Injector screw axial pulse displacement method and apparatus

An axial displacement, injection machine technology, applied in the field of the axial pulsation displacement of the screw of the injection machine, can solve the problems of inconvenient adjustment of vibration force and poor adjustment effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

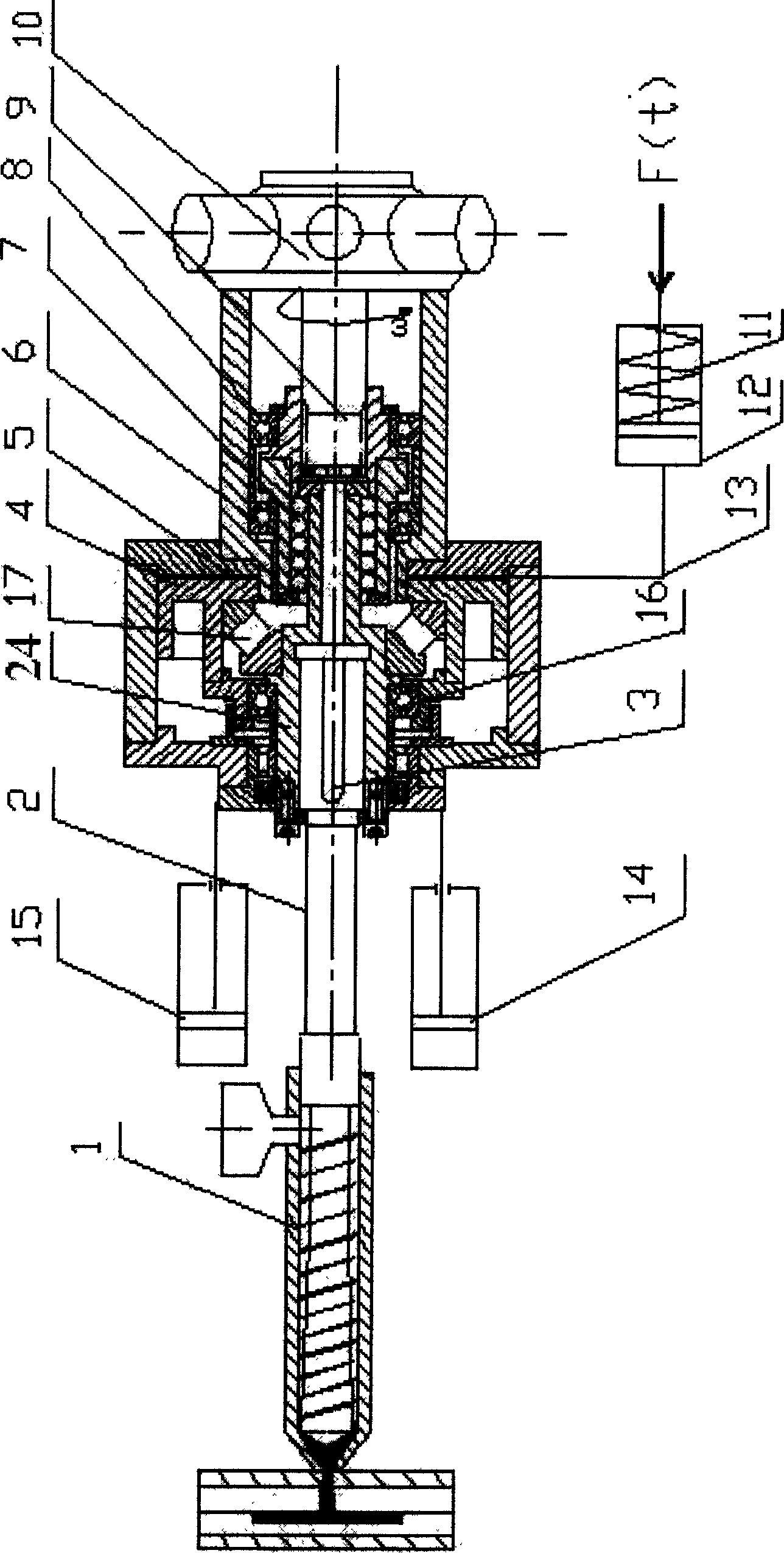

Embodiment 1

[0015] Such as figure 1 As shown, the screw axial pulsation displacement device of the injection machine is a structure in which the piston of the vibration cylinder does not rotate. The front end of the piston shaft 24 of the excitation cylinder 5 fixed on the hydraulic motor base is connected with the power transmission shaft 2 of the injection screw 1 through the key 3 and is positioned mutually in the axial direction; The spline 7 is connected with the output shaft 9 of the hydraulic motor 10 , and the rolling spline 7 is supported by positioning bearings 6 and 8 . Rotation drives the rolling spline 7 connected to the output shaft 9 of the hydraulic motor 10, so that the injection screw 1 can either rotate or simultaneously or independently perform axial displacement. The piston 4 of the vibration cylinder is supported axially and radially by the tapered roller self-aligning bearing 17, positioned and installed on the piston shaft 24 of the vibration cylinder through the ...

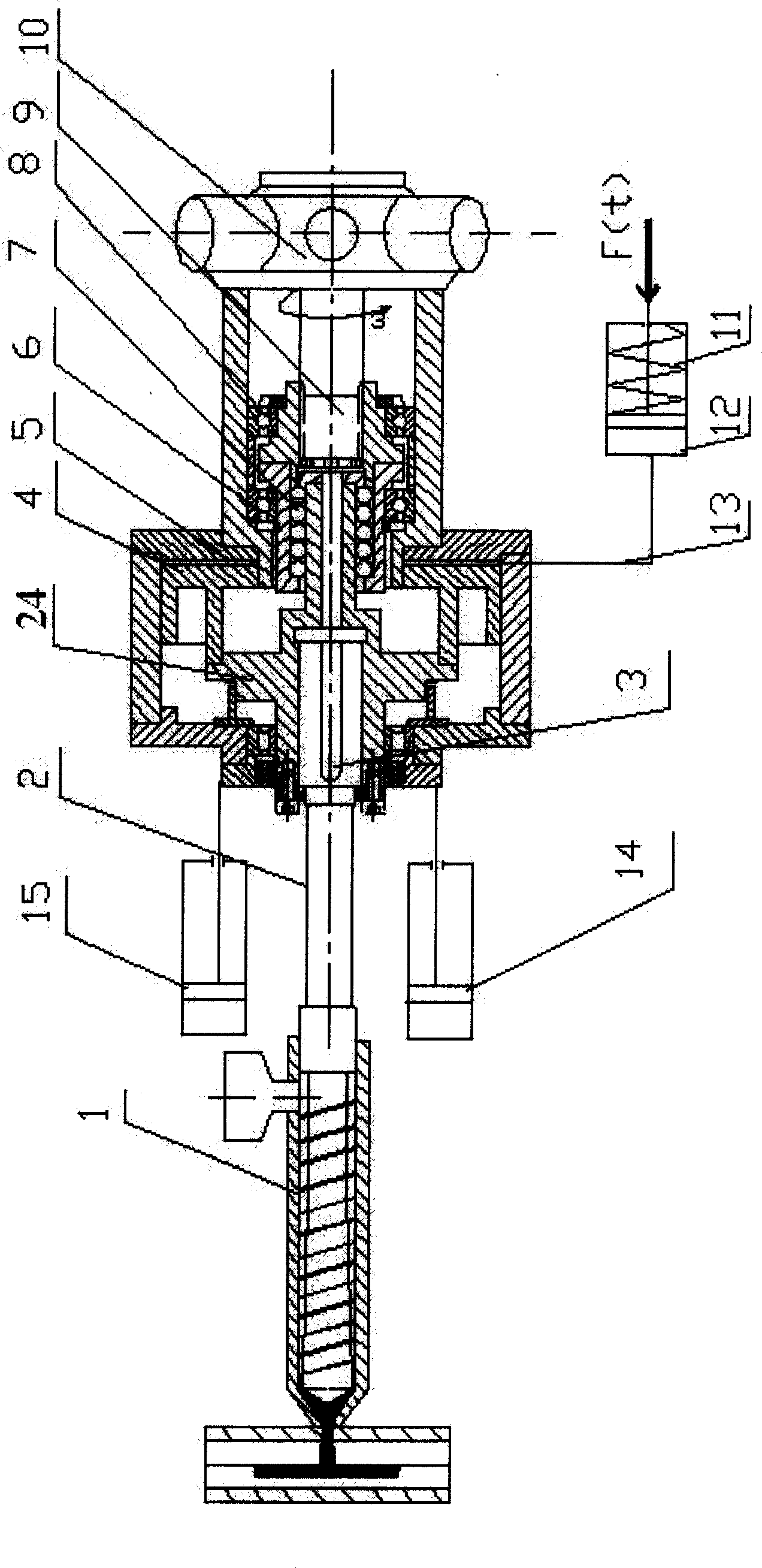

Embodiment 2

[0025] Such as figure 2As shown, it is the structural form of the vibration cylinder piston rotation. The front end of the piston shaft 24 of the excitation cylinder 5 fixed on the hydraulic motor base is connected with the power transmission shaft 2 of the injection screw 1 through the key 3 and is positioned mutually in the axial direction; The spline 7 is connected with the output shaft 9 of the hydraulic motor 10 , and the rolling spline 7 is supported by positioning bearings 6 and 8 . Rotation drives the rolling spline 7 connected to the output shaft 9 of the hydraulic motor 10, so that the injection screw 1 can either rotate or simultaneously or independently perform axial displacement. The vibration excitation cylinder piston 4 is not independently supported by bearings, and is fixedly connected with the vibration excitation cylinder piston shaft 24, so that the vibration excitation cylinder piston shaft 24 and the vibration excitation cylinder piston 4 can axially vi...

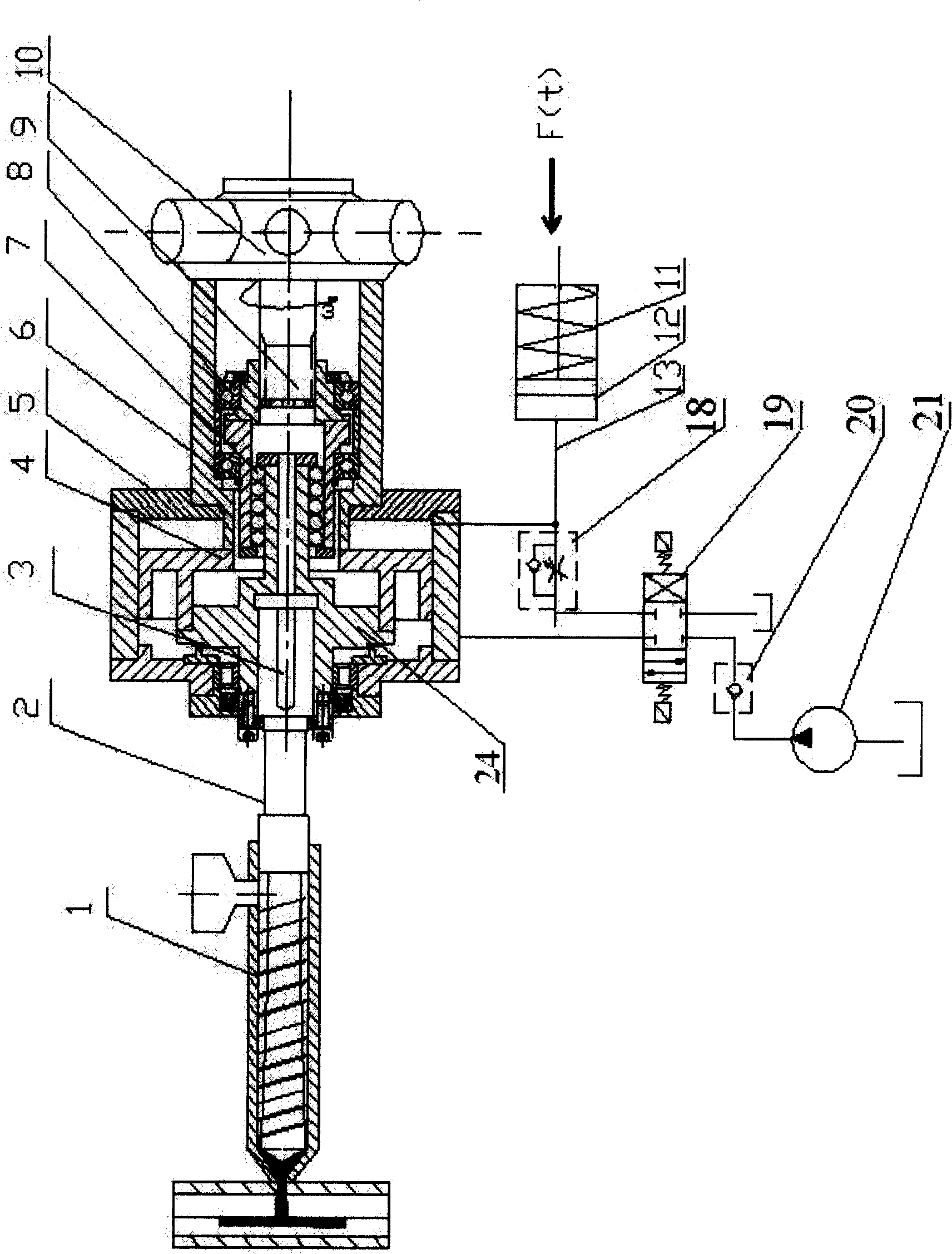

Embodiment 3

[0029] Such as image 3 The structure shown is a single cylinder direct injection. It includes an excitation oil cylinder 5 fixed on the injection seat and an excitation source oil cylinder 12 that provides axial vibration under the action of an alternating external force F. The axial vibration oil pressure generated by the excitation source cylinder 12 of axial vibration is connected to the injection cylinder 5 through an oil pipe 13 . The power transmission shaft 2 of the injection screw 1 is connected with the piston shaft 24 of the excitation cylinder 5 through the key 3, and the piston shaft 24 is fixedly connected with the piston 4. Thus, the periodic pulsation generated by the exciting oil cylinder acts on the screw 1 through the piston shaft 24 and the power transmission shaft 2, so that the screw 1 can perform periodic axial vibration while axially displacing. After the axial displacement and axial vibration are superimposed Make screw 1 make axial pulsating displac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com