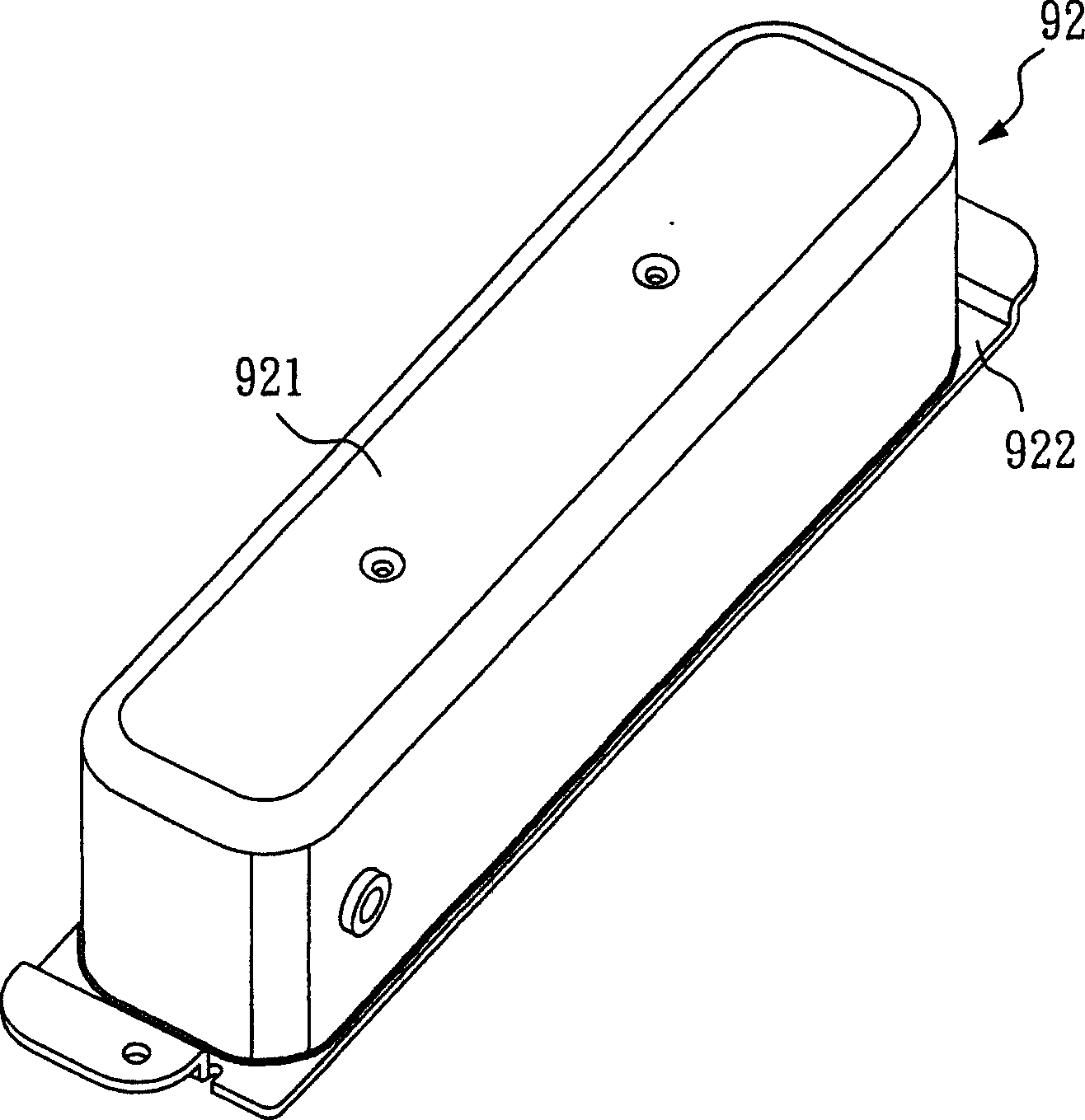

[0019] Please refer to FIG. 4 , which is an exploded perspective view of the present invention, which shows a water tank structure of a liquid-cooled heat sink of the present invention, which mainly includes a hollow tube body 1 and two side plates 2 , 3 .

[0020] Please also refer to Figure 4, Figure 5 It is a schematic diagram of the manufacturing method of the hollow tube body of the present invention, and Figure 6 It is a three-dimensional combination diagram of the present invention, wherein, the above-mentioned hollow pipe body 1 is a square pipe body and is formed by extrusion (such as Figure 5 shown), and the hollow pipe body 1 is made of copper metal, of course, other metal materials, such as aluminum, can also be used. In addition, the aforementioned hollow tube body 1 includes an internal chamber 11, and an opening 12, 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com